We have an extensive range of industrial masking tapes which cover the needs of many sectors, including automotive, transport, construction, consumer appliances, metal working, and furniture production. And our high-temperature masking tapes for applications such as powder coating and printed circuit board manufacturing offer ease of use, residue-free removal, as well as weather and heat resistance.

Generally, the choice of which masking tape to use depends on the nature of the application, the paint, or coating system used, and the temperature at which it dries or cures. That is why we have developed masking tapes with a choice of adhesives and backings (e.g., cloth, paper, or filmic). While we primarily use rubber adhesives, silicone adhesives are more suitable for high-temperature masking above 160 °C (320 °F). And you should always be able to remove masking tape cleanly, without leaving residues, and without damaging the substrate it is masking.

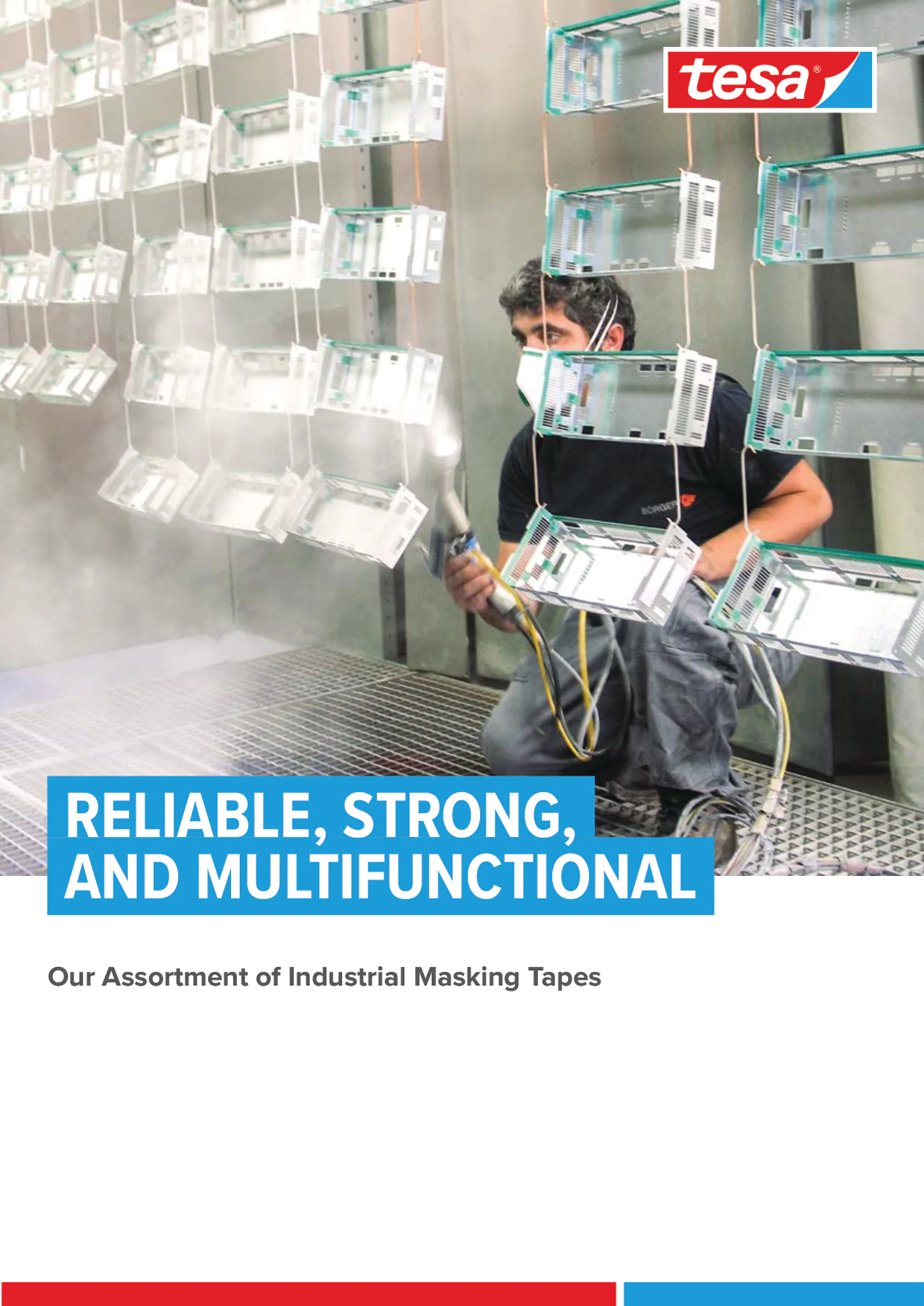

For some masking applications, such as sandblasting,high temperature resistance is not a prerequisite. In this case, a strong, thick backing which is resistant to abrasion under high pressure is vital.