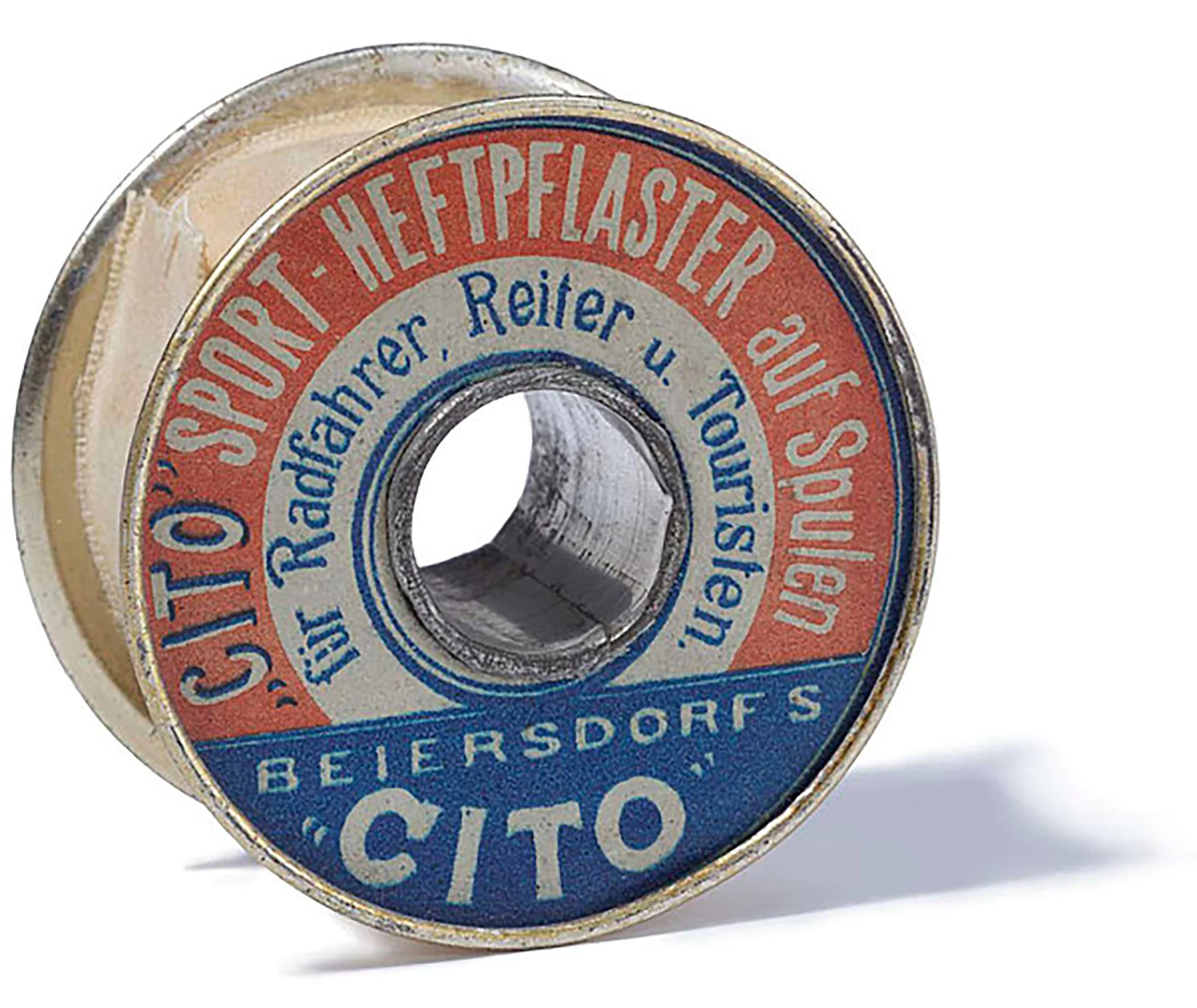

Atotal flop as a sticking plaster for the skin, but perfect for repairing bicycle tubes! Amazing inventions sometimes have to be reconceptualized to be put to good use. The world-first technical adhesive tape, which was released on the market in 1896 under the name of “Cito-Sportheftpflaster,” paved the way for tesa’s success. With tesafilm®, an adhesive tape renowned in Germany for its quality, the versatile product for home and office use was met with enormous success in the mid-1930s.

