New tesa® 50625 Basic powder coating tape for general applications

Technologies

We expanded our high-quality powder-coating assortment to cover every application and customer requirement.

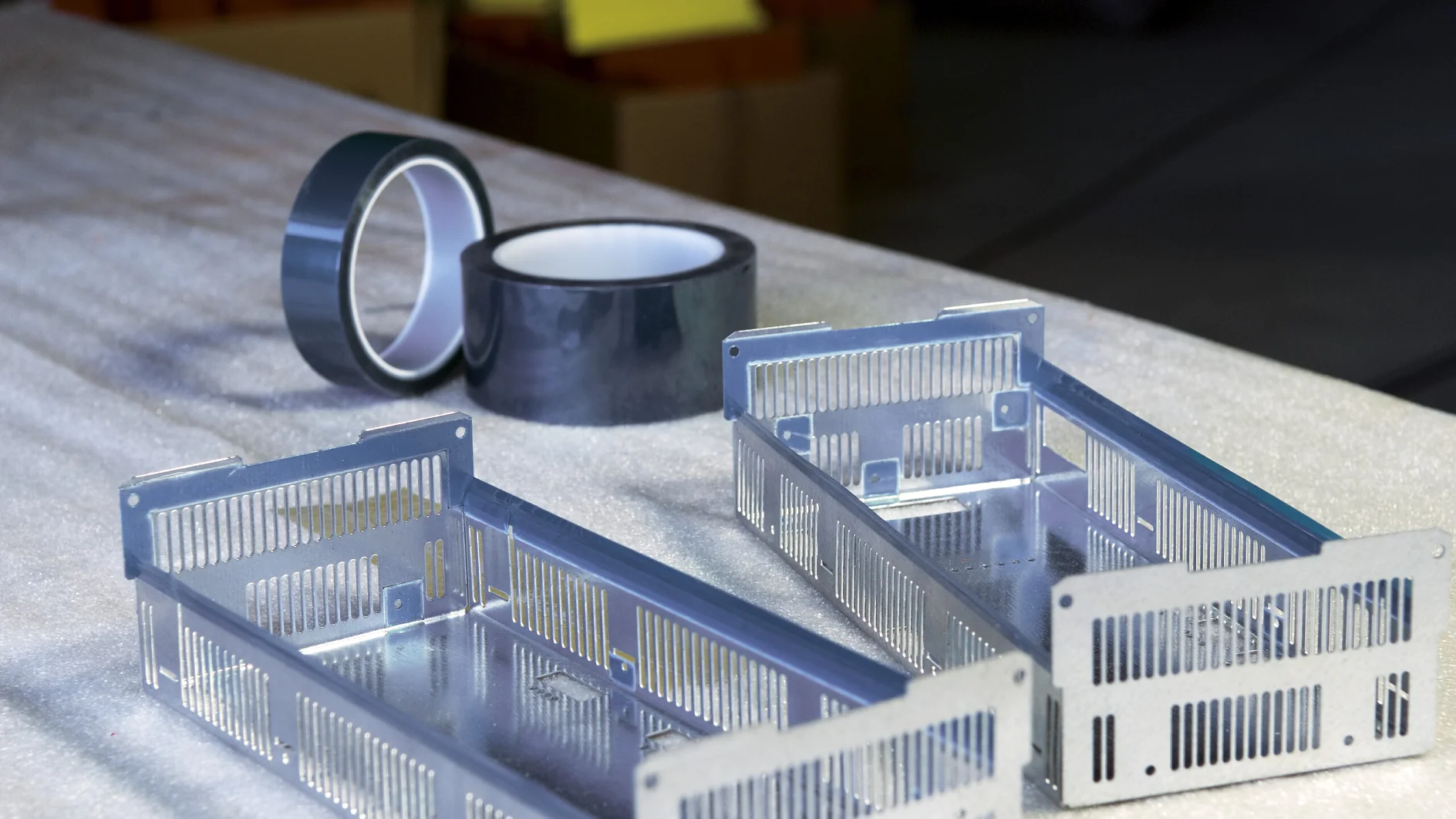

Our masking tapes are designed to withstand demanding conditions. The powder coating process involves applying dry powder electrostatically to the material and curing it by heat, resulting in a durable finish that is more robust than conventional paint. These tapes help achieve high-quality finishes by ensuring only the desired areas are coated while protecting the rest.

Key requirements for powder coating tapes

Reliable Protection: tesa masking tapes protect areas that should remain uncoated during the powder coating process. They prevent overspray and ensure clean, sharp edges.

