tesa® 8851

30µm double sided translucent non-woven tape

Product description

tesa® 8851 is an ultra thin double-sided non-woven tape, which has excellent temperature resistance property, ideal for micro-speaker dome mounting and FPC mounting applications.

tesa® 8851 is made from special tackified acrylic adhesive system and uses an ultra thin non-woven backing, which offers excellent temperature resistance up to 260°C and excellent converting performance. The temperature resistant glassine liner ensures it can be easily released after solder reflow process.

Key features of tesa® 8851:

- Ultra thin double-sided non-woven tape

- Stable holding power and peel strength after high temperature process

- High tensile strength

- Excellent die-cutting properties and very low oozing due to special backing

- High conformability for uneven surfaces

- High aging resistance

- Conformity to RoHS regulations

Product details and specifications

Application Fields

- Micro speaker dome mounting application

- FPC mounting application

- Mounting of electronics components, subjected to high temperature process

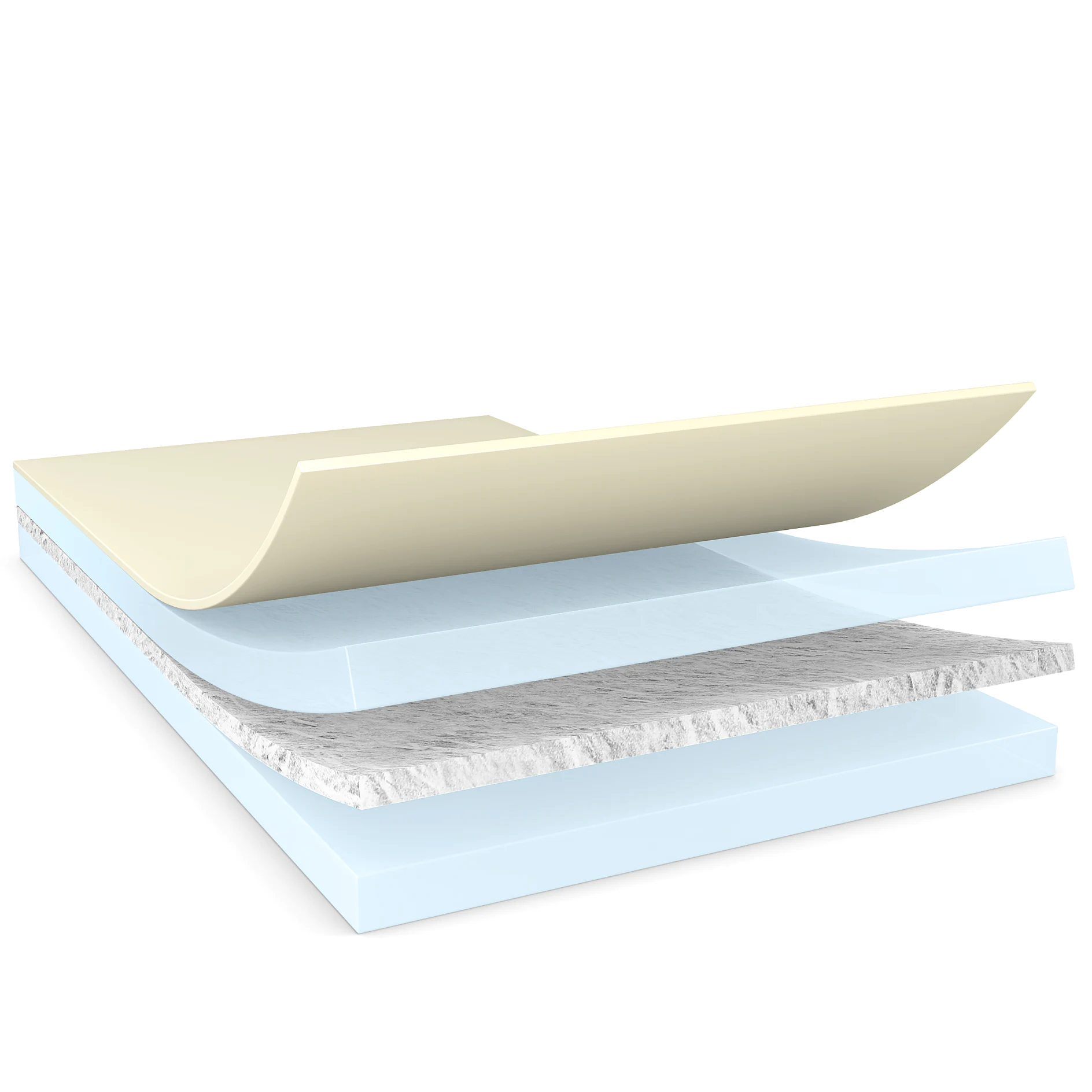

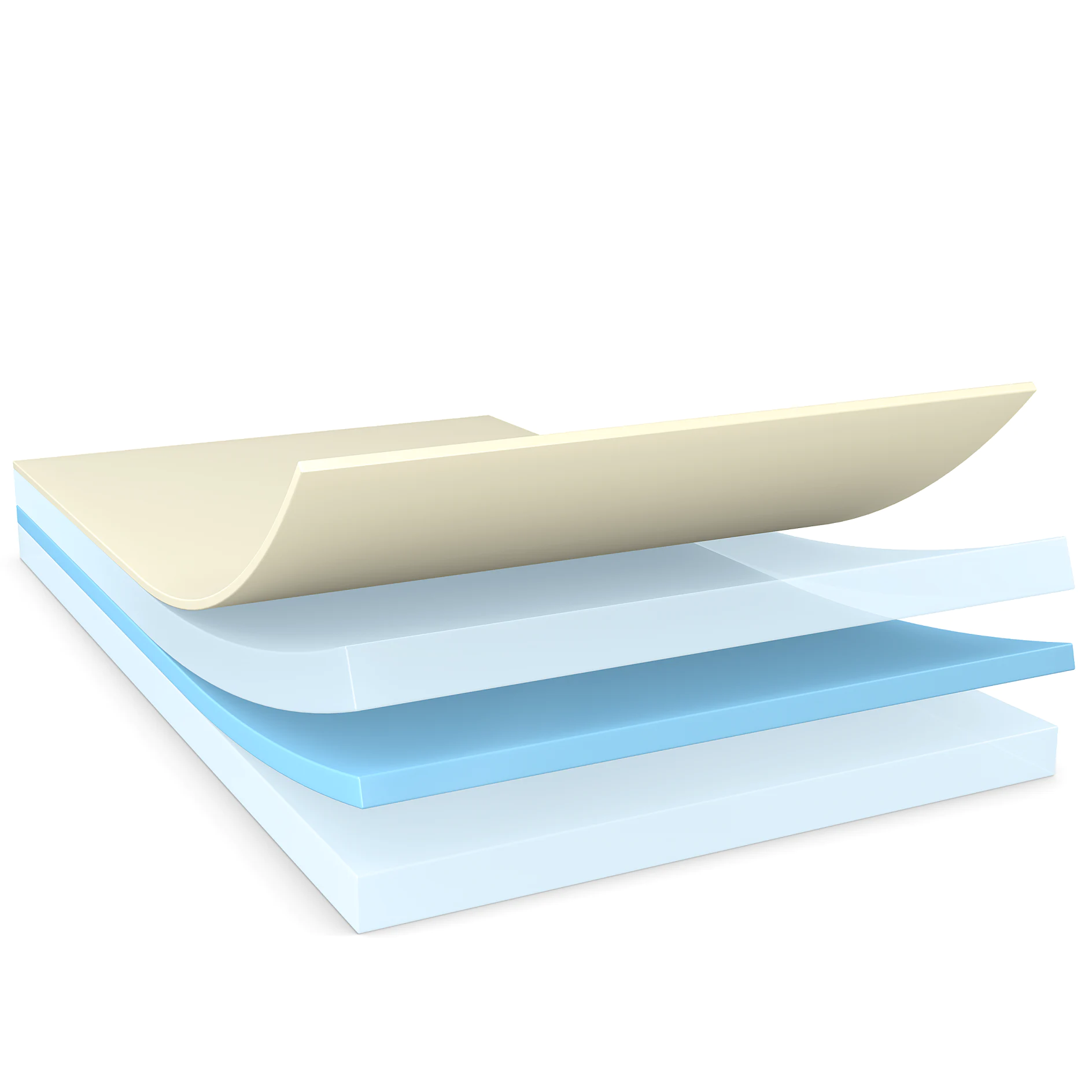

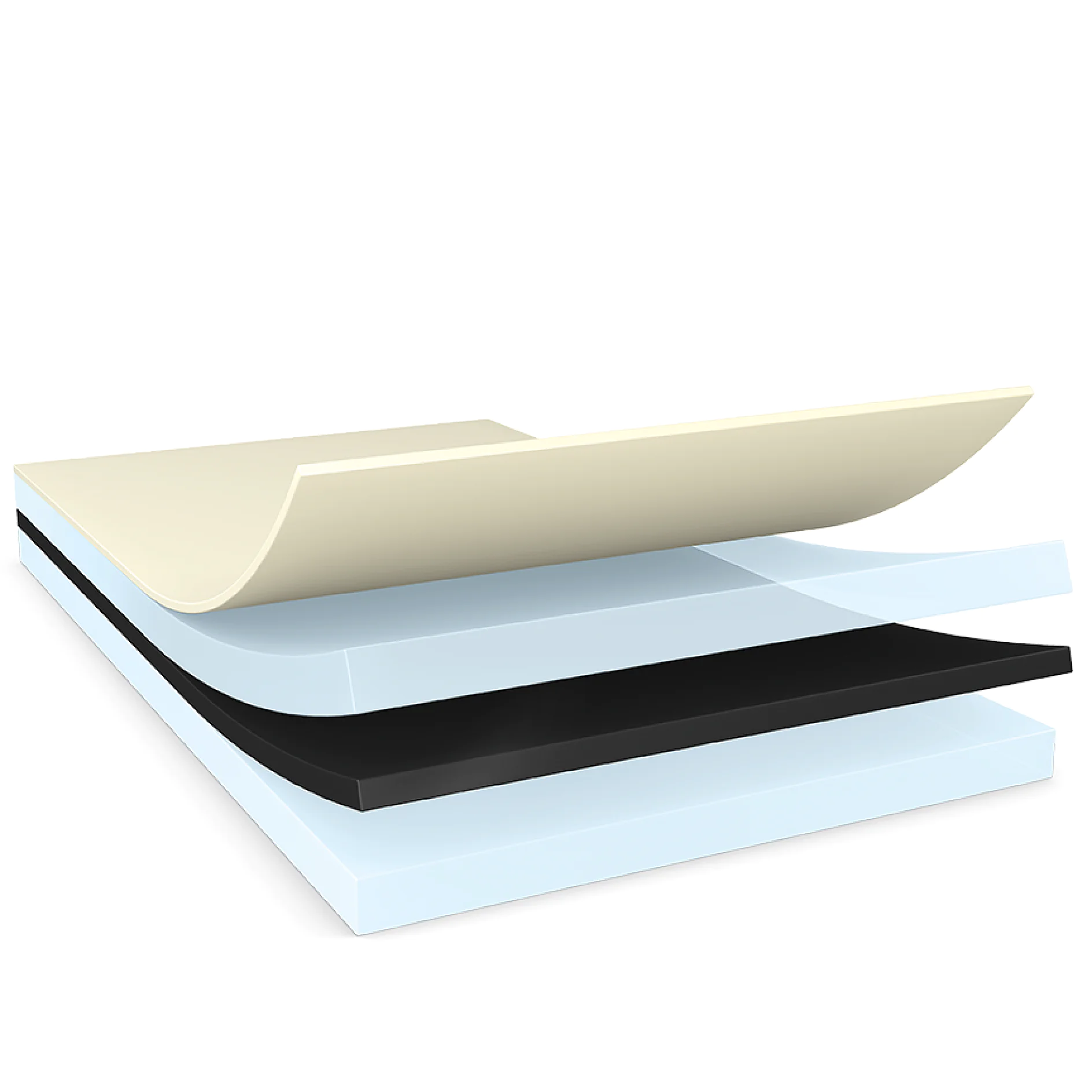

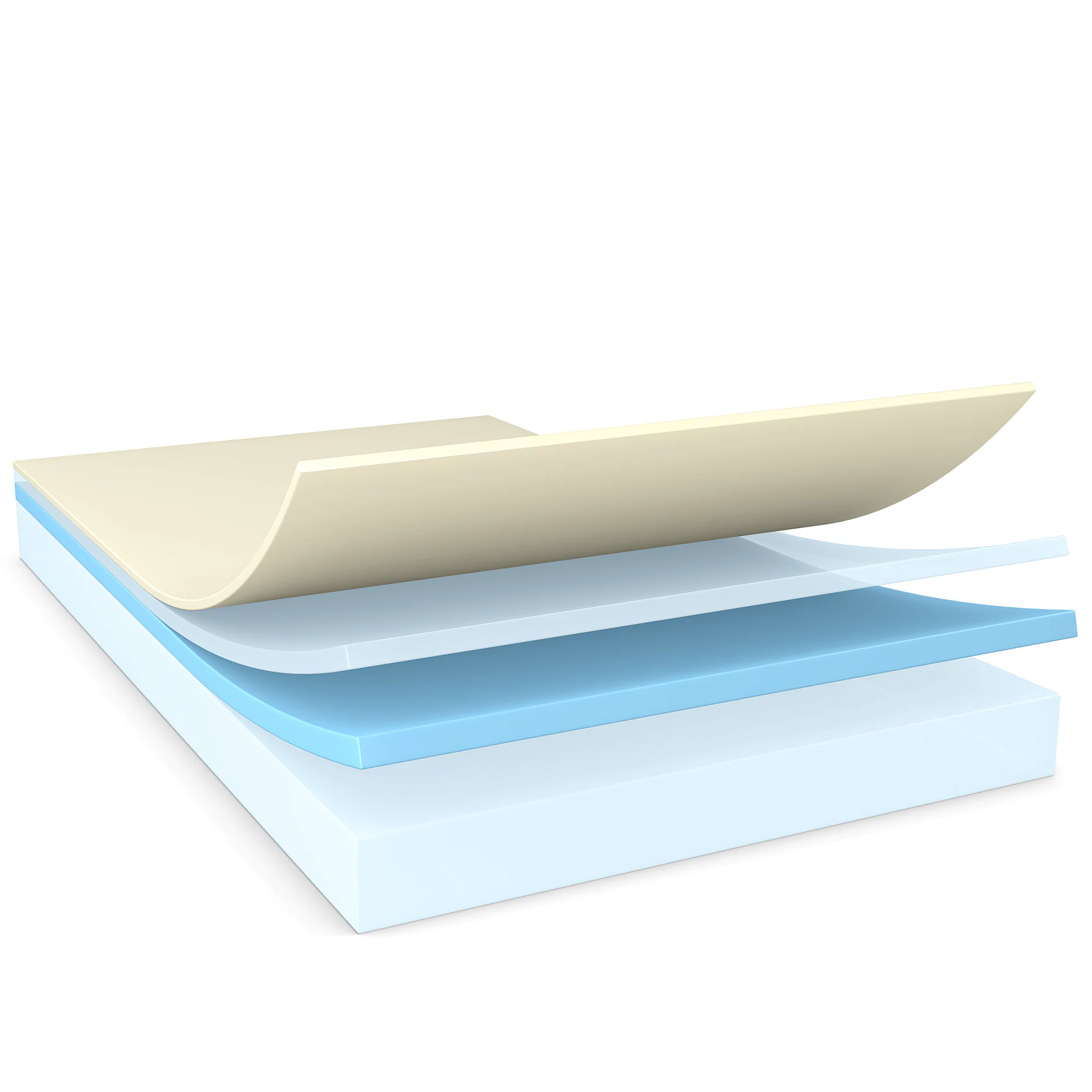

Product Construction

| Adhesive Type | tackified acrylic |

|---|---|

| Backing material | ultra thin non-woven |

| Color | translucent |

| Color of liner | white/red logo |

| Thickness of liner |

2.8 mils

71 µm |

| Total thickness |

1.18 mils

30 µm |

| Weight of liner |

116.63 lbs/in²

82 g/m² |

Product Construction

| Adhesive Type | tackified acrylic |

|---|---|

| Backing material | ultra thin non-woven |

