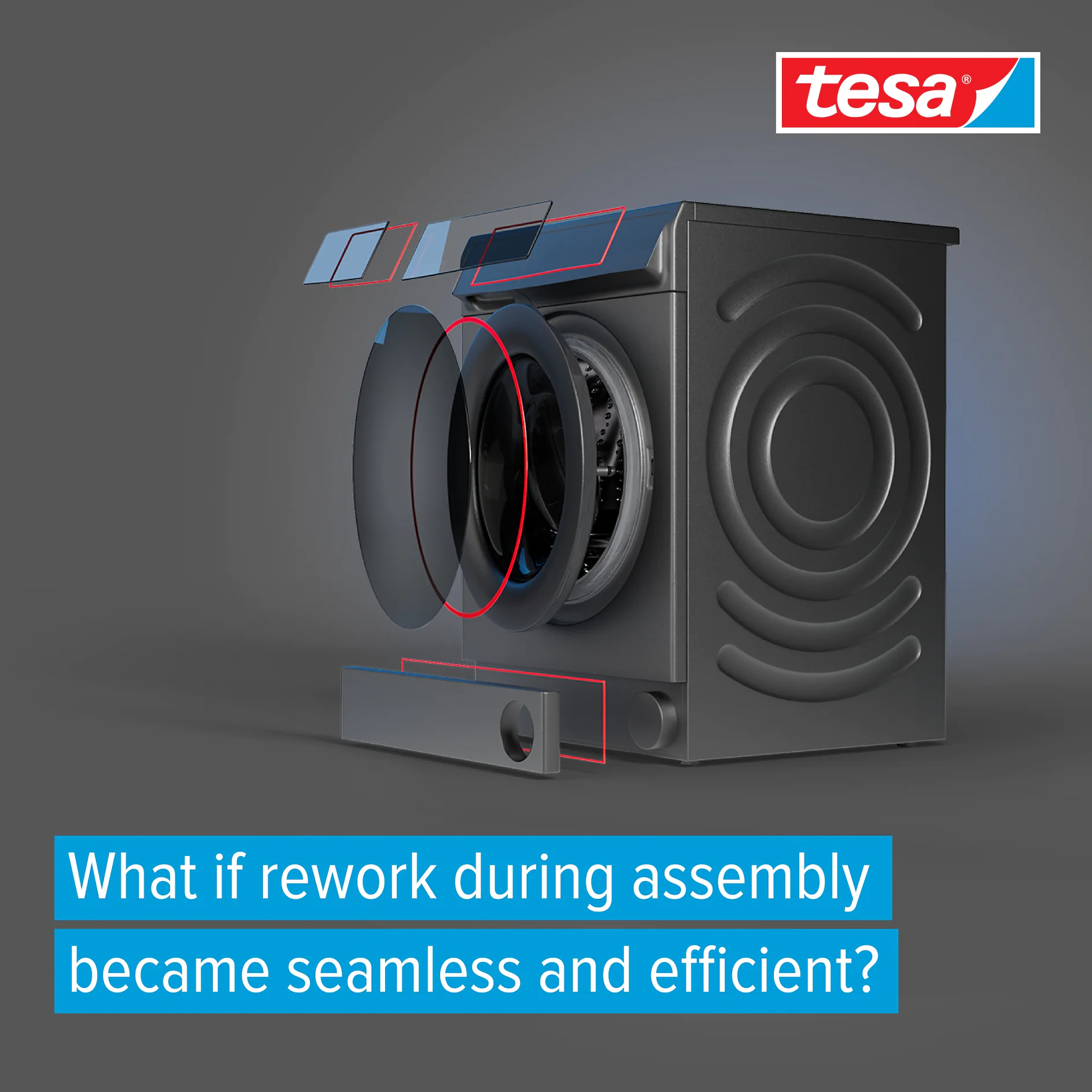

01Separation by design

Designing for separation is a smarter, more future-ready approach. Our innovative adhesive technologies can empower engineers and designers to rethink the entire product lifecycle from assembly to end of life, enhancing both design flexibility and circularity.