Numerous electronic and electrical components such as processors or batteries generate heat. Thermal management is particularly important for consumer electronics, which include numerous powerful and often highly miniaturized components. It ensures the devices function reliably despite heat generation and are not damaged. Various materials and concepts with specific advantages and disadvantages are used to dissipate the heat loss.

Thermal Management in Consumer Electronics

Technologies

Dissipation of thermal energy to maintain the functionality of devices.

Why is thermal management so important in many end devices today?

Modern consumer electronics such as smartphones, tablets, smartwatches and smart home products are becoming more and more powerful with an increasing level of miniaturization of the installed components. The devices use processors with millions of semiconductor circuits, displays with high resolution and brightness, batteries with high energy density, high-performance LEDs and much more. These components produce thermal losses, which must be dissipated. Without thermal management, the components and devices overheat, which in turn risks functional stability and operational safety.

Which materials are particularly suitable for thermal management?

Materials with high thermal conductivity are used for thermal management. Thanks to good thermal conduction, the heat produced on the components can be transferred to cooling components and dissipated. Metals such as silver, gold, aluminum and copper are good thermal conductors. Due to its lower price, low weight and the fact that it is easy to process, aluminum is one of the preferred materials. As copper is more expensive than aluminum but has better thermal management properties, a material mix of aluminum and some copper is often used. If the requirements for heat dissipation are lower, material such as thermoplastics can be used.

The concepts for heat dissipation and their respective advantages and disadvantages

There is often no room in modern electronic devices for active cooling concepts such as fans. Fans cause noise and require energy. Passive concepts for heat dissipation are therefore generally used. Passive heat dissipation uses the physical principles of conduction (transferal of heat to another solid material), convection (transferal of heat to ambient air or liquids) and heat transfer through thermal radiation. The following information provides a brief overview of various concepts with their respective advantages and disadvantages.

Heat sink

Heat sinks are specially shaped components made of a good heat conductor, such as aluminum, with a large surface area. The heat is transferred from the generating component to the heat sink via an intermediate medium, such as heat-conducting paste, and from there to the ambient air via its surface. Heat transfer also takes place via thermal radiation. To optimize thermal radiation, heat sinks are often painted black. Many high-performance semiconductor chips are equipped with heat sinks.

The advantage of heat sinks is that they are cheap and easy to use. However, the more heat they have to dissipate, the larger they need to be. What's more, heat dissipation takes place in the immediate vicinity of the component. And for very compact devices with little space, this is a problem.

Heat spreader

A heat spreader is a thin sheet of a good heat conductor such as copper or aluminum, which is placed directly on semiconductor chips. It is often glued or soldered to the chips. The sheet metal has the task of distributing the heat produced on the component over as large an area as possible. This makes it easier to transfer it to a heat sink mounted on the heat spreader. What's more, the heat spreader protects the sensitive surface of the component housing of, for example, a processor from damage when mounting the heat sink.

Heat pipes

Heat pipes dissipate heat over longer distances. They separate the heat absorption and heat emission processes. These elements are sealed, thin-walled pipes made of a material with high thermal conductivity, which contain a small amount of a vaporizable liquid such as water or ammonia. By transferring heat from a heat generating component, the liquid in the heat pipe evaporates. The steam flows to the cooler end of the heat pipe and the heat is dissipated there via condensation using another cooling component such as a heat sink. The liquid then flows back and the process starts again. Compared to a heat sink mounted directly on the heat generating component, heat transport is much faster and possible over a greater distance. Special nano heat pipes with extremely small diameters are available for highly miniaturized consumer electronics. These can even be used on printed circuit boards for heat dissipation.

