PE foam tapes

for challenging

industrial applications

Our PE foam tapes have long proven their value to the electronics, automotive, building, appliance, and flexo printing industries. Why? Because PE foam tapes offer excellent shear strength in all directions, even under harsh environmental conditions. They also aid alignment and damp vibrations to improve precision. Furthermore, our PE foam tapes develop high adhesive strength quickly with limited pressure, offering greater process tolerance.

As PE foam tapes use polyethylene (PE) foam as a carrier material, they do not absorb water or air thanks to their closed-cell structure. This makes PE foam tapes ideal for demanding applications that require outstanding insulation, sealing, cushioning, or protection from moisture and dust. What’s more, properties such as impact resistance, bonding performance, and durability all feature in our PE foam tape portfolio.

PE foam tapes are used in many industrial applications

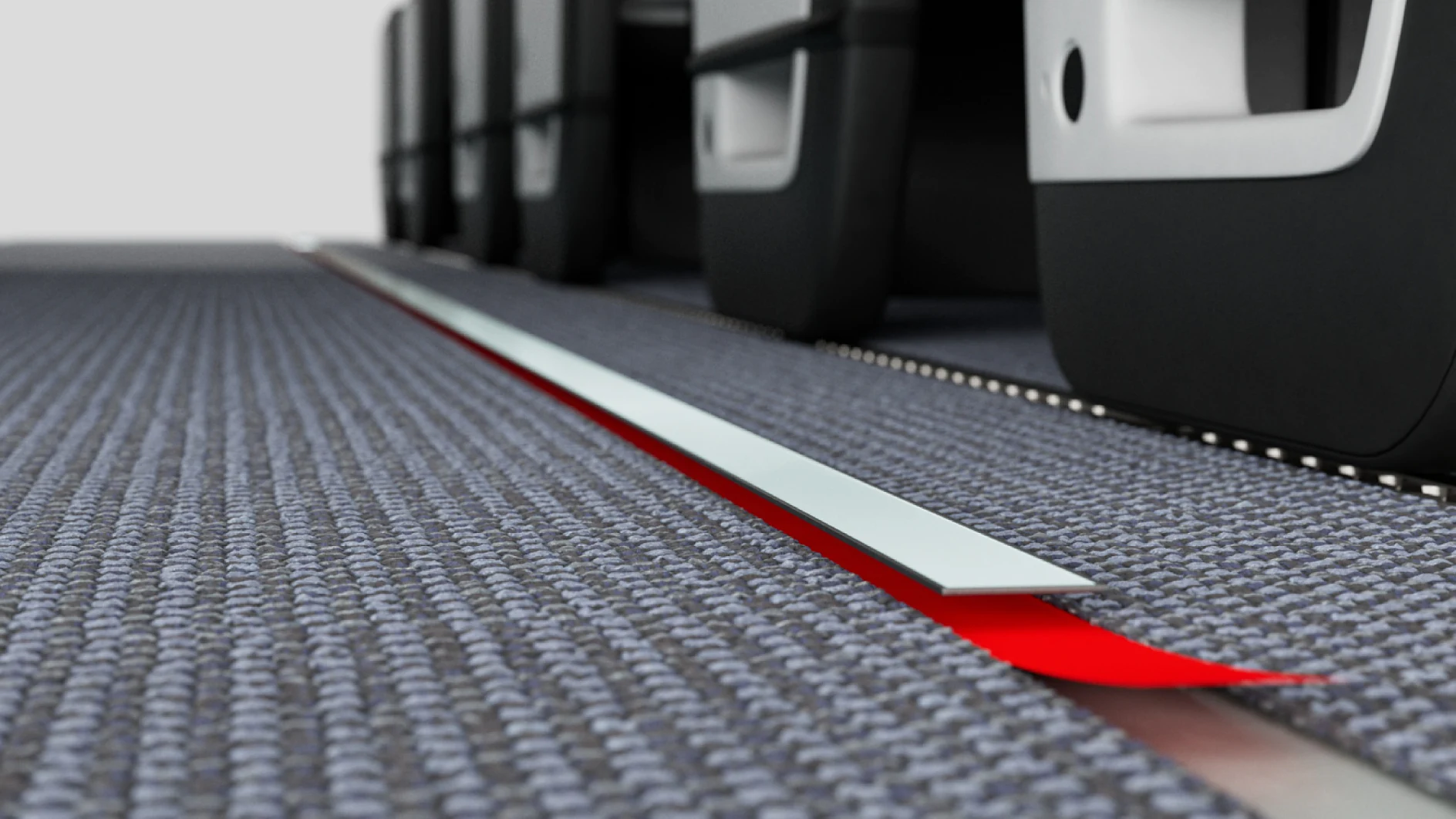

PE foam tapes are relied upon in many industries thanks to their flexible, secure bonding performance, especially when mounting parts on uneven or curved surfaces. They show excellent cushioning properties with no sliding or creep.

