Additional Info

Fireproofing tesa acc. VCS 7511, 17, 3.8 Fire Ingress

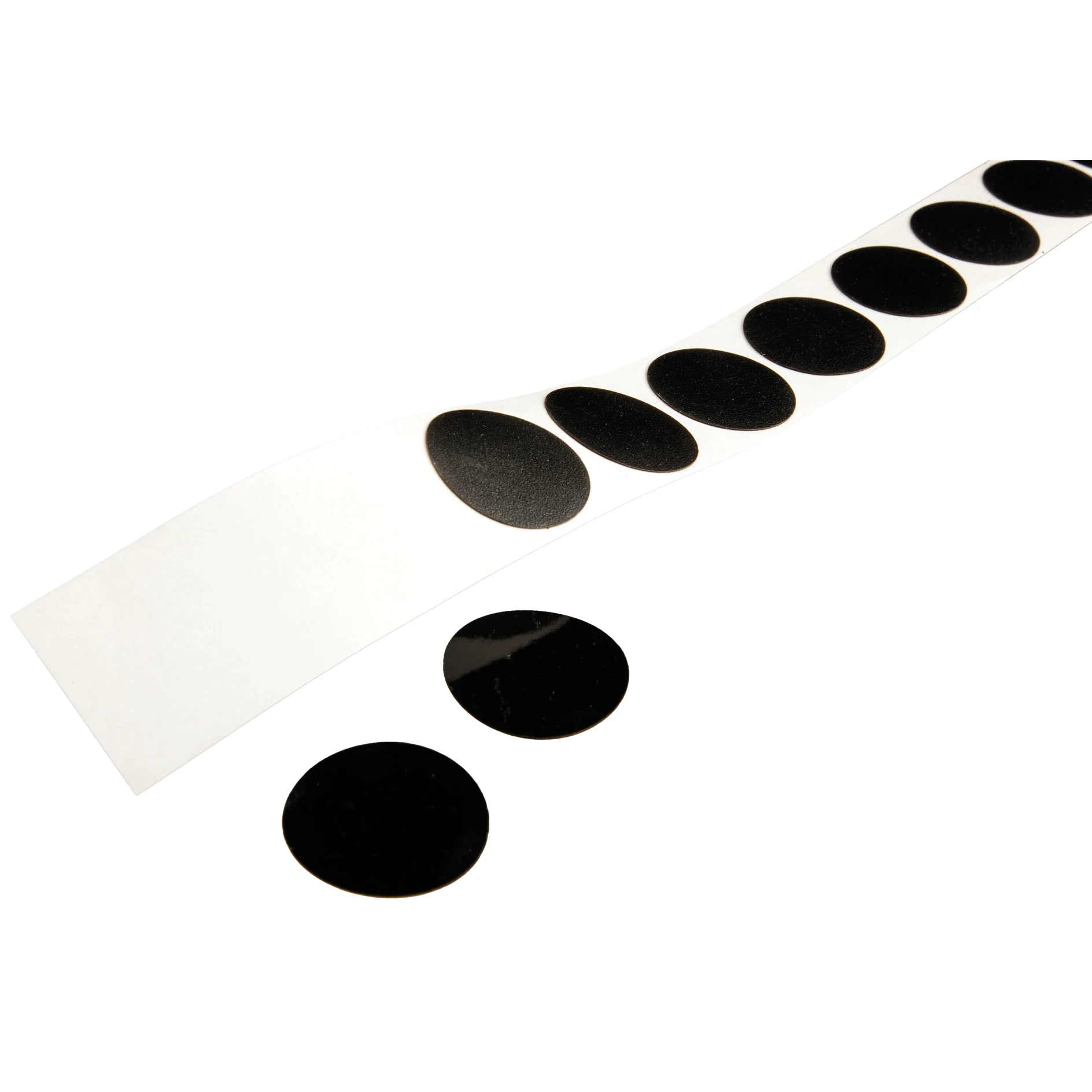

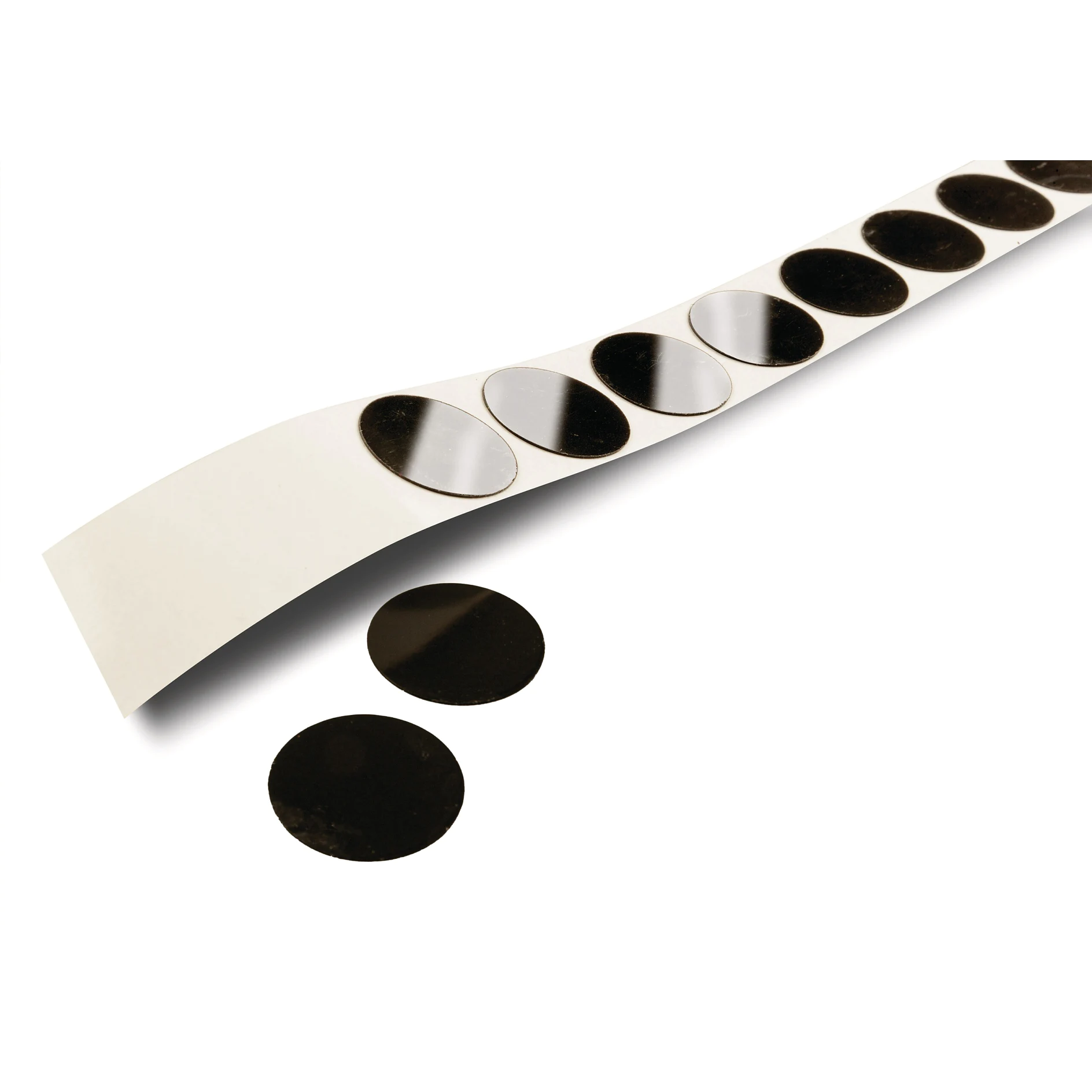

Rolls with customer specific patch dimensions can be delivered according to customer requirements and applications.

In case the product will be applied in the underbody area we are recommending an additional coverage due to low stone chip performance.

We support your individual application process with tesa designed dispensing solutions to ensure a quick and reliable sealing of holes in the car body. By fitting your robot with the best end arm tooling we enable a smart automation concept in your production site. Ask for our tesa® EfficienSeal automated dispensing tool to ensure a highly efficient and automated patch application.

Rolls with customer specific patch dimensions can be delivered according to customer requirements and applications.

In case the product will be applied in the underbody area we are recommending an additional coverage due to low stone chip performance.

We support your individual application process with tesa designed dispensing solutions to ensure a quick and reliable sealing of holes in the car body. By fitting your robot with the best end arm tooling we enable a smart automation concept in your production site. Ask for our tesa® EfficienSeal automated dispensing tool to ensure a highly efficient and automated patch application.