High Temperature Resistance: Powder coating involves curing at high temperatures up to 428°F (220°C). Our masking tapes endure such heat without shrinking, curling, or leaving residue.

Additional characteristics of our masking tapes

Durability: tesa masking tapes maintain their integrity throughout the powder coating process, ensuring that the covered areas remain protected.

Clean Removal: These tapes are designed to be removed cleanly without leaving any adhesive residue.

Versatility: Our range includes tapes of various thicknesses, widths, and lengths to meet different masking requirements.

Our relaunched powder coating tape assortment

tesa® 61126 (opens in a new window or tab) is a premium polyester tape with a high-temperature-resistant silicone adhesive. Due to its high coating weight, it ensures a secure bond even on rough or irregular surfaces. Its excellent temperature resistance makes it suitable for demanding applications such as masking during powder coating, galvanizing, and autoclave bonding operations. Its bright red color provides excellent contrast for easy visibility.

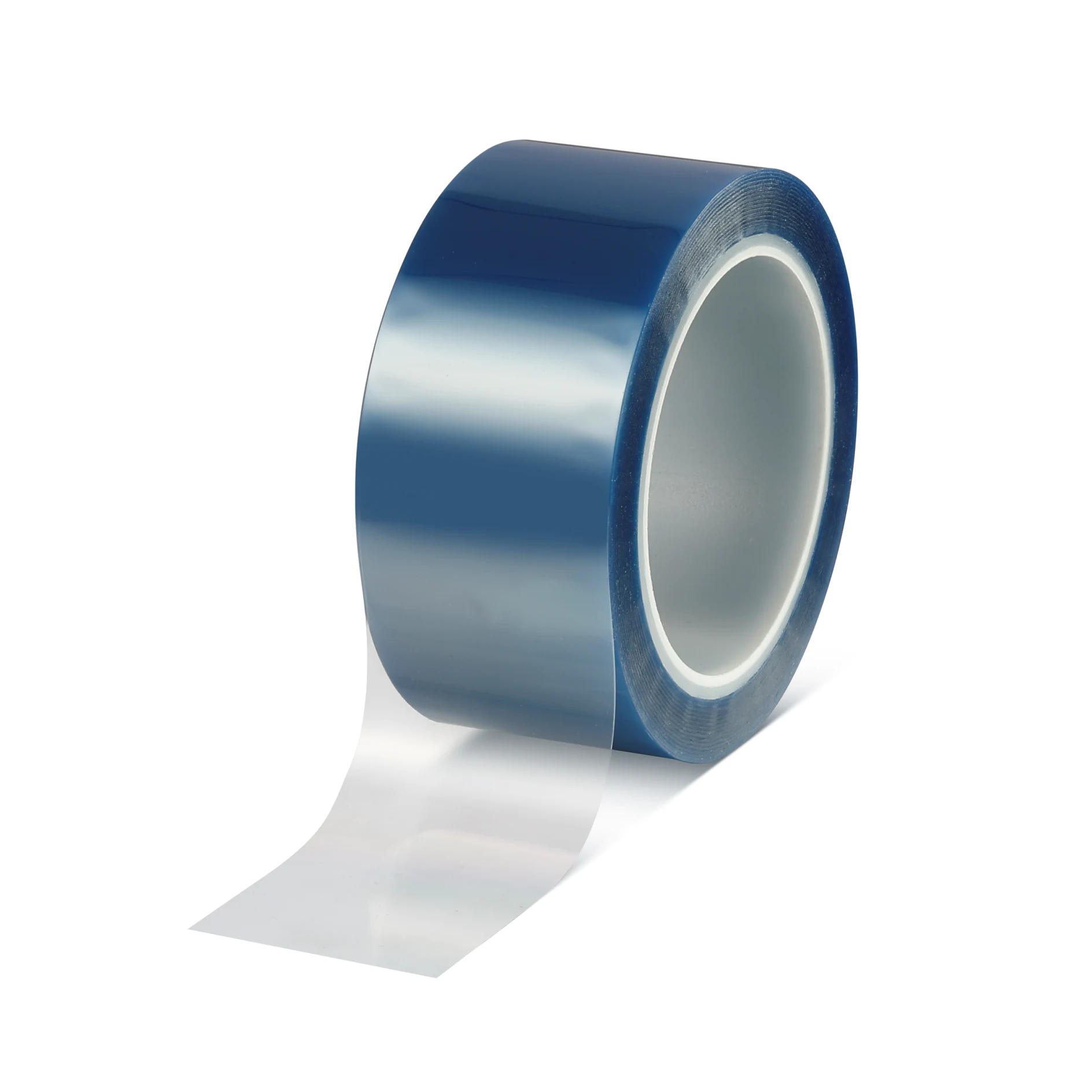

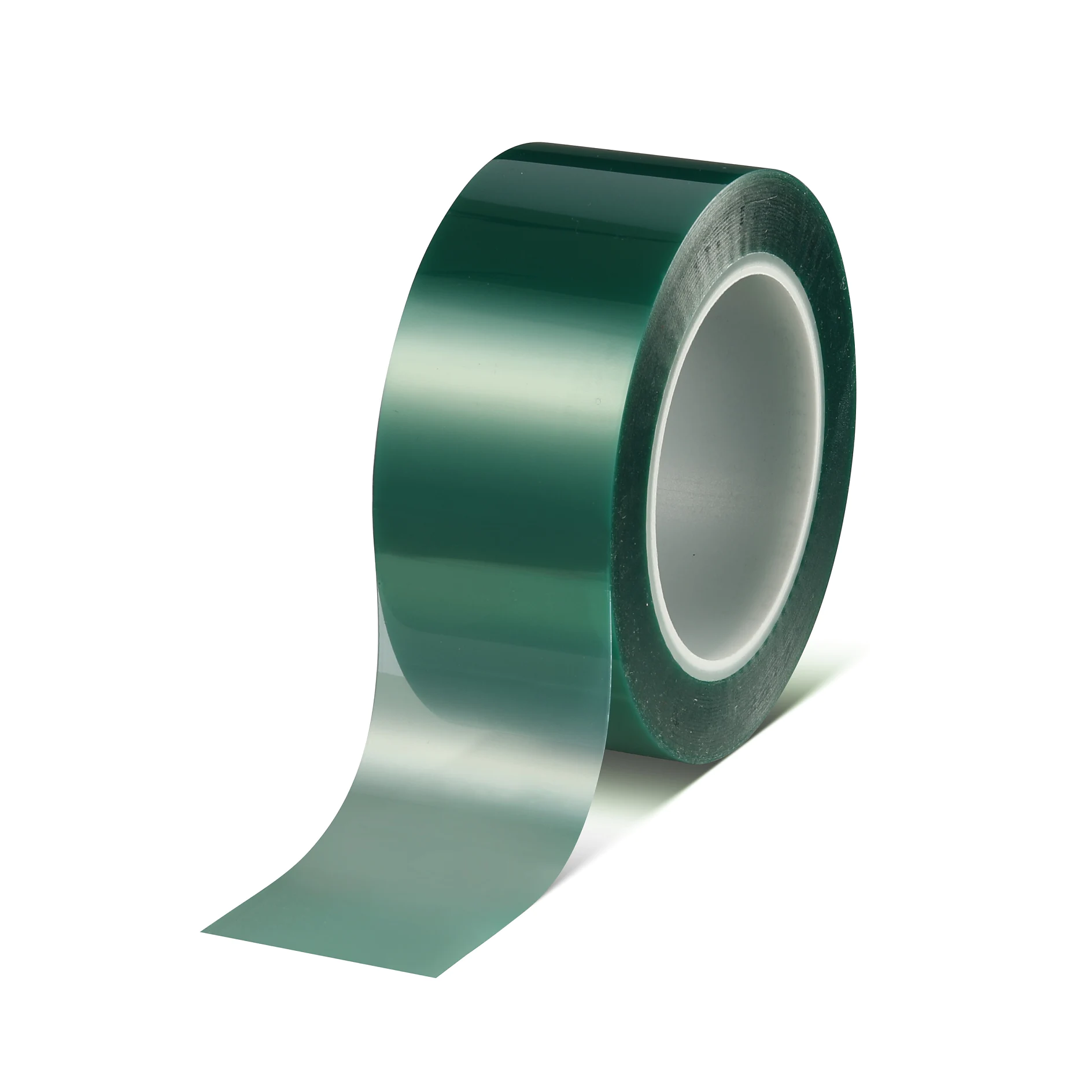

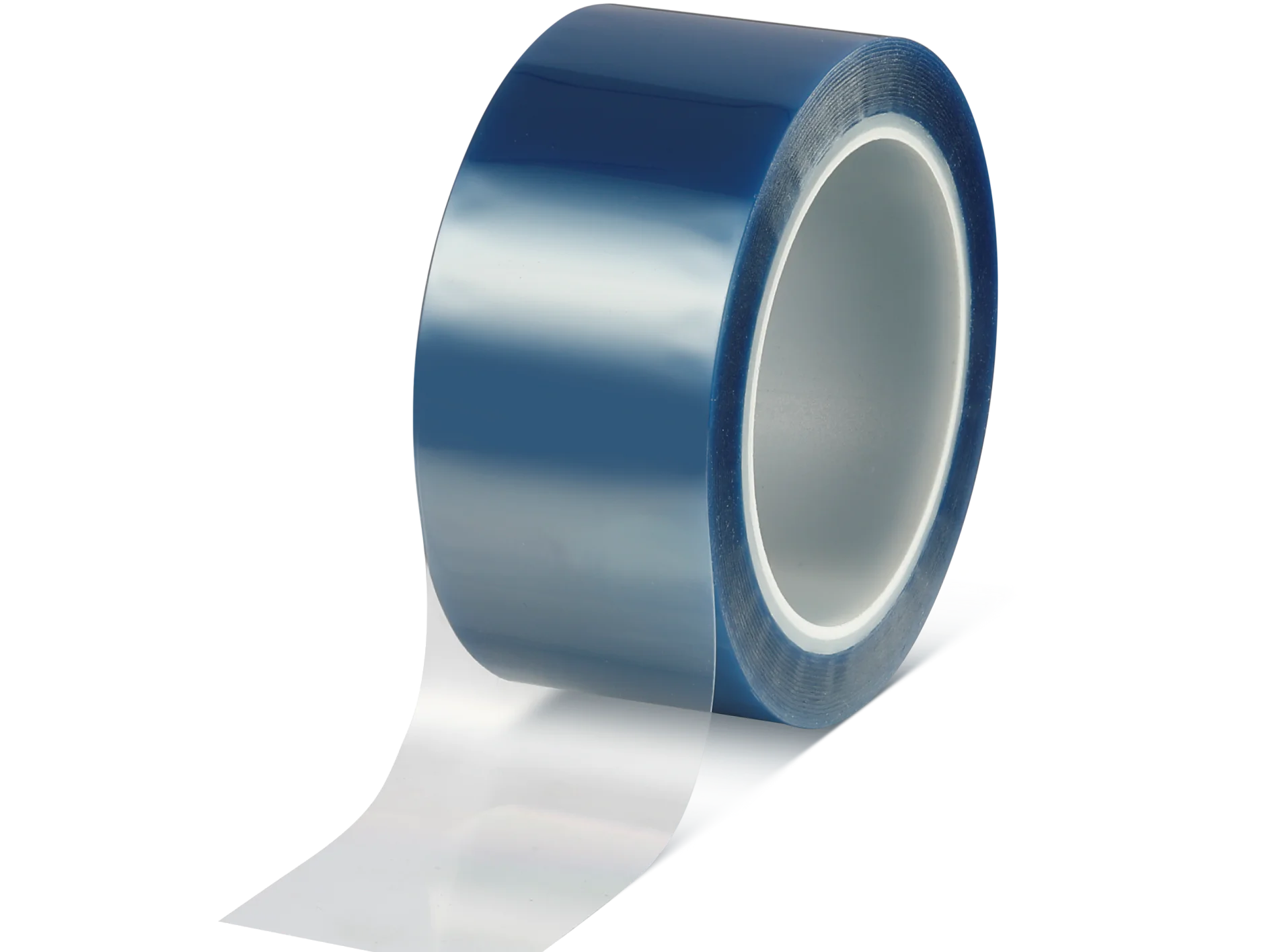

Our performance polyester range meets all diverse requirements of powder coating and withstands demanding temperatures of up to 428°F (220°C). tesa® 50650 (opens in a new window or tab) is a blue translucent tape with a total thickness of 2 mils (55 µm) and exceptional conformability. tesa® 50600 (opens in a new window or tab) has a green translucent backing with a thickness of 3 mils (80 µm) and offers high tear resistance. Both tapes have a 30 µm (1.18 mils) silicone adhesive.

Our commercial line includes green tesa® 50620, which is 2.76 mils (70 µm) thick, green translucent, resists temperatures up to 392°F (200°C), and has high tear resistance and tensile strength. Our new, thinner blue tesa® 50625 Basic powder coating tape is 1.97 mils (50 µm) thick and can withstand temperatures up to 392°F (200°C). Its flexible backing makes it suitable for irregular surfaces, providing good conformability. Like tesa® 50600 (opens in a new window or tab), tesa® 50650 (opens in a new window or tab), and tesa® 50620 (opens in a new window or tab), the bright translucent colors offer easy identification and positioning.

This versatile assortment covers every application and budget, while maintaining our commitment to quality and performance.