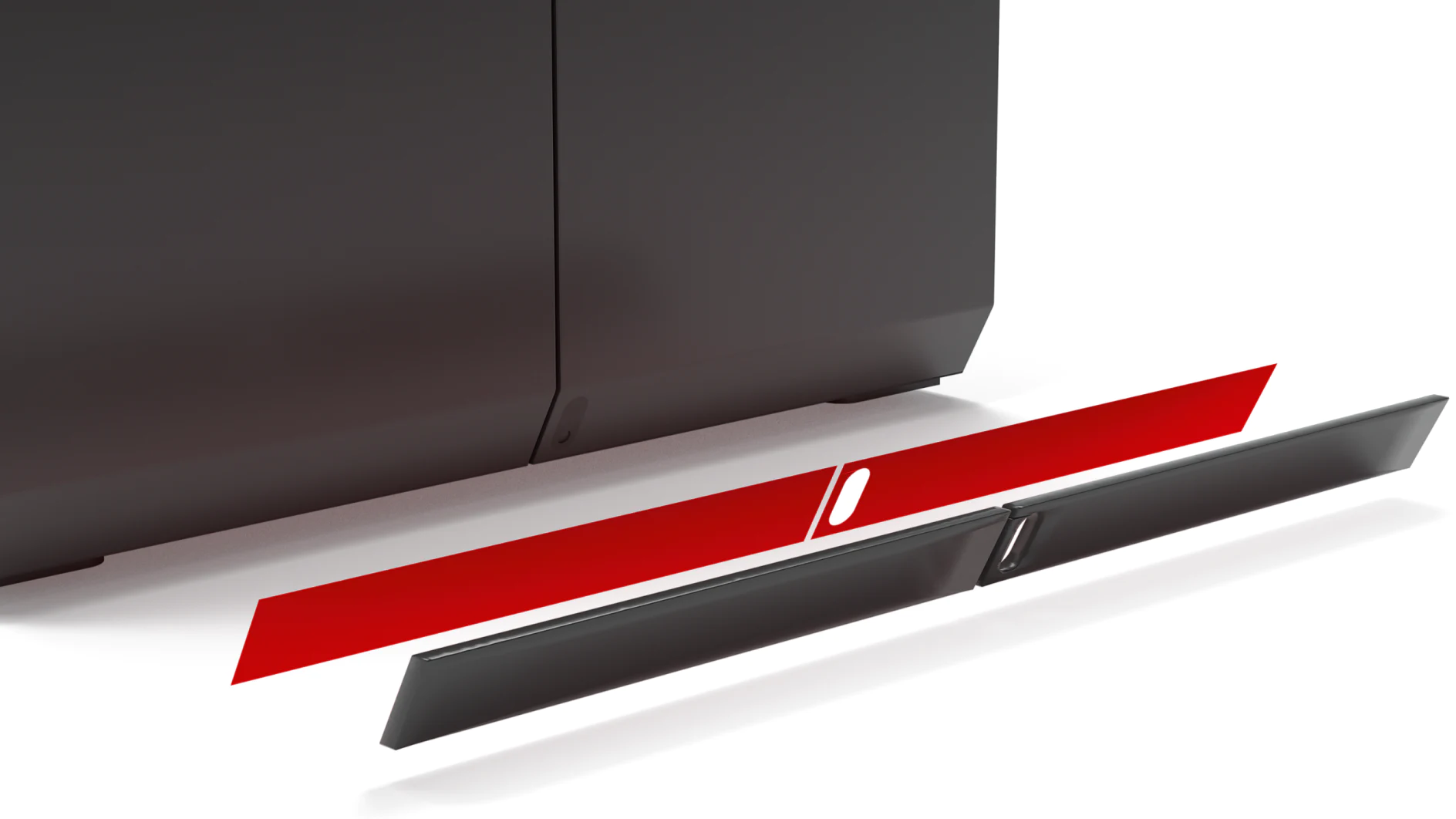

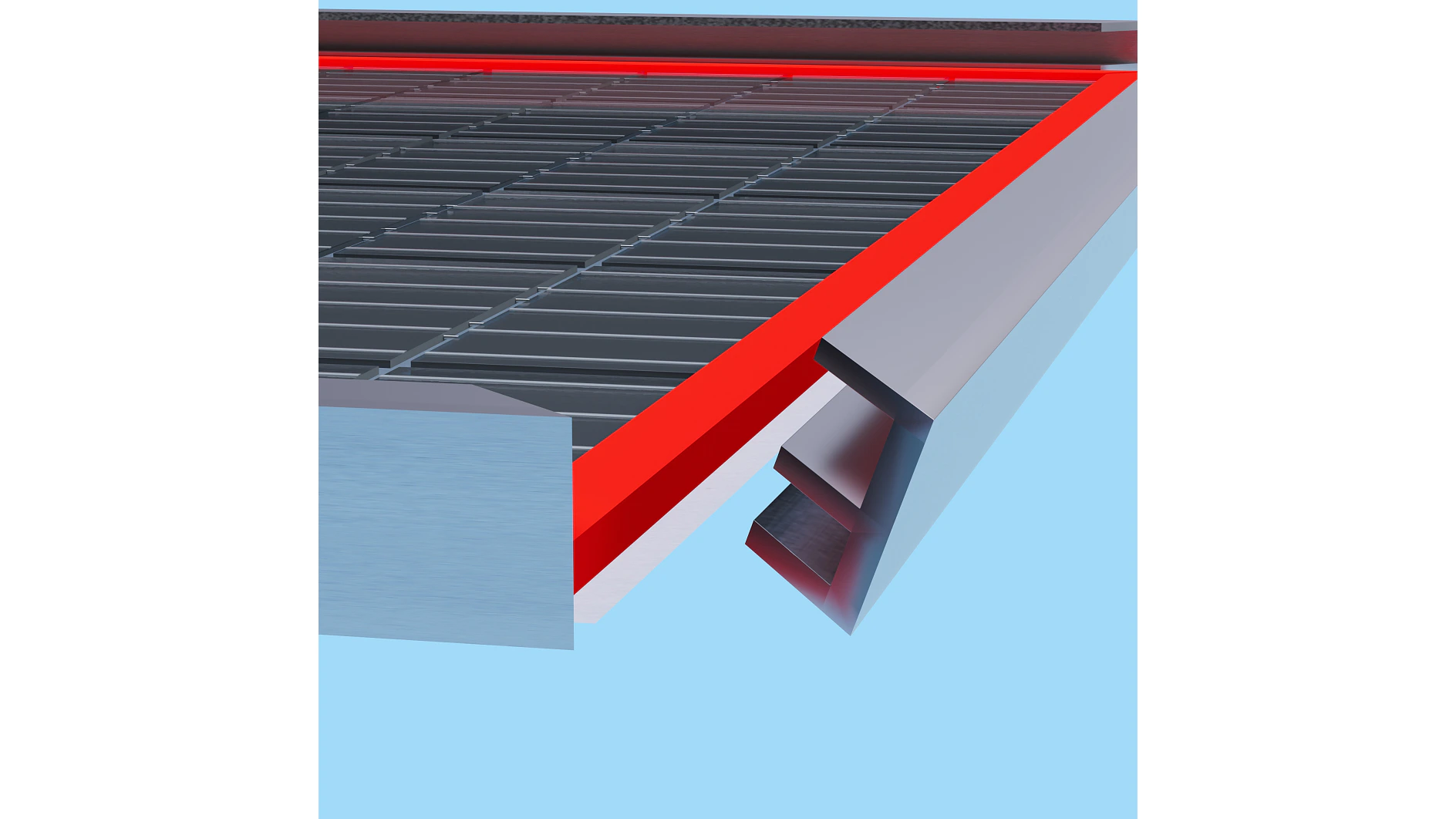

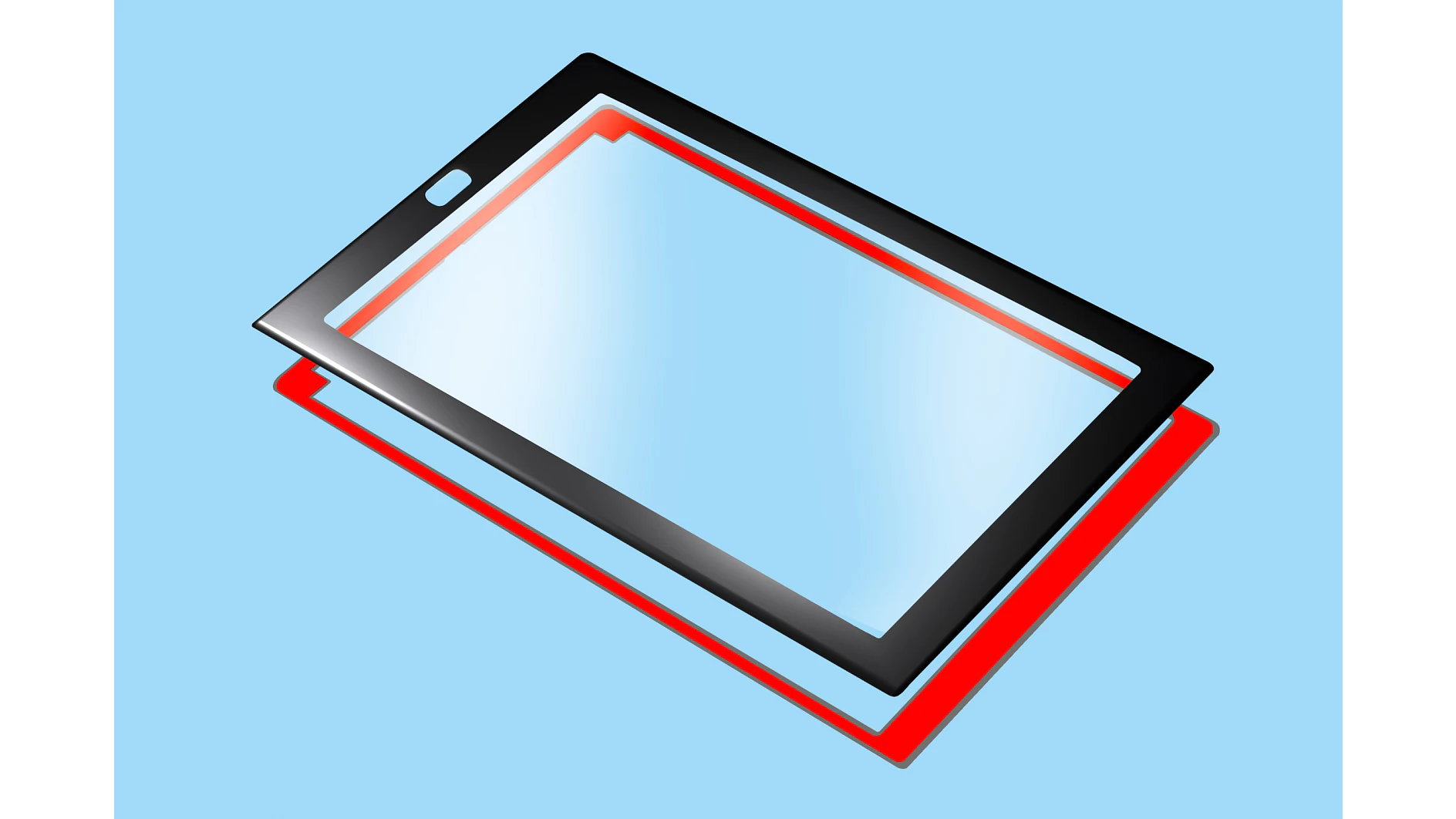

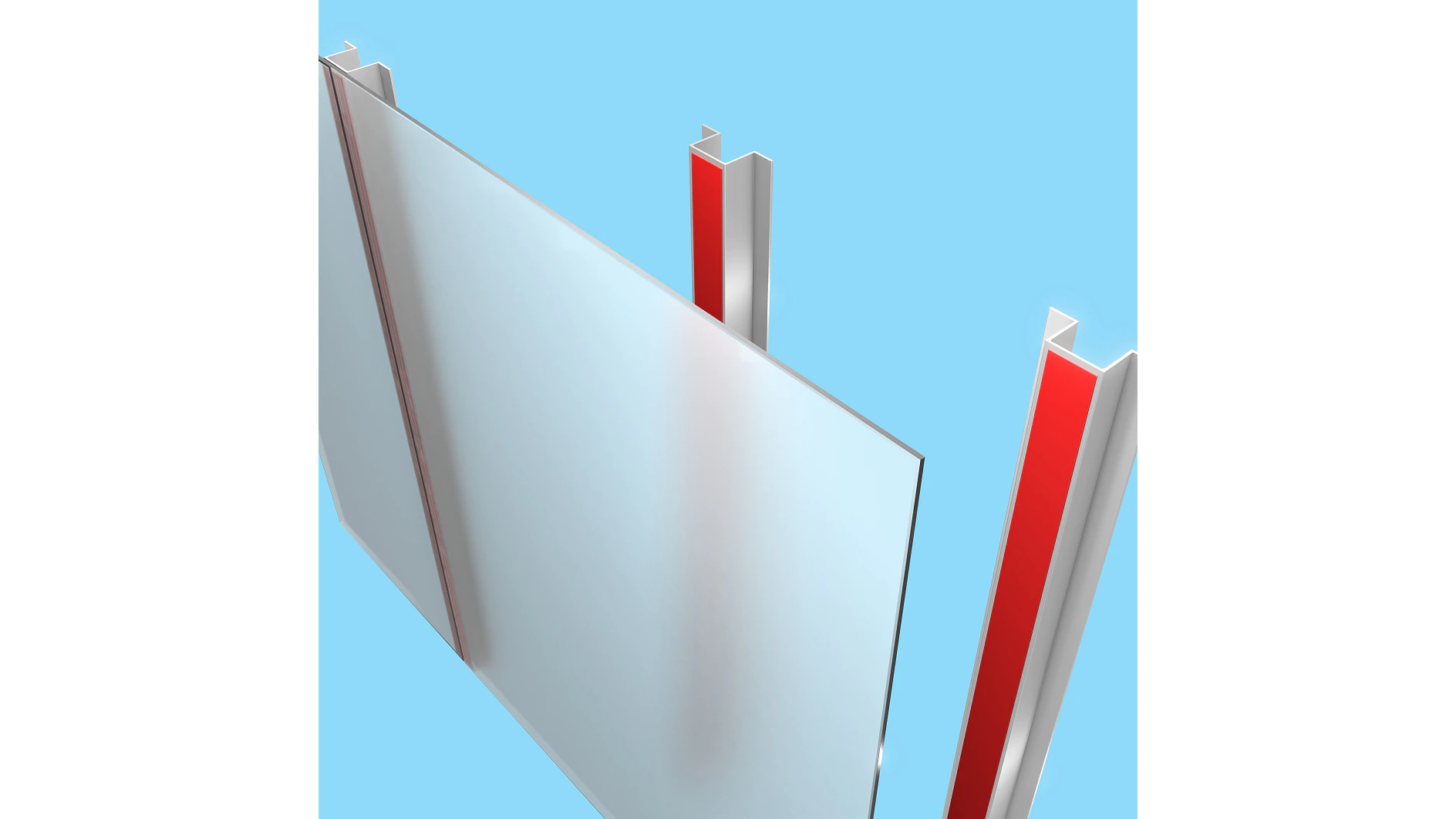

In the automotive sector, PE foam tapes provide very good bonding to plastic and clear coat for exterior parts such as emblems and trim. Vehicle manufacturers also use PE foam tapes to fill gaps and seal electronics and instrument clusters. PE foam tapes are often used in the appliances industry to mount trims, emblems, displays, and other components. Manufacturers of solar modules use these tapes for example for module frame bonding. The electronics industry relies on PE foam tapes to mount batteries, covers, lenses, and touch panels in consumer electronics such as smartphones, tablets, smartwatches, TVs, etc.

