We are fully IATF 16949 certified and our global production network ensures reliable on-time delivery. With our global support network of engineers and customer representatives we will be by your side, anytime, anywhere. Just give us a call!

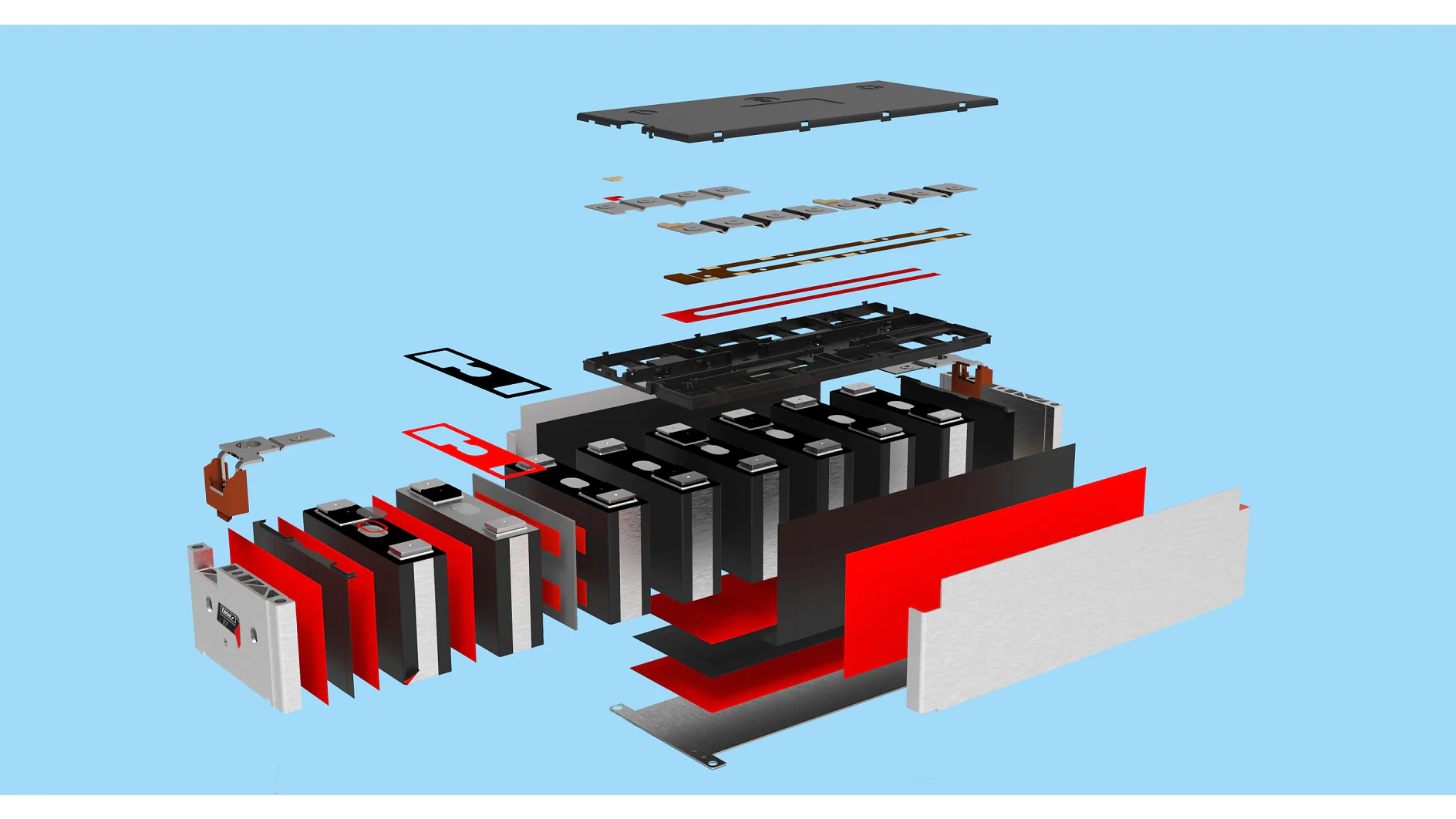

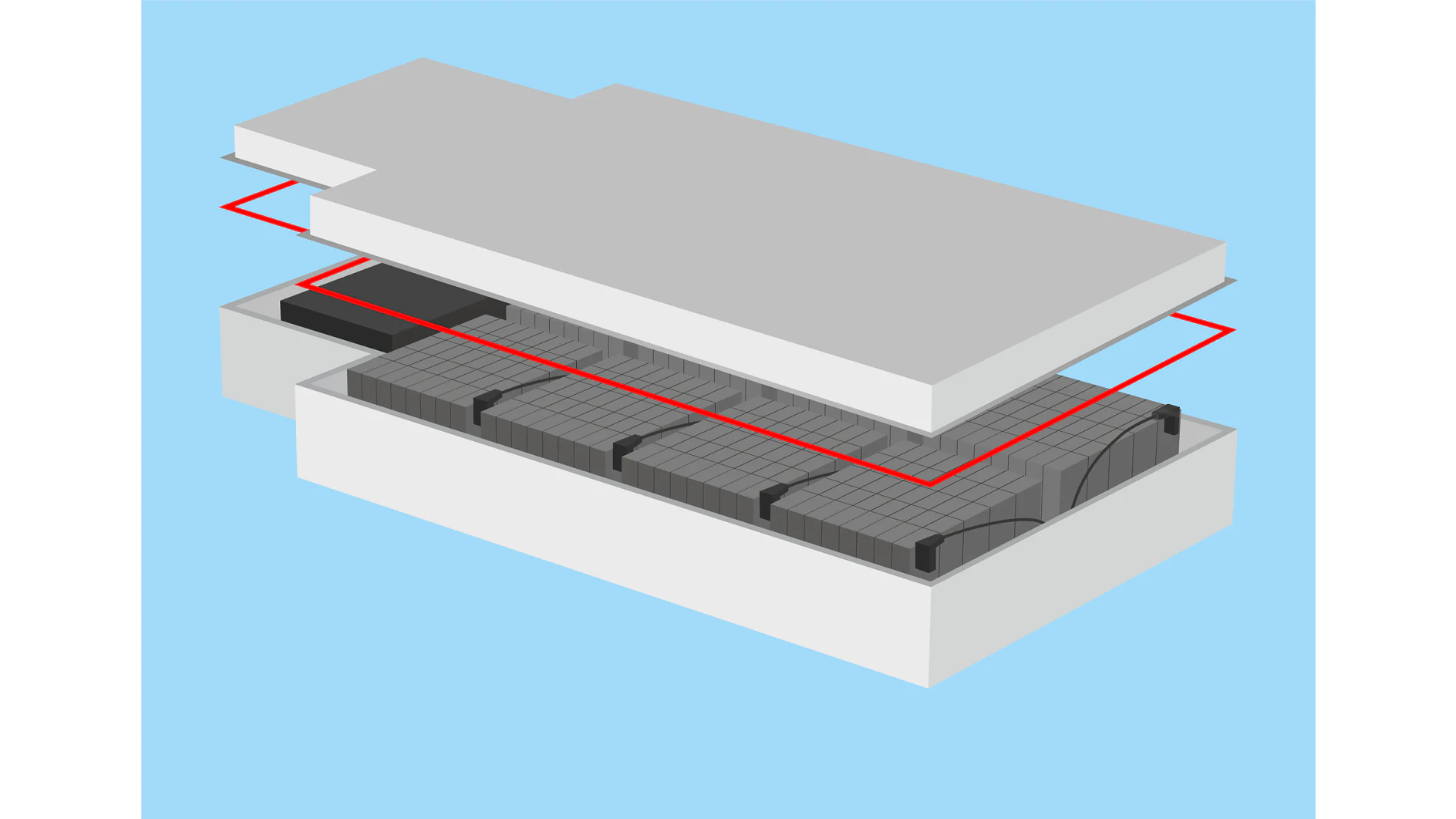

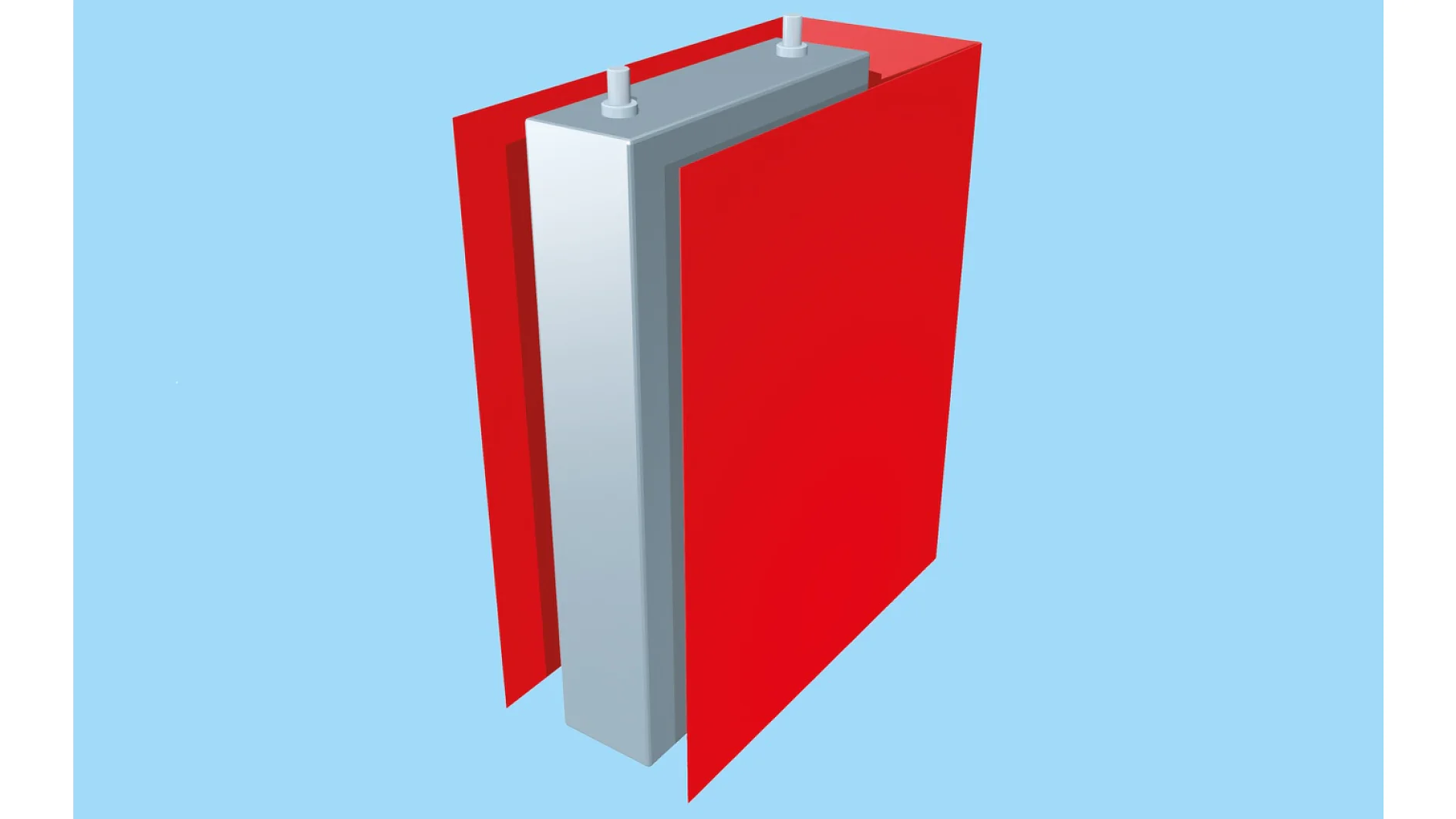

Adhesive Tape Solutions for E-Mobility

Development partner for ev-battery solutions

Automotive E-mobility Lab

Developing cutting-edge electric vehicles in India? Partner with us for reliable adhesive tape solutions and seamless production integration. At tesa India, we support the automotive industry's electrification, designing tapes to meet strict demands and innovating for electric and hybrid vehicles in collaboration with top OEMs and suppliers.

We are here for you globally

Discover the Functionality of Our Tapes

Global Support for Electrification of Vehicles' Drivetrains

Our state-of-the- art adhesive solutions are used in battery manufacturing worldwide to improve production lines, increase safety, and ensure reliability.

We support the transformation of the automotive industry towards the electrification of vehicles' drivetrains. Our adhesive tapes are specially made to fulfill demanding automotive requirements, and we are constantly developing new adhesive tapes specifically for electrical and hybrid vehicles in close cooperation with the world’s leading OEMs and tiered suppliers.

We Support You with your EV Battery Development

We Help You Design Your Process

Our experienced staff provides on-site support to develop individual, automatic application processes for an easy handling of our adhesive tape solutions in your production.

Adhesive tapes are fast to apply and do not require curing time. Constant thickness and easy optical detection are only some of the advantages they bring along.

We have implemented robot-assisted automated solutions across the automotive industry and will find a solution for your production process as well.

As an established partner to the automotive industry we hold ISO 9001 and IATF certification and many product approvals at different OEMs – just ask us.