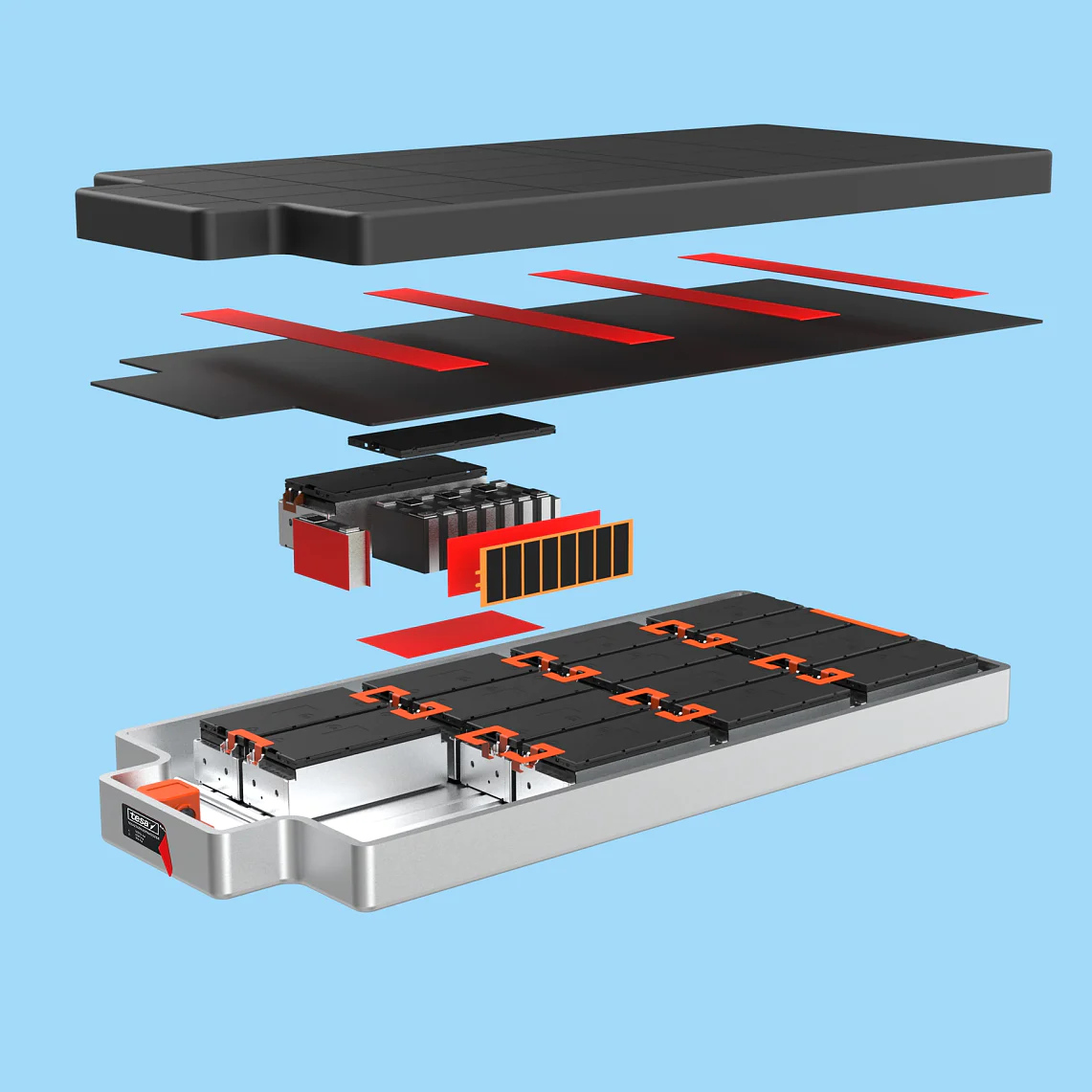

No clutch, no gearbox, no exhaust, no fuel tank: Electric cars drive with far fewer technical components than vehicles with gasoline or diesel engines. The "tank" in the electric vehicle is a high-voltage battery that supplies the electric motor with the energy it needs to run. It is often the largest component in the vehicle and is installed in the underbody, under the passenger cell. However, the battery is not a single element but consists of hundreds of components and battery cells. To manufacture these complex systems safely and in large quantities, the manufacturers rely on full automation – keyword: Industry 4.0 – also with the use of adhesive tapes. High-quality tapes offer enormous advantages thanks to their fast handling during the production process, combined with reliable adhesive and bonding properties.