Conclusion

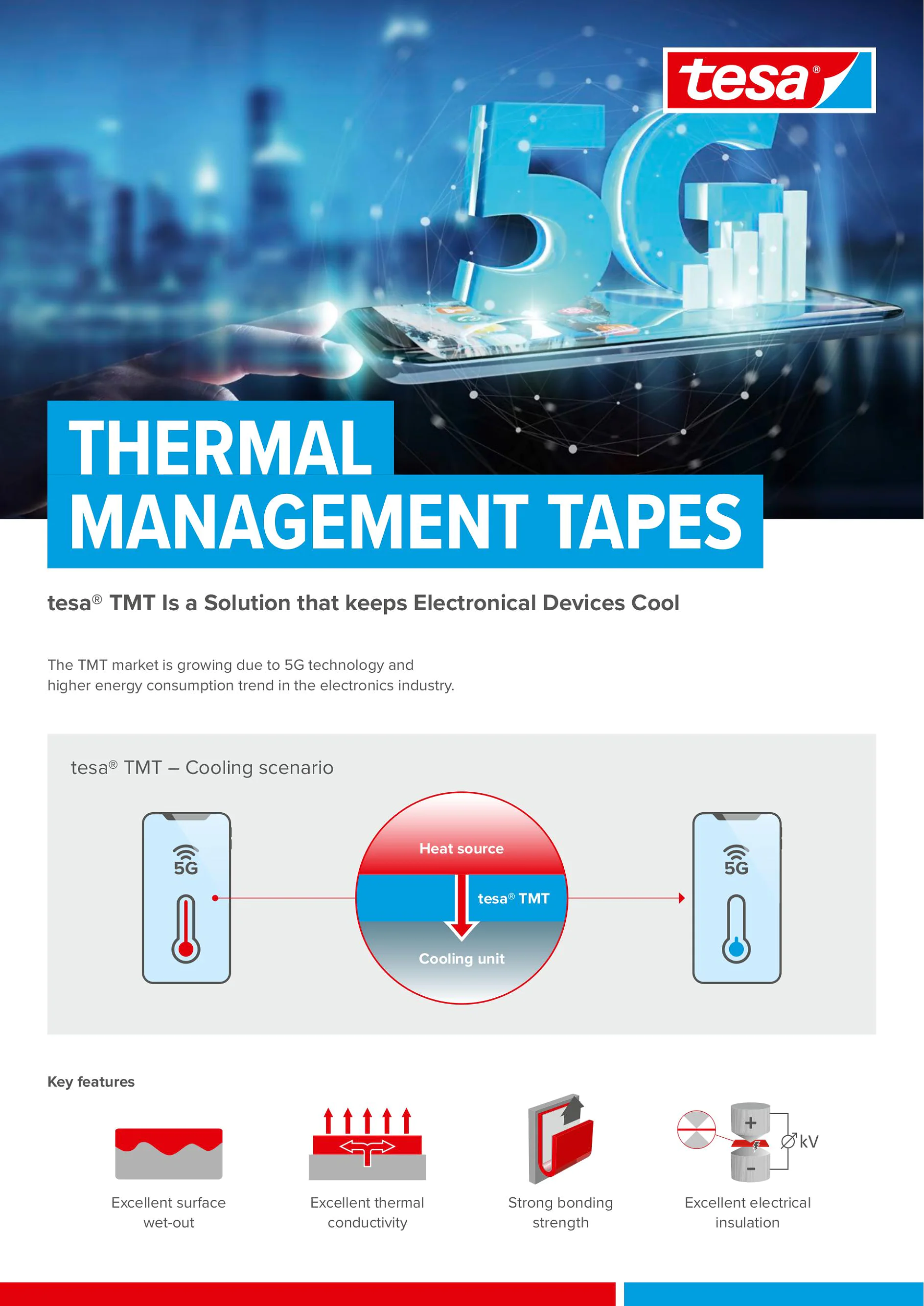

Thermal management in consumer electronics will remain important in the future. Increasingly powerful processors, displays, 5G components, and batteries generate high heat losses, which have to be dissipated in a clever way. Active cooling technologies such as fans or Peltier elements are virtually impossible to use in miniaturized devices. Because of this, passive heat dissipation via heat sinks, heat spreaders or heat pipes is the preferred technique. However, these concepts usually require additional thermal interface materials, such as thermal management tapes, to ensure optimal heat management in electronic devices.