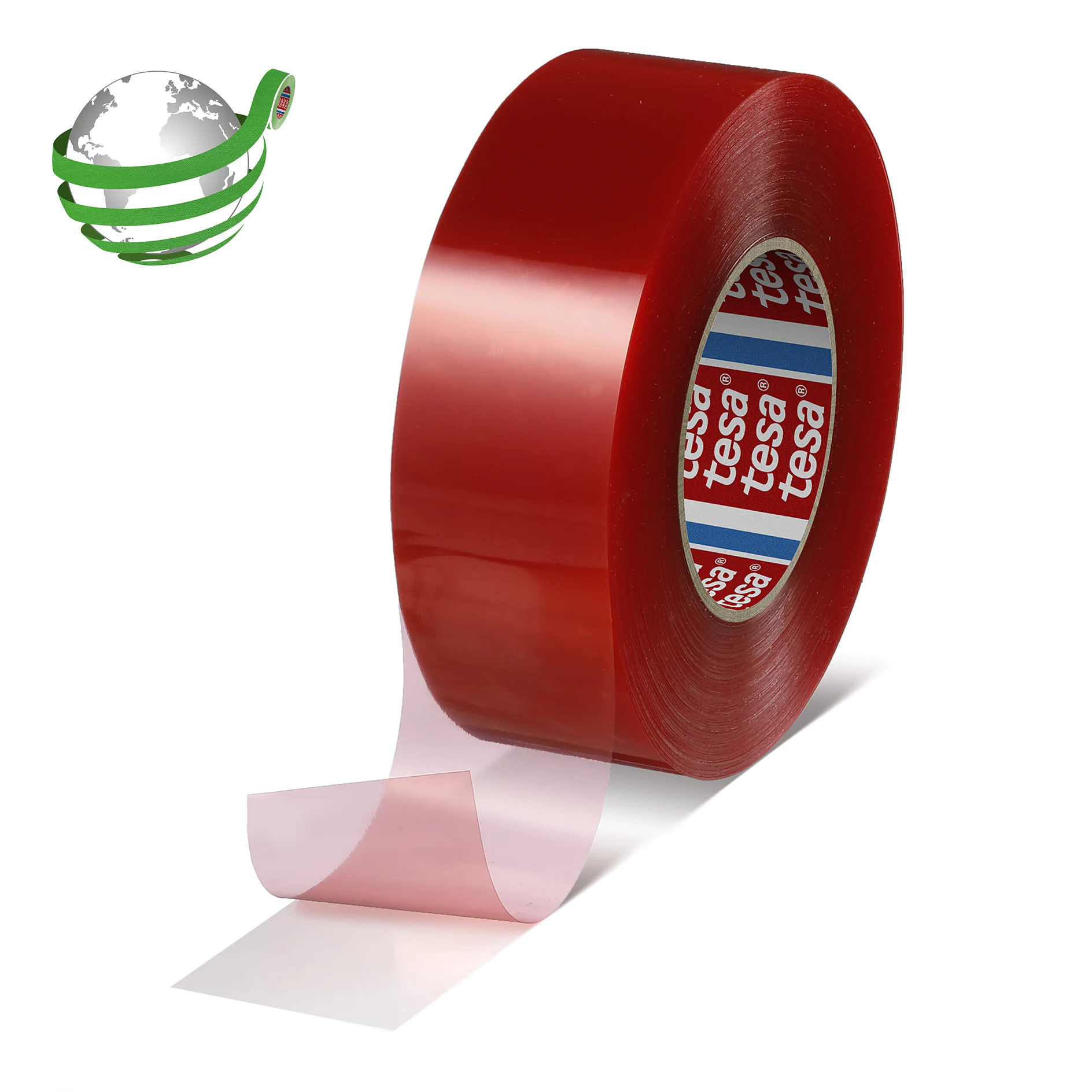

tesa® 59650 Thin

160µm / 6.3 mils double sided transparent film tape

Product Features

- High bonding strength despite thin tape design

- Immediate usability right after assembly

- Reliable bond even on low surface energy surfaces

Product description

tesa® 59650 - Team 4965 Thin is a transparent, double-sided industrial mounting tape consisting of a PET backing and a modified acrylic adhesive. The double-sided mounting tape is a thin version of tesa® 4965 Original and its adhesive is based on a patented and protected product technology. tesa® 59650 - Team 4965 Thin is used in various different industries, frequently used to bond components within electronic devices or mount decorative profiles and moldings in the furniture industry. The double-sided industrial mounting tape is able to withstand numerous environmental factors such as humidity, UV-light and temperatures of up to 200°C for limited periods of time. The tackified acrylic adhesive makes for an excellent hold on various surfaces, high tack, and good shear strength.