Special adhesive tapes for electric vehicles

Markets

A technology is moving into the fast lane: In 2030, for the first time, more cars with electric drives than with combustion engines will be sold worldwide. Manufacturers and suppliers are working relentlessly on ever more powerful batteries – and their safe assembly. Adhesive tapes have great potential in this field: tesa specializes in the development of multifunctional tapes and, as a partner to the automotive industry, makes an important contribution to the transformation towards e-mobility.

A global topic with global structures

As one of the world's leading suppliers of adhesive tapes, tesa has been active in the field of e-mobility since 2016 – It is an area with great growth opportunities: "The switch to electromobility is a global issue. That's why our team also works globally. With our worldwide network of product and technology development, production and customer service, we support manufacturers and suppliers with innovative solutions and enable them to operate successfully in this dynamic market." explains Dr. Nils Utesch, Head of the Sino-German Project House “ePowertrain”, in which all activities related to electromobility are bundled.

"The market is extraordinarily complex and dynamic; everyone is still learning. This brings enormous technological challenges as well as fantastic business opportunities at the same time. We enable our customers in this transformation process."

International Product Manager, BU Automotive

Core business and future fields

Two major application areas represent the core business at tesa: permanent bonding of battery cells and insulation of electronic components. A recent project for a renowned battery manufacturer showed that customers can rely on our fast and efficient service: Thanks to the international cooperation among tesa colleagues in South Korea, Hungary, China, and Germany, it was possible to adapt adhesive tapes to the new specific requirements of the customer at short notice and to enable the production start. The example also shows how fast the innovation pace is when it comes to electromobility. In the short to medium term, the industry will call for tapes that improve the cooling of batteries.

The advantage for tesa: When developing new solutions, the expert teams can rely on proven products, as Dr. Aylin Meß, Laboratory Manager E-Mobility, explains: "We already supply thermally conductive tapes for smartphones. However, since adhesive tapes in electric cars are thicker – for example, to compensate for gaps or unevenness – their thermal resistance is also higher. We therefore have to improve the properties of the adhesive tapes, for example, by filling them with thermally conductive particles. Our extrusion technology, which is unique in this form, is perfect for this purpose – the first prototypes have already been successfully tested in the laboratory. Now, industrial-scale production begins."

Top trend: Fireproof tapes

Another important trend is the simplification of the battery structure with so-called cell-to-pack designs. From a structural point of view, this field also requires ever more thermally conductive bonds. A practical advantage: Previously, the battery cells were bundled into modules and then into battery packs – In the future, the elements belonging to the main battery could be fixed directly in a frame. "This eliminates many bonding processes and there is less mechanical strain," says Aylin Meß.

Industry experts are positive: Adhesive tapes will play their role as 'all-rounders' perfectly, especially in the field of electromobility. In the future, the requirements of the industry will increase even further, and the development cycles will become shorter. These are opportunities that tesa knows how to take advantage of.

"We are working on adhesive tapes for the fire-proof lining of battery packs as well as on solutions to completely prevent a thermal runaway by thermal insulation. This requires fire-resistant adhesive tape between the battery cells."

Senior R&D Manager

Electromobility

They don't dominate the streetscape yet, but 'electros' are steadily gaining ground compared to combustion engines. Around 7.9 million e-vehicles were registered worldwide in 2019, around 2.3 million more than in 2018. A jump of 40 percent, which, according to forecasts, could be followed by another 2.5 million newly sold electric cars in 2020. The growth is particularly strong in Europe. The continent is developing into the new 'hotspot' for electromobility, the gap to the leading market in China is narrowing. Investments – such as the US manufacturer Tesla in Germany or the Asian battery manufacturer LG Chem in Poland – show how important the European continent has become.

When it comes to assembly, insulation, and safety in battery systems, adhesive tapes play an important role. The tesa Group supports the electric vehicle industry with a wide range of products and solutions. For example, several highly functional adhesive tapes are used in a battery pack: for wire harnessing, for bonding battery cells, heat dissipation, and fire resistance as well as for sealing. Their thickness varies between 5 and 4000 micrometers (µm), the equivalent of 0.005 to 4 millimeters.