Additional Info

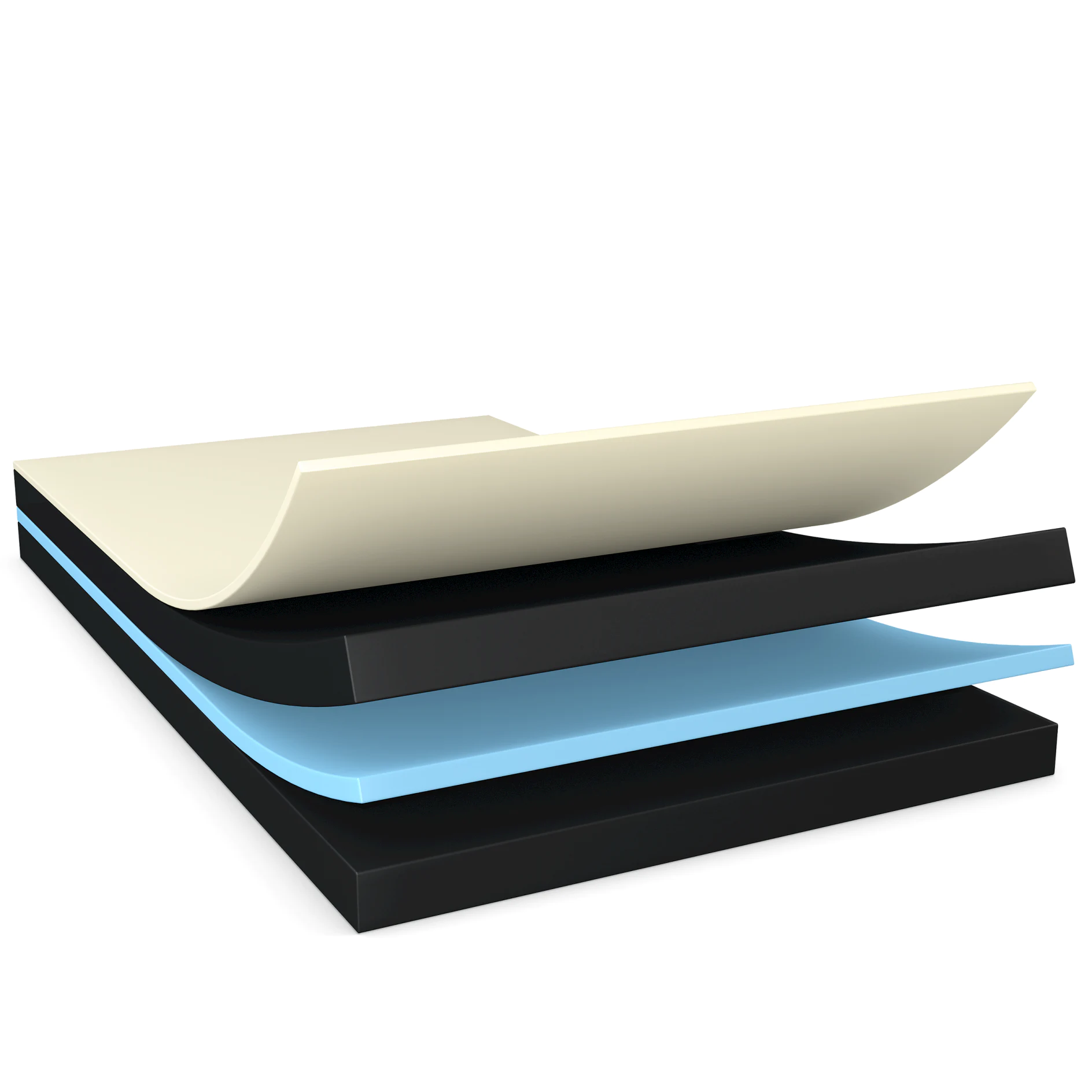

1.Pre-lamination:

tesa HAF® 9402 is laminated before curing. For this process we recommend a temperature between 90°C and 140°C.