| Color | translucent |

| Color of liner | white/red logo |

| Thickness of liner |

2.8 mils

71 µm |

| Total thickness |

1.18 mils

30 µm |

| Weight of liner |

116.63 lbs/in²

82 g/m² |

Adhesion to Values

| Adhesion to ABS (initial) |

1.94 lbs/in

3.4 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) |

2.63 lbs/in

4.6 N/cm |

| Adhesion to Aluminium (initial) |

2 lbs/in

3.5 N/cm |

| Adhesion to Aluminium (after 14 days) |

3.14 lbs/in

5.5 N/cm |

| Adhesion to PC (initial) |

2.11 lbs/in

3.7 N/cm |

| Adhesion to PC (after 14 days) |

2.86 lbs/in

5 N/cm |

| Adhesion to PET (initial) |

2.28 lbs/in

4 N/cm |

| Adhesion to PET (after 14 days) |

2.51 lbs/in

4.4 N/cm |

| Adhesion to PI (initial) |

2.46 lbs/in

4.3 N/cm |

| Adhesion to PI (after 14 days) |

2.51 lbs/in

4.4 N/cm |

| Adhesion to Steel (initial) |

2.28 lbs/in

4 N/cm |

| Adhesion to Steel (after 14 days) |

3.14 lbs/in

5.5 N/cm |

Adhesion to Values

| Adhesion to ABS (initial) |

1.94 lbs/in

3.4 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) |

2.63 lbs/in

4.6 N/cm |

| Adhesion to Aluminium (initial) |

2 lbs/in

3.5 N/cm |

| Adhesion to Aluminium (after 14 days) |

3.14 lbs/in

5.5 N/cm |

| Adhesion to PC (initial) |

2.11 lbs/in

3.7 N/cm |

| Adhesion to PC (after 14 days) |

2.86 lbs/in

5 N/cm |

| Adhesion to PET (initial) |

2.28 lbs/in

4 N/cm |

| Adhesion to PET (after 14 days) |

2.51 lbs/in

4.4 N/cm |

| Adhesion to PI (initial) |

2.46 lbs/in

4.3 N/cm |

| Adhesion to PI (after 14 days) |

2.51 lbs/in

4.4 N/cm |

| Adhesion to Steel (initial) |

2.28 lbs/in

4 N/cm |

| Adhesion to Steel (after 14 days) |

3.14 lbs/in

5.5 N/cm |

tesa® products prove their impressive quality day in, day out in demanding conditions and are regularly subjected to strict controls. All technical information and data above mentioned are provided to the best of our knowledge on the basis of our practical experience. They shall be considered as average values and are not appropriate for a specification. Therefore tesa SE can make no warranties, expressed or implied, including, but not limited to any implied warranty of merchantability or fitness for a particular purpose. The user is responsible for determining whether the tesa® product is fit for a particular purpose and suitable for the user’s method of application. If you are in any doubt, our technical staff will be glad to support you.

Downloads

Download the files below for more technical details and information on this product.