Several products are equipped with this unique and high performing product design and together these products make up Team 4965. This double-sided film tape assortment helps to easily select the most efficient tape based on customer demands, products, and processes. Explore the benefits of the full tesa® 4965 assortment here:

https://www.tesa.com/en-us/industry/general-applications/mounting/team-4965-assortment

Product details and specifications

Product Features

- High bonding strength despite thin tape design

- Immediate usability right after assembly

- Reliable bond even on low surface energy surfaces

- High holding power at elevated temperatures

- Good converting properties

Application Fields

- tesa® 59650 - Team 4965 Thin is used in various different industries

- Frequently used to bond components within electronic devices

- Mounting of decorative profiles and moldings in the furniture industry

- ABS plastics parts mounting for the car industry

- Mounting lenses to mobile phone housings

Product Construction

| Adhesive Type | tackified acrylic |

|---|---|

| Backing material | PET film |

| Color | transparent |

| Color of liner | red |

| Liner Type | TPP |

| Thickness of liner |

3.15 mils

80 µm |

| Total thickness |

6.3 mils

160 µm |

| Weight of liner |

102.41 lbs/in²

72 g/m² |

Product Construction

| Adhesive Type | tackified acrylic |

|---|---|

| Backing material | PET film |

| Color | transparent |

| Color of liner | red |

| Liner Type | TPP |

| Thickness of liner |

3.15 mils

80 µm |

| Total thickness |

6.3 mils

160 µm |

| Weight of liner |

102.41 lbs/in²

72 g/m² |

Properties / Performance Values

| Elongation at break | 50 % |

|---|---|

| Tensile strength |

11.42 lbs/in

20 N/cm |

| Ageing resistance (UV) | good |

| Static shear resistance at 40°C | very good |

| Chemical Resistance | good |

| Temperature resistance long term |

212 °F

100 °C |

| Tack | good |

| Static shear resistance at 23°C | very good |

| Temperature resistance min. |

-40 °F

-40 °C |

| Temperature resistance short term |

392 °F

200 °C |

| Humidity resistance | very good |

| Softener resistance | good |

Properties / Performance Values

| Elongation at break | 50 % |

|---|---|

| Tensile strength |

11.42 lbs/in

20 N/cm |

| Ageing resistance (UV) | good |

| Static shear resistance at 40°C | very good |

| Chemical Resistance | good |

| Temperature resistance long term |

212 °F

100 °C |

| Tack | good |

| Static shear resistance at 23°C | very good |

| Temperature resistance min. |

-40 °F

-40 °C |

| Temperature resistance short term |

392 °F

200 °C |

| Humidity resistance | very good |

| Softener resistance | good |

Adhesion to Values

| Adhesion to ABS (initial) |

5.6 lbs/in

9.8 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) |

6.17 lbs/in

10.8 N/cm |

| Adhesion to Aluminium (initial) |

5.48 lbs/in

9.6 N/cm |

| Adhesion to Aluminium (after 14 days) |

6.97 lbs/in

12.2 N/cm |

| Adhesion to PC (initial) |

6.68 lbs/in

11.7 N/cm |

| Adhesion to PC (after 14 days) |

7.48 lbs/in

13.1 N/cm |

| Adhesion to PE (initial) |

2.97 lbs/in

5.2 N/cm |

| Adhesion to PE (after 14 days) |

3.25 lbs/in

5.7 N/cm |

| Adhesion to PET (initial) |

5.31 lbs/in

9.3 N/cm |

| Adhesion to PET (after 14 days) |

6 lbs/in

10.5 N/cm |

| Adhesion to PP (initial) |

3.03 lbs/in

5.3 N/cm |

| Adhesion to PP (after 14 days) |

4 lbs/in

7 N/cm |

| Adhesion to PS (initial) |

5.82 lbs/in

10.2 N/cm |

| Adhesion to PS (after 14 days) |

6.34 lbs/in

11.1 N/cm |

| Adhesion to PVC (initial) |

5.08 lbs/in

8.9 N/cm |

| Adhesion to PVC (after 14 days) |

6.8 lbs/in

11.9 N/cm |

| Adhesion to Steel (initial) |

6.45 lbs/in

11.3 N/cm |

| Adhesion to Steel (after 14 days) |

7.65 lbs/in

13.4 N/cm |

Adhesion to Values

| Adhesion to ABS (initial) |

5.6 lbs/in

9.8 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) |

6.17 lbs/in

10.8 N/cm |

| Adhesion to Aluminium (initial) |

5.48 lbs/in

9.6 N/cm |

| Adhesion to Aluminium (after 14 days) |

6.97 lbs/in

12.2 N/cm |

| Adhesion to PC (initial) |

6.68 lbs/in

11.7 N/cm |

| Adhesion to PC (after 14 days) |

7.48 lbs/in

13.1 N/cm |

| Adhesion to PE (initial) |

2.97 lbs/in

5.2 N/cm |

| Adhesion to PE (after 14 days) |

3.25 lbs/in

5.7 N/cm |

| Adhesion to PET (initial) |

5.31 lbs/in

9.3 N/cm |

| Adhesion to PET (after 14 days) |

6 lbs/in

10.5 N/cm |

| Adhesion to PP (initial) |

3.03 lbs/in

5.3 N/cm |

| Adhesion to PP (after 14 days) |

4 lbs/in

7 N/cm |

| Adhesion to PS (initial) |

5.82 lbs/in

10.2 N/cm |

| Adhesion to PS (after 14 days) |

6.34 lbs/in

11.1 N/cm |

| Adhesion to PVC (initial) |

5.08 lbs/in

8.9 N/cm |

| Adhesion to PVC (after 14 days) |

6.8 lbs/in

11.9 N/cm |

| Adhesion to Steel (initial) |

6.45 lbs/in

11.3 N/cm |

| Adhesion to Steel (after 14 days) |

7.65 lbs/in

13.4 N/cm |

Download the files below for more technical details and information on this product.