tesa® 58395

tesa® 58395 250µm/9.8 mil thermal conductive tape

Product Features

- It provides certain thermal conductivity with its thermally conductive fillers when it is applied between heat source and heat sink to transfer the heat.

- It has very good bonding performance on polar substrate.

Product description

tesa® 58395 is a 250um/9.8 mil thermally conductive transfer tape.

This product is equipped with special acyrlic adhesive that provide certain thermal conductivity when it applies between heat source and heat sink. Besides that, it has good mounting performance on polar substrate.

Product details and specifications

Product Features

- It provides certain thermal conductivity with its thermally conductive fillers when it is applied between heat source and heat sink to transfer the heat.

- It has very good bonding performance on polar substrate.

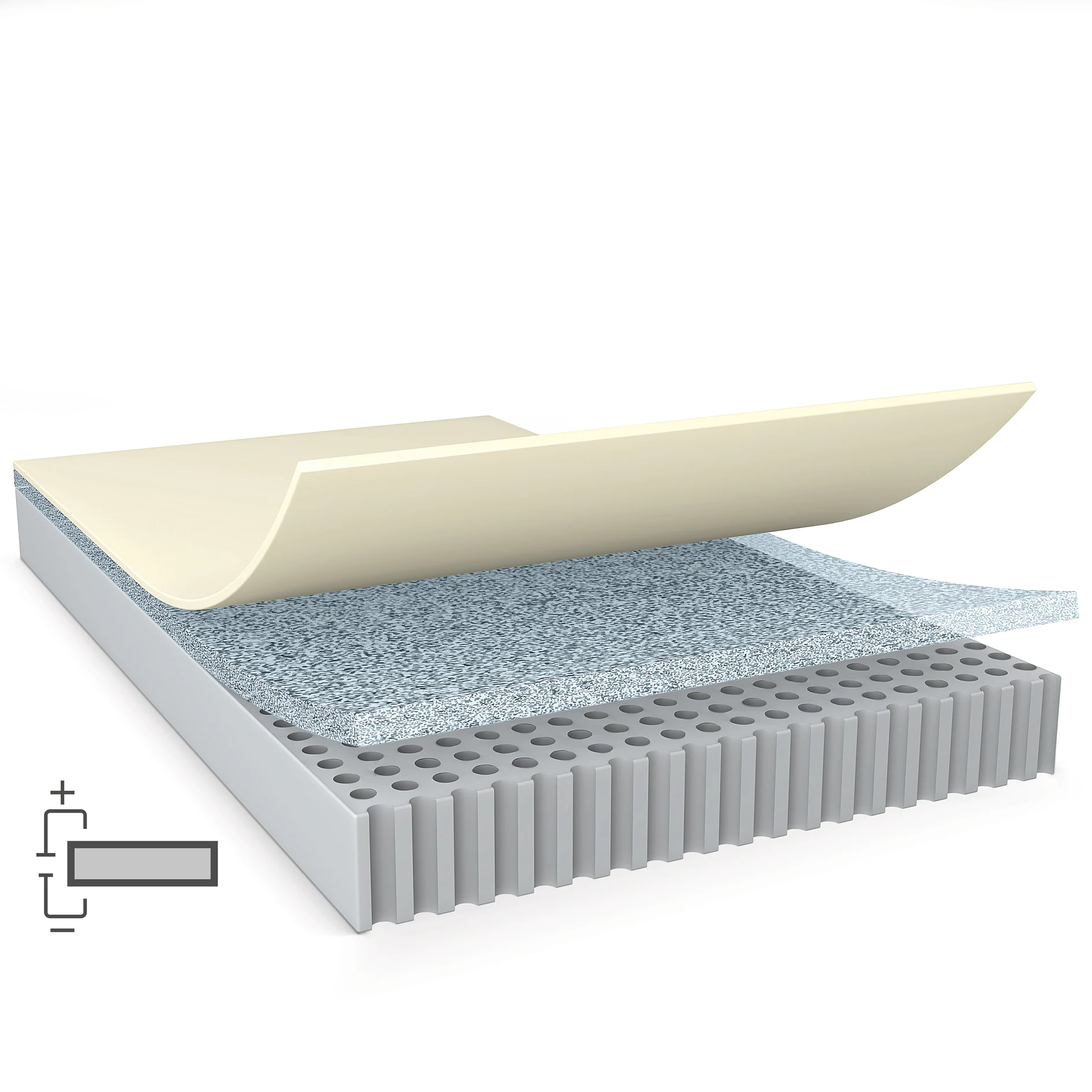

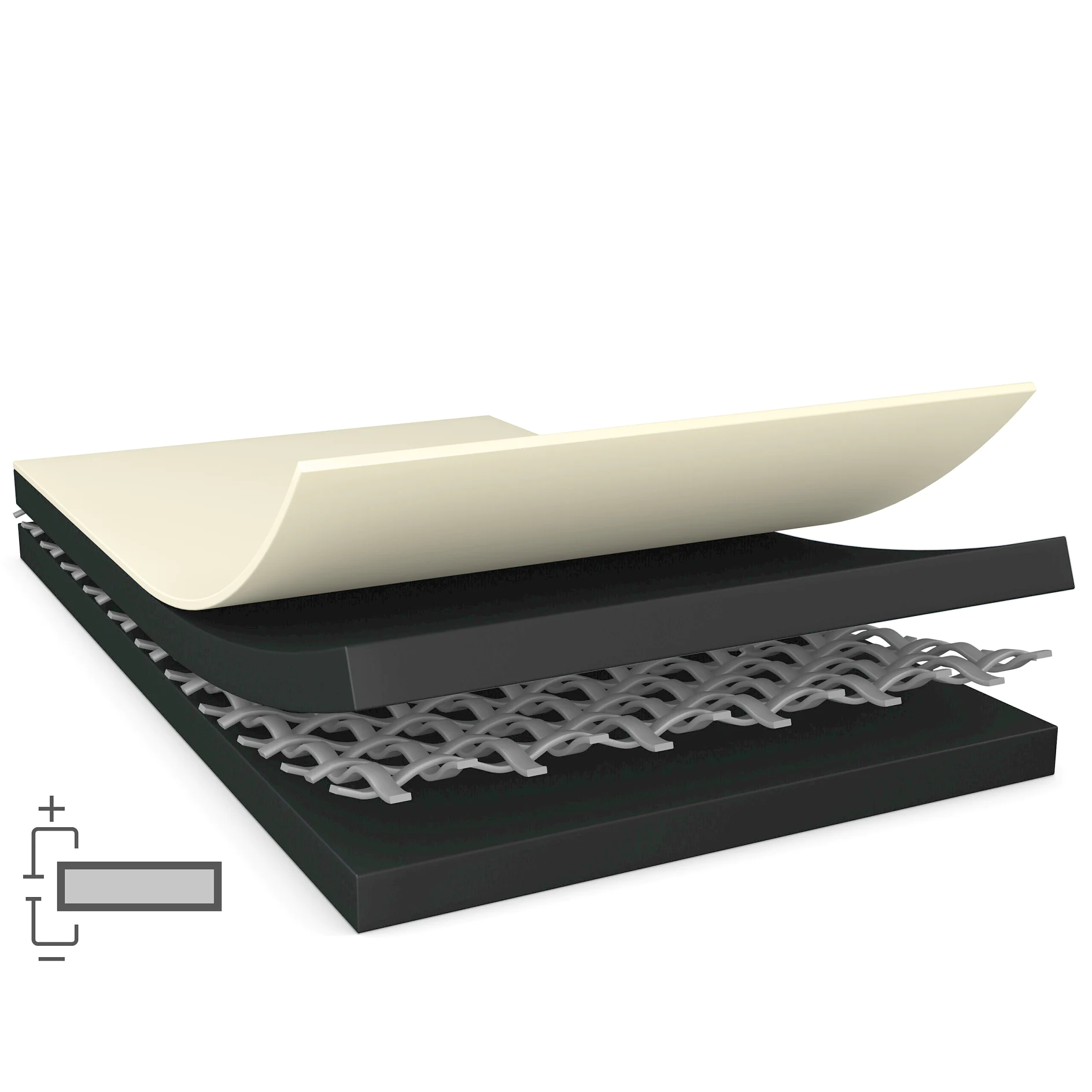

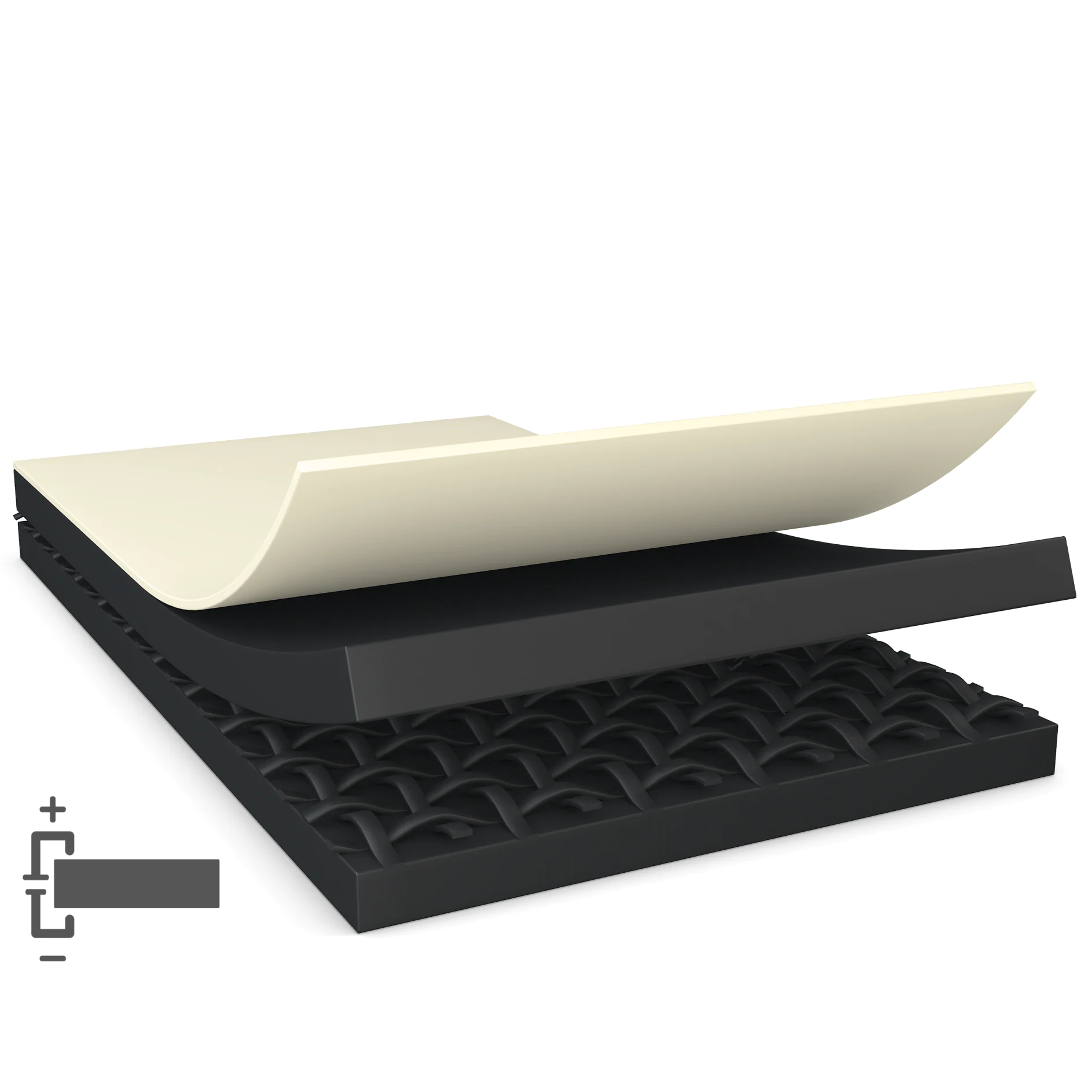

Application Fields

Applied between heat source and heat sink to transfer the heat.