There´s This Much Tape in Progress

History

The company’s success story began with adhesive tape to repair the inner tubes of bicycles. Over 120 years later, tesa is even used on wind turbines and skyscrapers.

But tesa is much more than its classic adhesive film, and this is all thanks to Hugo Kirchberg. Starting in 1934, the enthusiastic salesman expanded the tesa® adhesive tape business systematically. To achieve his vision of “the limitless possibilities of self-adhesive technology,” “Mr. tesa” was always looking for new uses for the tape – with great success! The product portfolio consisted of over 600 products by the time he retired in 1974. His great pioneering spirit can still be felt today, since the number of adhesive tape products has increased more than tenfold! There are now over 7000 high-performance adhesive solutions for industry.

© Julian Hecker

tesafilm® and dispensers over the course of history – items from the tesa archive

© Julian Hecker

© Julian Hecker

© Julian Hecker

© Julian Hecker

© Julian Hecker

© Julian Hecker

High-Tech Adhesive Solutions

So that products can keep becoming smaller, flatter, lighter, more effective and more technologically sophisticated, tesa now provides many manufacturers and their suppliers in various industry sectors with specialized high-tech adhesive tapes. The adhesive solutions are used in the automotive and electronics sectors, just as they are used in newspaper printing, the health industry and in the construction of wind turbines.

Research for the Future

Over 500 scientists in the company’s own research laboratories in Germany, China and the U.S. are working on turning innovative ideas into new products and system solutions and on continually improving existing products. The product range is constantly growing. As a result, more and more forward-looking sectors have the opportunity to use adhesive solutions for their own needs. There are even intelligent adhesive solutions to protect branded products.

Products That Speak for Themselves

Since its foundation in 2001, the affiliate tesa scribos® has developed itself into the leading solutions provider for the digital revolution at product level, from its first invention, tesa® products as data storage to unique labeling technology and digital tools. International brands benefit as a result from customer interaction, protection from forgery and receiving valuable market data.

Success with tesa®

Sportspeople across all disciplines rely on tesa®. For example, high-jumpers make the smooth surface of their fiberglass rods easier to grip with a coarse layer of fabric tape. Ice hockey players wrap tape around their hockey sticks. Skeleton sliders tape the underside and edges of their sled to improve aerodynamics. On the ice track, the tear-proof fabric tape must endure a lot as the pilots race around tight turns at top speeds of up to 145 kilometers per hour. In the “top tier” Formula 1 races, mechanics also can’t do without tesa®. A TV broadcast showed that Lewis Hamilton’s headrest was fixed into place at a pit stop with tesa® 4651.

Passed the Earthquake Test

Extra-strong adhesive solutions are also available in the construction industry. Thanks to the high-performance adhesive tapes in the tesa® ACXplus range, it is even possible to secure individual facade components on the outside of a building. The acrylate adhesive tapes, which are manufactured in a patented process, are so good that they can withstand the most extreme weather conditions. This was proved in a simulated earthquake test at the University of Chile: In a 20-story high-rise building, not a single glass façade installed using tesa® was damaged.

High-Tech on Your Wrist

They measure blood pressure, count calorie consumption and monitor sleeping patterns: Smart wearables are mini-computers that are worn directly on the body, e.g., as fitness watches or smart glasses. tesa has developed a new generation of adhesive tapes for the booming growth market of wearables. This includes tapes that are resistant to sweat, perfume, sunscreen and soap.

"There are up to 49 adhesive points on a fitness watch. Many of these are very small, which requires a high level of precision – what we are best at."

Chief Executive Officer of tesa SE until 2019