There are many more industrial applications for PE foam tapes. Please reach out to our technical experts to find a feasible solution for your specific demand.

Some features of our PE foam tapes

PE foam tapes have exceptional adhesive strength and temperature resistance, making them suitable for use in extreme temperature and humidity environments. In addition, PE foam tapes are easy to activate and have high immediate bonding performance, even under limited pressure conditions. They provide optimal shear resistance and anti-lifting, ensuring a secure bonding performance. Furthermore, they offer outstanding shock performance and splintering protection, as well as tight sealing against water, humidity, and dust. Finally, they have good rework and die-cutability, making them ideal for complex designs.

PE foam tapes for industrial applications

Browse our assortment of PE foam tapes and find a solutions that meets your demands. The different series we are producing come in different thickness, colors and performance profiles. Make use of our product finder to identify solutions that suit your project.

Individual PE Foam tape developement - an example

For decades, adhesive tapes that needed a primer were standard in the automotive industry for bonding small plastic parts with low and medium surface energy. A procedure that was both time-consuming and hazardous.

After listening to the needs of the sector, tesa developed the specialized double-sided PE foam tape tesa® 649xx so manufacturers can skip the primer application entirely. The foam tapes’ high-performance adhesive enables secure bonding of low surface energy materials (LSE), like PP or EPDM surfaces, and medium surface energy (MSE), like ABS surfaces. All without the need for a primer.

This innovation from tesa greatly increases application efficiency without sacrificing adhesion. It stands out as a prime example of our distinct sense for different markets and their requirements. The PE foam tape reaches ultimate bonding strength right away with no need for dwell time, improving production turnaround times as a result. It also works effectively in both hot and cold environments, making it the superior choice for plants where temperatures can be extreme. What’s more, it also improves the working environment by removing harmful materials and reduces the need to maintain extraction equipment.

Should I choose a PE foam tape or an acrylic foam tape?

Both PE foam and acrylic foam tapes are widely used for industrial applications. PE foam tapes are often preferred for applications that require compensation of uneven surfaces, levelling of tensions and a certain shock resistance. Acrylic foam tapes in general provide an improved stress relaxation, energy absorption and higher bonding strength and are therefore used for very demanding industrial applications.

Please reach out to our technical experts to discuss your project in detail and find the best possible foam tape solution.