- Battery module cooling plate mounting

- Power electronics unit

- FPC and PCB

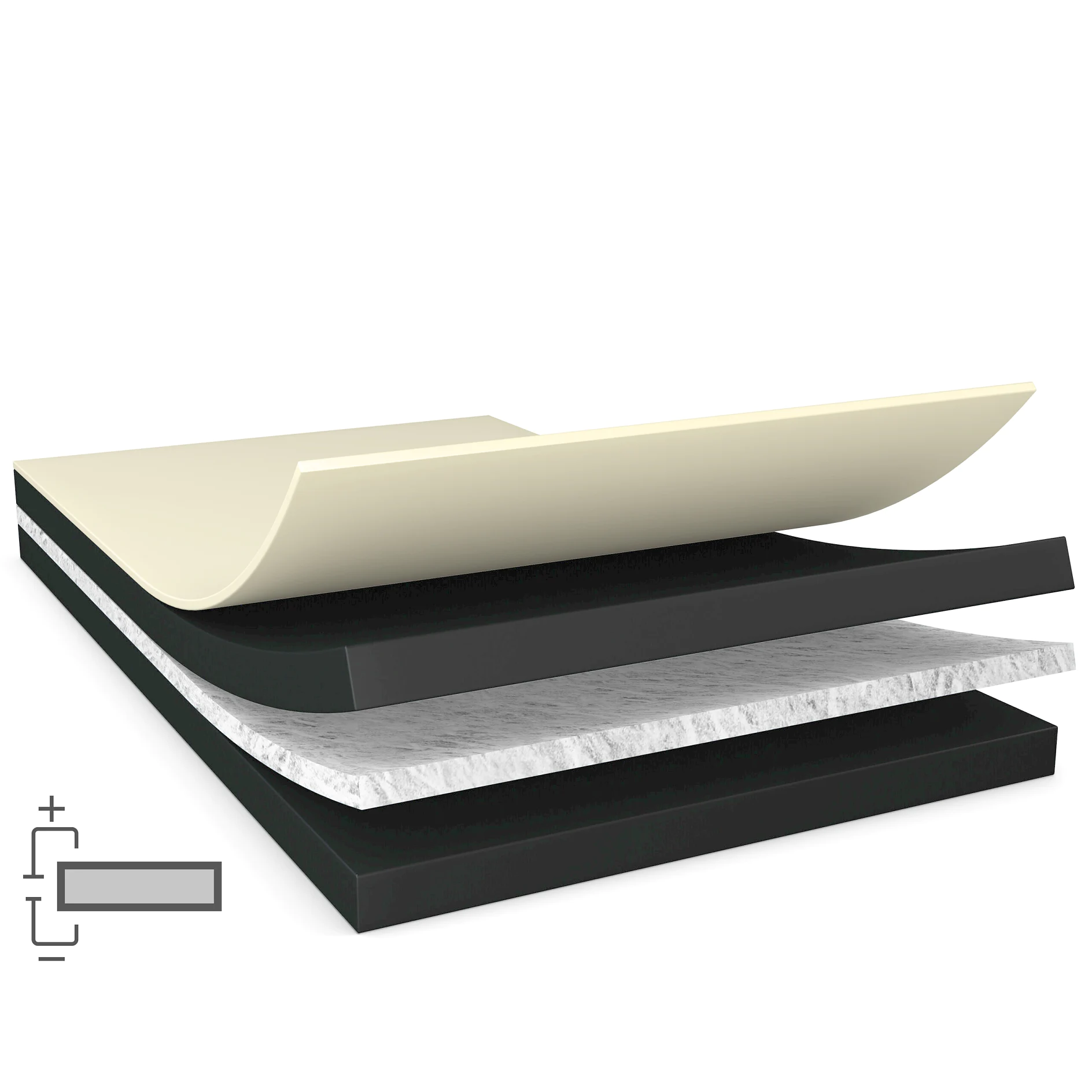

Product Construction

| Adhesive Type | acrylic |

|---|---|

| Backing material | none |

| Color | white |

| Color of liner | white |

| Liner Type | PE-coated paper |

| Thickness of liner |

5 mils

127 µm |

| Total thickness |

9.84 mils

250 µm |

Product Construction

| Adhesive Type | acrylic |

|---|---|

| Backing material | none |

| Color | white |

| Color of liner | white |

| Liner Type | PE-coated paper |

| Thickness of liner |

5 mils

127 µm |

| Total thickness |

9.84 mils

250 µm |

Properties / Performance Values

| Release of liner | easy |

|---|---|

| Temperature resistance (125°C) | very good |

| Density | 1.73 g/cm³ |

| Breakdown voltage | 4 KV |

| Flame retardancy | V2 |

| Hardness - Shore 00 | 70 STK |

| Temperature resistance short term |

302 °F

150 °C |

| Temperature resistance (-40°C) | very good |

| Thermal conductivity z-direction | 0.6 W/mK |

Properties / Performance Values

| Release of liner | easy |

|---|---|

| Temperature resistance (125°C) | very good |

| Density | 1.73 g/cm³ |

| Breakdown voltage | 4 KV |

| Flame retardancy | V2 |

| Hardness - Shore 00 | 70 STK |

| Temperature resistance short term |

302 °F

150 °C |

| Temperature resistance (-40°C) | very good |

| Thermal conductivity z-direction | 0.6 W/mK |

Adhesion to Values

| Adhesion to Aluminium (after 3 days) |

3.31 lbs/in

5.8 N/cm |

|---|---|

| Adhesion to Steel (initial) |

1.43 lbs/in

2.5 N/cm |

| Adhesion to Steel (20min @ RT, 90°) |

1.43 lbs/in

2.5 N/cm |

Adhesion to Values

| Adhesion to Aluminium (after 3 days) |

3.31 lbs/in

5.8 N/cm |

|---|---|

| Adhesion to Steel (initial) |

1.43 lbs/in

2.5 N/cm |

| Adhesion to Steel (20min @ RT, 90°) |

1.43 lbs/in

2.5 N/cm |

tesa® products prove their impressive quality day in, day out in demanding conditions and are regularly subjected to strict controls. All technical information and data above mentioned are provided to the best of our knowledge on the basis of our practical experience. They shall be considered as average values and are not appropriate for a specification. Therefore tesa SE can make no warranties, expressed or implied, including, but not limited to any implied warranty of merchantability or fitness for a particular purpose. The user is responsible for determining whether the tesa® product is fit for a particular purpose and suitable for the user’s method of application. If you are in any doubt, our technical staff will be glad to support you.

Downloads

Download the files below for more technical details and information on this product.