Reliable surface protection tape solutions

Surface protection tapes are a cost-effective way to prevent damage, reduce wear and tear, and minimize contamination during production, storage, and shipping. By protecting surfaces right up to delivery to the end consumer, manufacturers can reduce defects, reworks, and returns due to damage.

Our assortment of permanent and removable protection tapes defends against impact, moisture, temperature, abrasion, chemicals, and exposure to UV. We offer temporary protective films for interiors, weather resistant tapes for exterior use and abrasion-resistant coverings for permanent protection. Our multi-surface protective solutions safeguard painted metal and plastic bodywork, windows and glass, decorative trims and emblems, as well as carpets and upholstery from dirt and damage. And of course, our temporary protective films and tapes can be removed quickly and easily and be disposed of in an environmentally friendly way.

Use our product finder to identify the right surface protection tape or film

The number of surfaces across the applications and industries that need to be protected in the short and long term is always growing. We have brought together all our multi-surface protective solutions into a comprehensive, easy-to-use product finder. Quickly find the right removable protective tape, UV-resistant protective film, or long-lasting solution for your needs.

Temporary surface protection: A delicate balance

At tesa, developing temporary surface protection solutions is one of the most demanding adhesive challenges we face. Our surface protection solutions adhere reliably to whatever they are shielding – from household appliances, automotive panels, and LCDs to flooring, window frames, and furniture. And you can remove them easily, even after many months, without leaving any adhesive residue or causing staining and discoloration.

For larger surfaces, our films are ideal for short-term applications like painting, masking, repairs, and maintenance. They are easy to handle and apply to various surfaces. To protect floors and other surfaces, we offer safety-compliant films that provide good grip and reduce the risk of slipping.

Permanent, long-lasting protection for critical surfaces

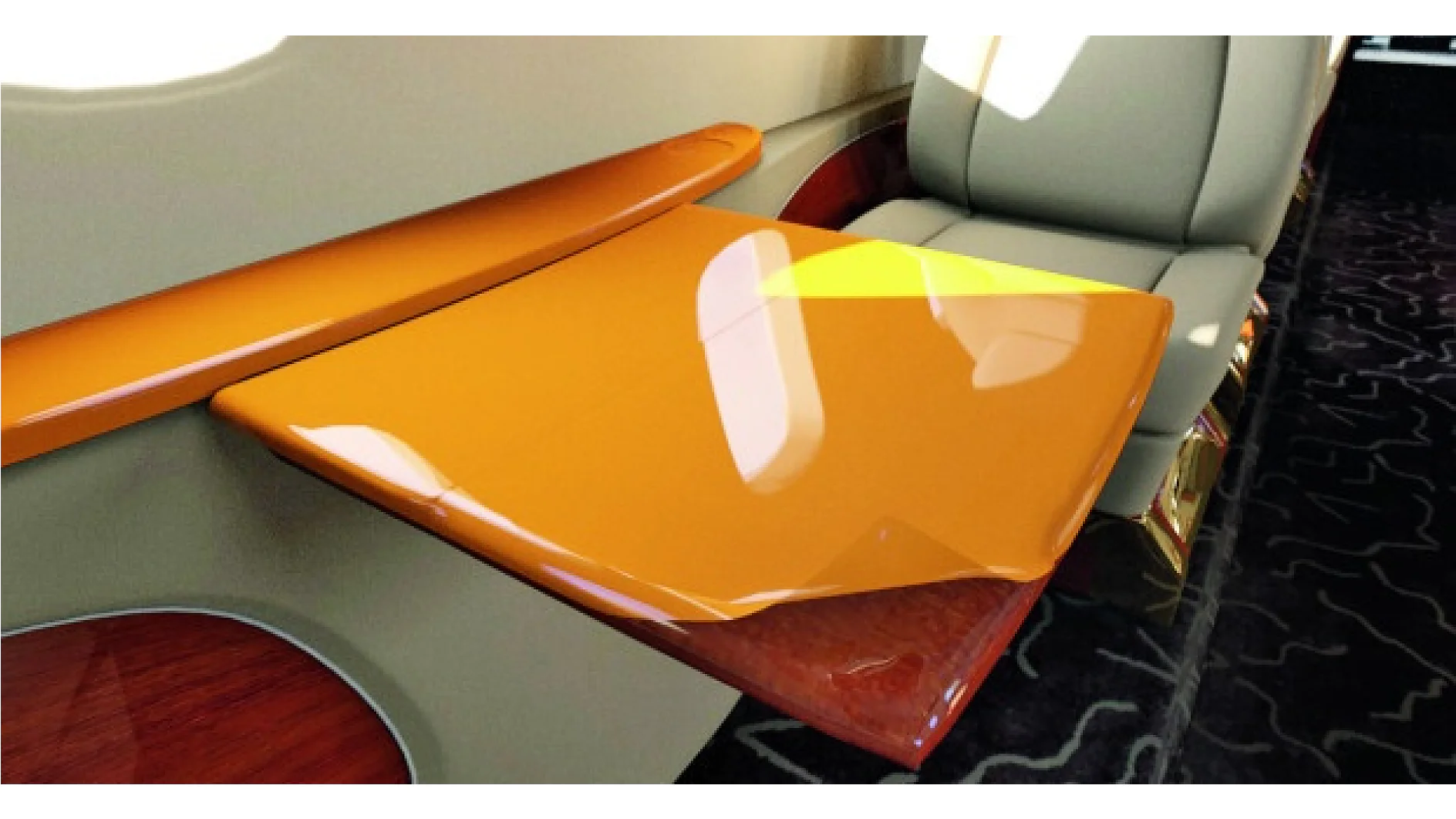

Sensitive or high-wear surfaces exposed to frequent use are best protected with our long-lasting, permanent solutions. Meeting industry’s most demanding requirements for durability, the permanent surface protection tapes in our assortment safeguard sensitive visible surfaces from external forces and mechanical damage. Additionally, our self-lubricating tapes feature gliding properties that reduce wear and friction on a multitude of surfaces – ideal for sliding parts in conveyor belts, sunroofs, copiers, drawers, and vending machines.

Our extensive range of surface protection films defends against shock and mechanical damage, widely used in the automotive industry. They are applied as a die-cut to permanently protect surfaces from abrasion, scratches, corrosion, and stone chipping.

FAQ about surface protection tapes

How do removable surface protection tapes compare to permanent protective coatings?

Removable surface protection tapes are ideal for temporary use in manufacturing, handling, storage, and installation. These tapes can be easily peeled off without leaving any residue, leaving surfaces clean. Available in various materials, they can be tailored to different surfaces and conditions, making them highly versatile for use in construction, automotive, electronics, and household appliances.

For long-term, continuous protection, especially in harsh environments, permanent scratch-resistant coatings may be more suitable. These coatings provide a durable shield against high temperatures and chemicals. However, UV-resistant protective films and tapes also offer robust protection, creating seamless, airtight bonds that repel dust, dirt, and moisture. This makes them ideal for specialized applications such as industrial equipment, outdoor structures, and high-wear areas.

Both solutions have their unique advantages and can be selected based on the specific protection requirements of the application.