Advanced thermal tape solutions for today’s manufacturing challenges

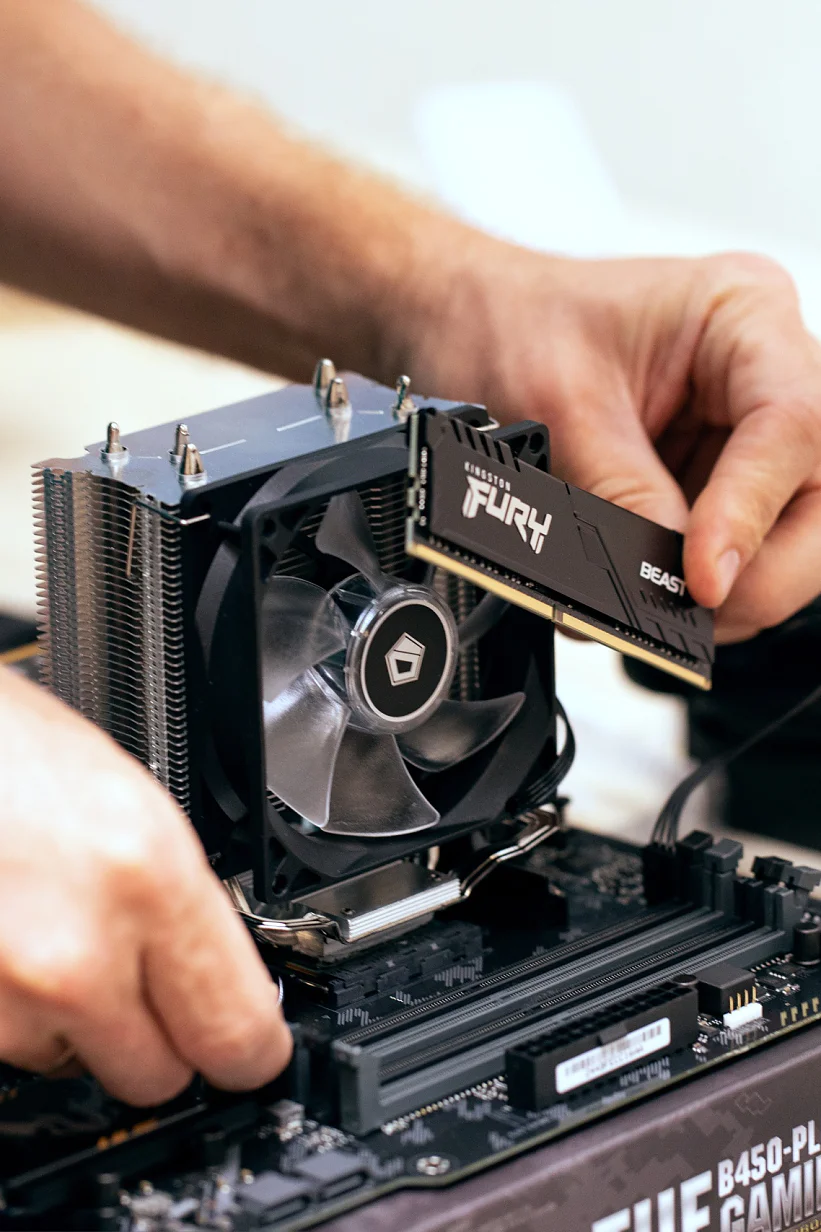

In our modern, technologically advanced world, thermal conductivity is crucial for manufacturers across the globe – driven by the rising demand for miniaturization and automation of electronic devices and products across all industries. As electronics become smaller, components are crowded into ever-smaller spaces, leading to higher heat generation and potential component damage.