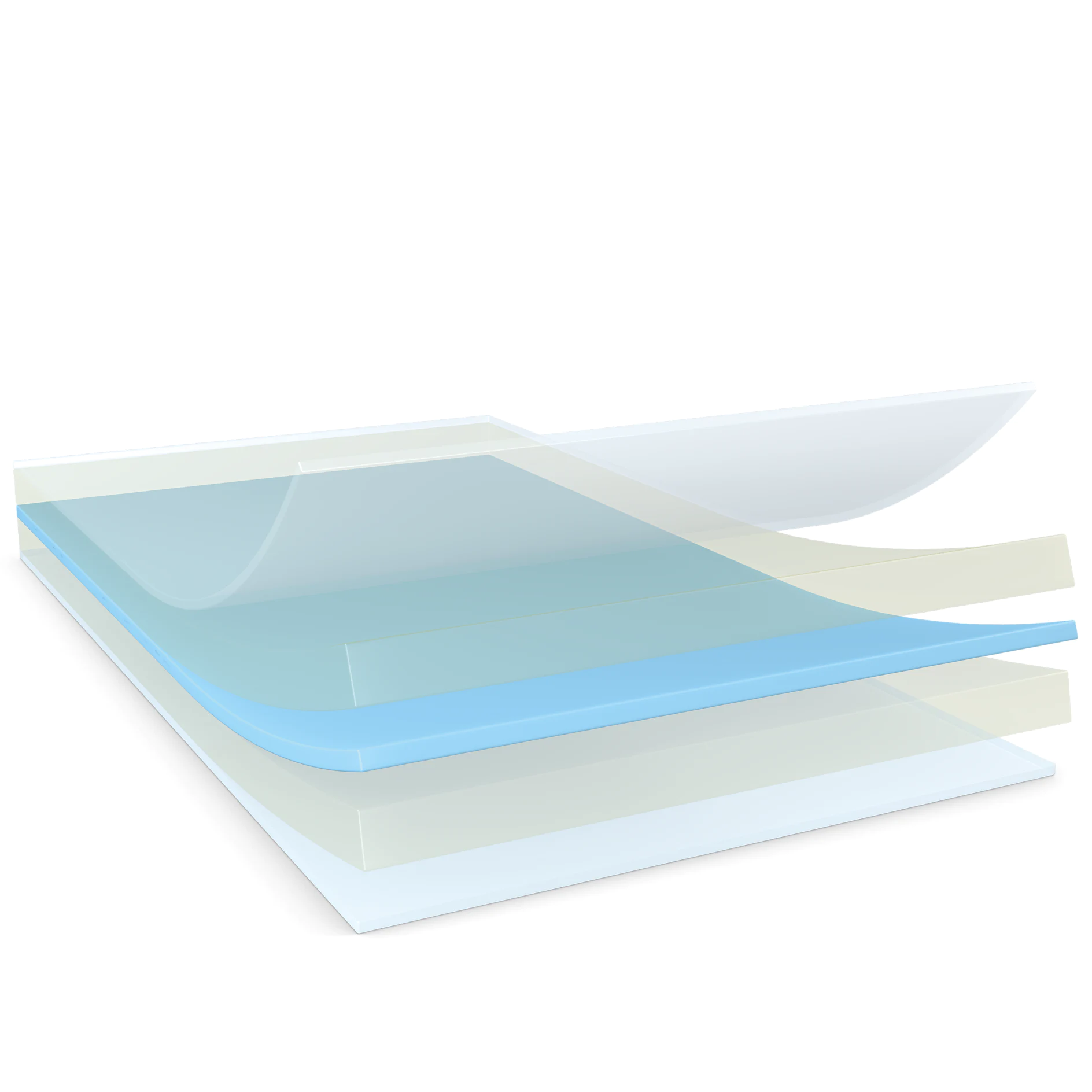

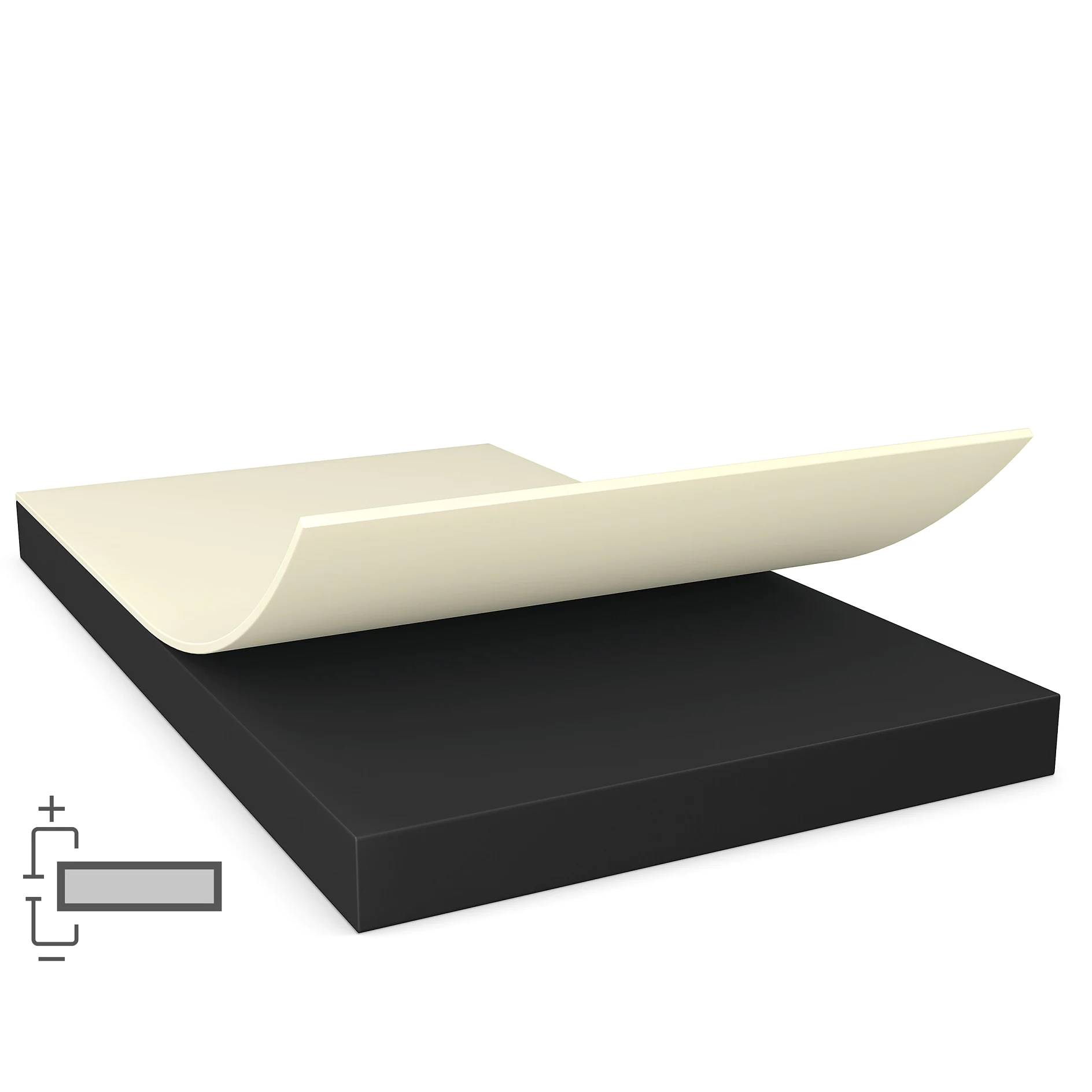

2. Bonding:

The bonding conditions temperature, pressure and time depend on the application. Following parameters can be regarded as a guideline:

Friction linings for synchronizer rings:

1 Temperature: 180 – 230°C

1 Pressure: > 6 bar

1 Time: 3 min

3. Tempering (optional)

To reach maximum bonding strength the bonded parts can be tempered at 180 - 230°C for 30 - 60 min without pressure.

Bonding strength values were obtained under standard laboratory conditions. Value is guaranteed clearance limit checked with each production batch (Material: Etched aluminum test specimen / Bonding conditions: Temp. = 120°C; p = 10 bar; t = 8 min)

To reach maximum bonding strength surfaces should be clean and dry. Storage conditions according to tesa HAF® shelf life concept.