tesa® 4576 PV0

Venting tape

Product description

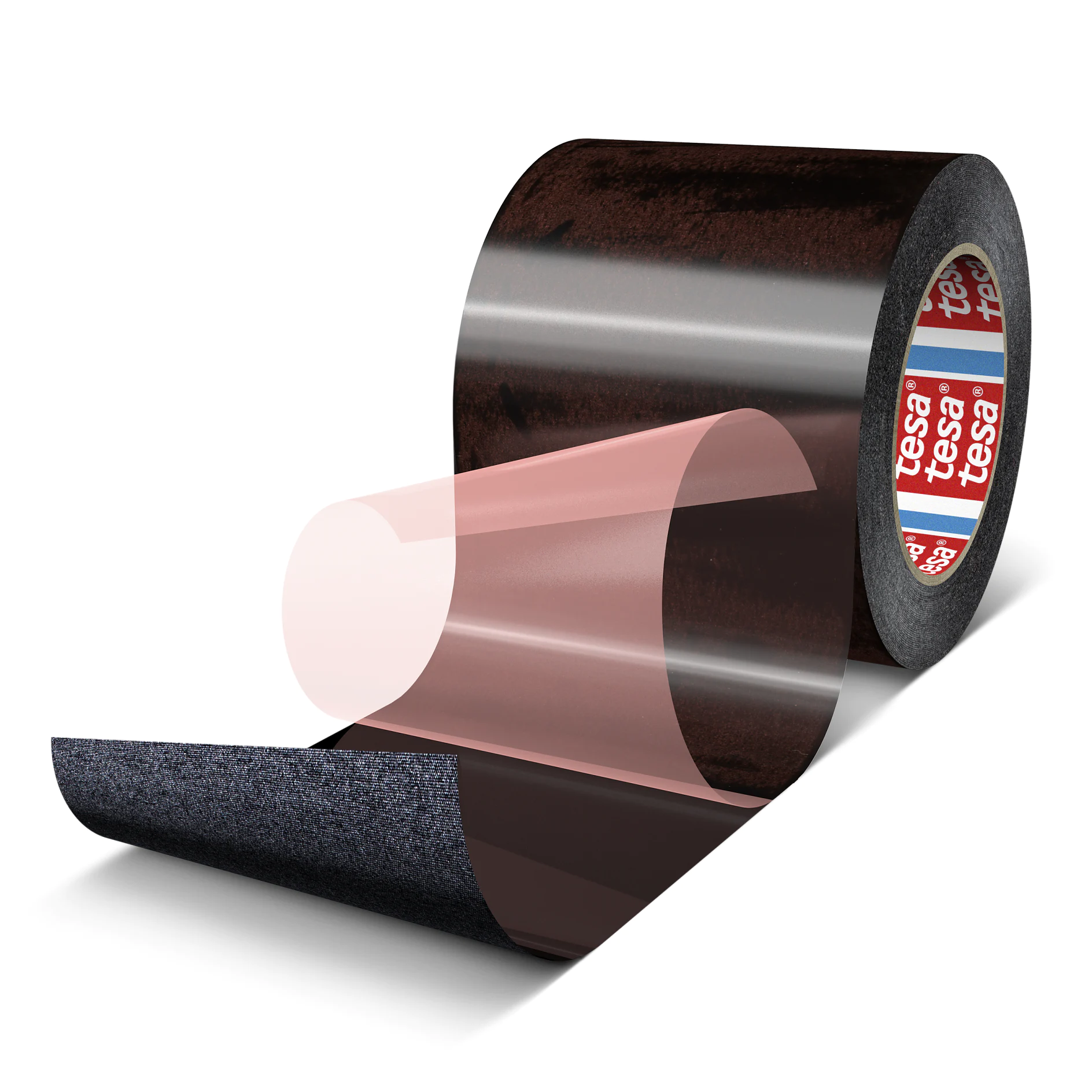

tesa® 4576 is a single-sided tape for venting applications. It is based on a nonwoven fabric coated with acrylic adhesive. The selected backing ensures conformability and gives certain air permeability. It is an ideal barrier for your foaming processes.

Features:

- The excellent barrier against foam leakage makes this tape a best seller in the market

- A certain air permeability allows the foam to expand while the tape will cover venting holes

- Is highly conformable to shaped structures

- Unwinds gently to avoid curling which makes the handling easier in order to reduce process time

- Easily torn by hand for an increased working efficiency

- Ageing-resistant design

- Certification according to UL 94 HB flame rating

Product details and specifications

Application Fields

The venting tape is used to cover holes during foaming processes in different industries

- Designed for appliances where the foam is used to insulate fridges and freezers, as well as to stabilize the body

- In production of special vehicles such as refrigerator trucks

Product Construction

| Adhesive Type | acrylic |

|---|---|

| Backing material | non-woven |

| Color | white |

| Total thickness |

5.51 mils

140 µm |

Product Construction

| Adhesive Type | acrylic |

|---|---|

| Backing material | non-woven |

| Color | white |

| Total thickness |

5.51 mils

140 µm |

Properties / Performance Values

| Elongation at break | 17 % |

|---|---|

| Tensile strength |

5.71 lbs/in

10 N/cm |

| Hand tearability | good |

| Air permeability | 6 cm³/cm²xs |

| Solvent free | yes |

| Operation temperature up to |

320 °F

160 °C |

| Low unwinding force | good |

| Ageing resistance (UV) | very good |

Properties / Performance Values

| Elongation at break | 17 % |

|---|---|

| Tensile strength |

5.71 lbs/in

10 N/cm |

| Hand tearability | good |

| Air permeability | 6 cm³/cm²xs |

| Solvent free | yes |

| Operation temperature up to |

320 °F

160 °C |

| Low unwinding force | good |

| Ageing resistance (UV) | very good |

Adhesion to Values

| Adhesion to ABS (initial) |

1.26 lbs/in

2.2 N/cm |

|---|---|

| Adhesion to PE (initial) |

0.46 lbs/in

0.8 N/cm |

| Adhesion to PS (initial) |

1.14 lbs/in

2 N/cm |

| Adhesion to Steel |

0.57 lbs/in

1 N/cm |

Adhesion to Values

| Adhesion to ABS (initial) |

1.26 lbs/in

2.2 N/cm |

|---|---|

| Adhesion to PE (initial) |

0.46 lbs/in

0.8 N/cm |

| Adhesion to PS (initial) |

1.14 lbs/in

2 N/cm |

| Adhesion to Steel |

0.57 lbs/in

1 N/cm |

tesa® products prove their impressive quality day in, day out in demanding conditions and are regularly subjected to strict controls. All technical information and data above mentioned are provided to the best of our knowledge on the basis of our practical experience. They shall be considered as average values and are not appropriate for a specification. Therefore tesa SE can make no warranties, expressed or implied, including, but not limited to any implied warranty of merchantability or fitness for a particular purpose. The user is responsible for determining whether the tesa® product is fit for a particular purpose and suitable for the user’s method of application. If you are in any doubt, our technical staff will be glad to support you.

Downloads

Download the files below for more technical details and information on this product.