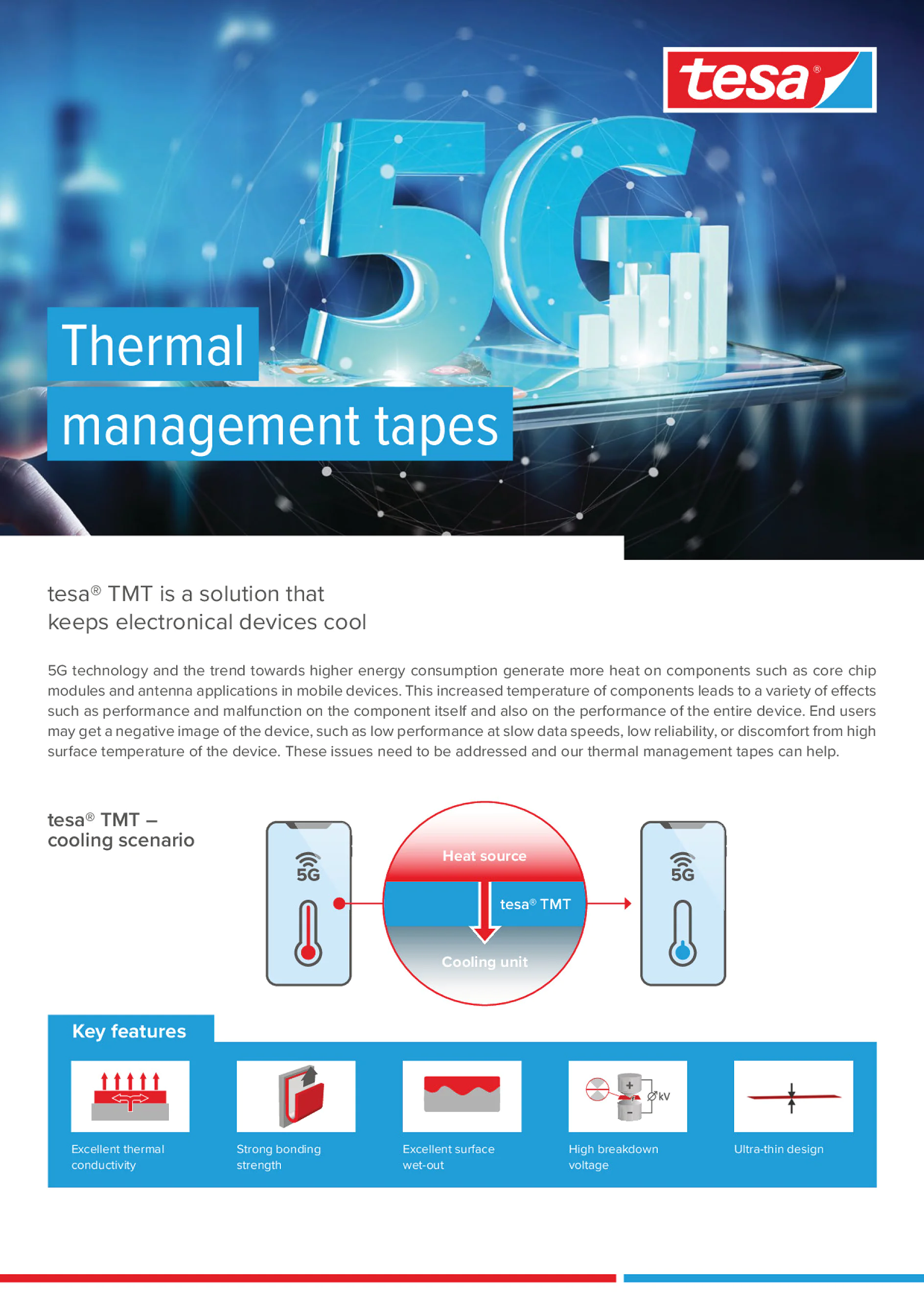

Manufacturers are increasingly looking for effective, cost-efficient heat dissipation solutions to maintain longevity, safety, and reliability. Our range of thermal tapes and thermally conductive adhesives are specifically designed to create a consistent heat transfer path between heat sources and heat sinks, for optimal thermal management. They are popular with manufacturers because they save weight and space and are quick and easy to apply in production.

Heat dissipation solutions that are tested and approved

Our thermal insulation tapes provide optimal resistance to heat, effectively preventing heat transfer in industrial applications. Featuring an acrylic-based adhesive with comprehensive insulation properties, they are available in various thicknesses and thermal conductivities. All our halogen-free tapes exhibit good flame retardancy and excellent bonding reliability, even under extreme conditions.

At tesa, we rigorously test our thermal tapes to ensure they meet the highest standards of quality and performance. Using state-of-the-art testing facilities and equipment, we simulate real-life conditions and scenarios. We test and evaluate against international norms and guidelines such as IEC, UL, and ISO. Additionally, our tapes are REACH and RoHS compliant. From melting points and glass transition temperatures to thermal conductivity and expansion, we are constantly developing and improving the stability and resistance of our thermally conductive adhesives and tapes.

No sweat – easily discover the right thermal tape with our product finder

Elevated adhesive strength and thermal conductivity, extremely thin and smooth adhesive layers, and simple and clean application make our thermal tapes the go-to choice. Our range of thermal tapes, thermally conductive adhesives, and heat dissipation solutions is designed to meet diverse industry demands.

Explore our comprehensive selection with the online product finder, which allows you to find the best thermal interface materials for your specific application. Whether you need high-performance thermal tapes for automotive, electronics, or industrial applications, our product finder simplifies the selection process.

Practical industrial applications for our thermal tapes

Thermal insulation tapes support energy efficiency in several sectors. By minimizing heat loss and avoiding temperature fluctuations, our heat transfer tapes contribute to meeting business efficiency goals.

In the automotive industry, our thermal tapes are used in engine compartments to ensure wiring, hoses, and other components do not overheat. They are also used in electric vehicles to secure battery modules and act as thermal interface materials (TIMs) for managing heat dissipation. Smartphone and tablet manufacturers use our thermal tapes to protect internal components such as chip modules and antennas from high operating temperatures. Keeping the device cool prevents components from malfunctioning, which could lead to slow data speeds and unreliable performance.

Our assortment of aluminum foil tapes has been developed to meet the most rigorous demands of the HVAC (heating, ventilation, and air conditioning) industry. Offering high durability and thermal resistance, these thermal tapes are suitable for interior and exterior applications, including insulating pipes, ductwork, and windows.

FAQs about thermal tapes

What are the key considerations when selecting thermal tapes for specific applications?

There are several factors to consider when choosing a thermal tape for a specific industrial application. Firstly, select thermal tapes with high thermal conductivity to efficiently transfer heat away from vital components. Ensure the thermally conductive adhesive used remains effective at high temperatures and does not degrade or lose bonding strength. Establish if the tape is durable enough to stand constant exposure to heat, or how it performs if the heat fluctuates or is intermittent. Lastly, verify that the thermal tapes meet relevant industry standards and certifications for your specific application.

How do thermal tapes compare to other heat management solutions in industrial settings?

Thermal tapes are widely used for heat management solutions in industrial settings due to their ease of application and cost-effectiveness. They maintain their properties at high temperatures and provide even heat distribution, offering long-term performance with minimal degradation over time. Thermal greases and pastes effectively fill microscopic air gaps but can be messy to apply and may require reapplication as they dry out. Thermal gels, on the other hand, are more resilient and less likely to dry out compared to grease but are typically pricier.

What's the difference between thermal conductivity and thermal impedance?

The terms thermal conductivity and thermal impedance are often used when discussing heat management in materials, but they refer to different properties. Thermal conductivity means a material's ability to conduct heat, measuring how efficiently heat travels through the material. High thermal conductivity is essential for materials used to transfer heat away from electronic components to prevent overheating. Thermal impedance, on the other hand, refers to the resistance to heat flow across an interface or material, typically considering the combined effect of thermal conductivity and the thickness of the material. Low impedance indicates that the thermal interface or material allows heat to flow through it easily, allowing for effective heat dissipation. Thermal impedance is a critical factor in applications where heat must be transferred across interfaces, such as between a heat sink and an electronic component.