Additional Info

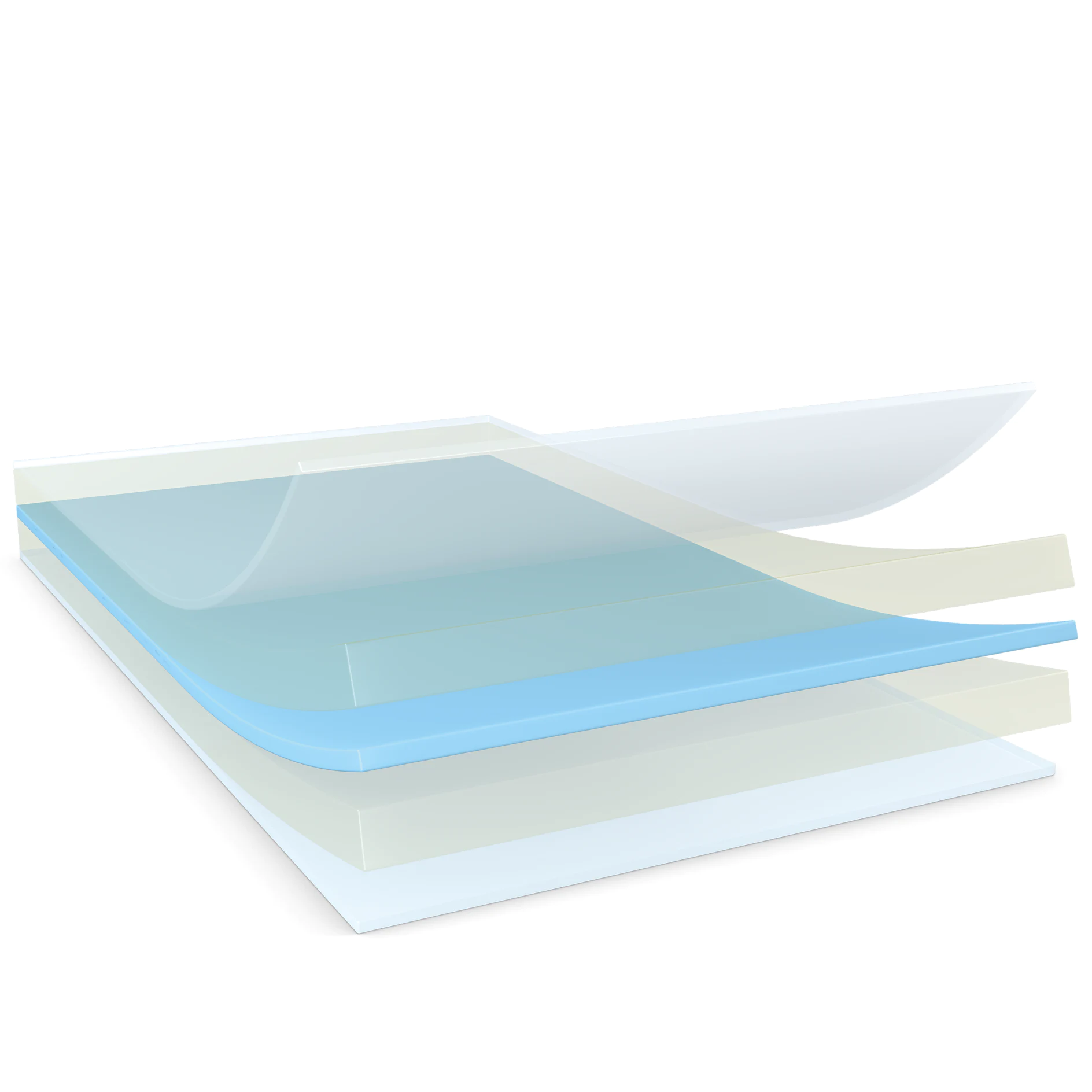

Technical recommendations: tesa HAF® 58451 is not self adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

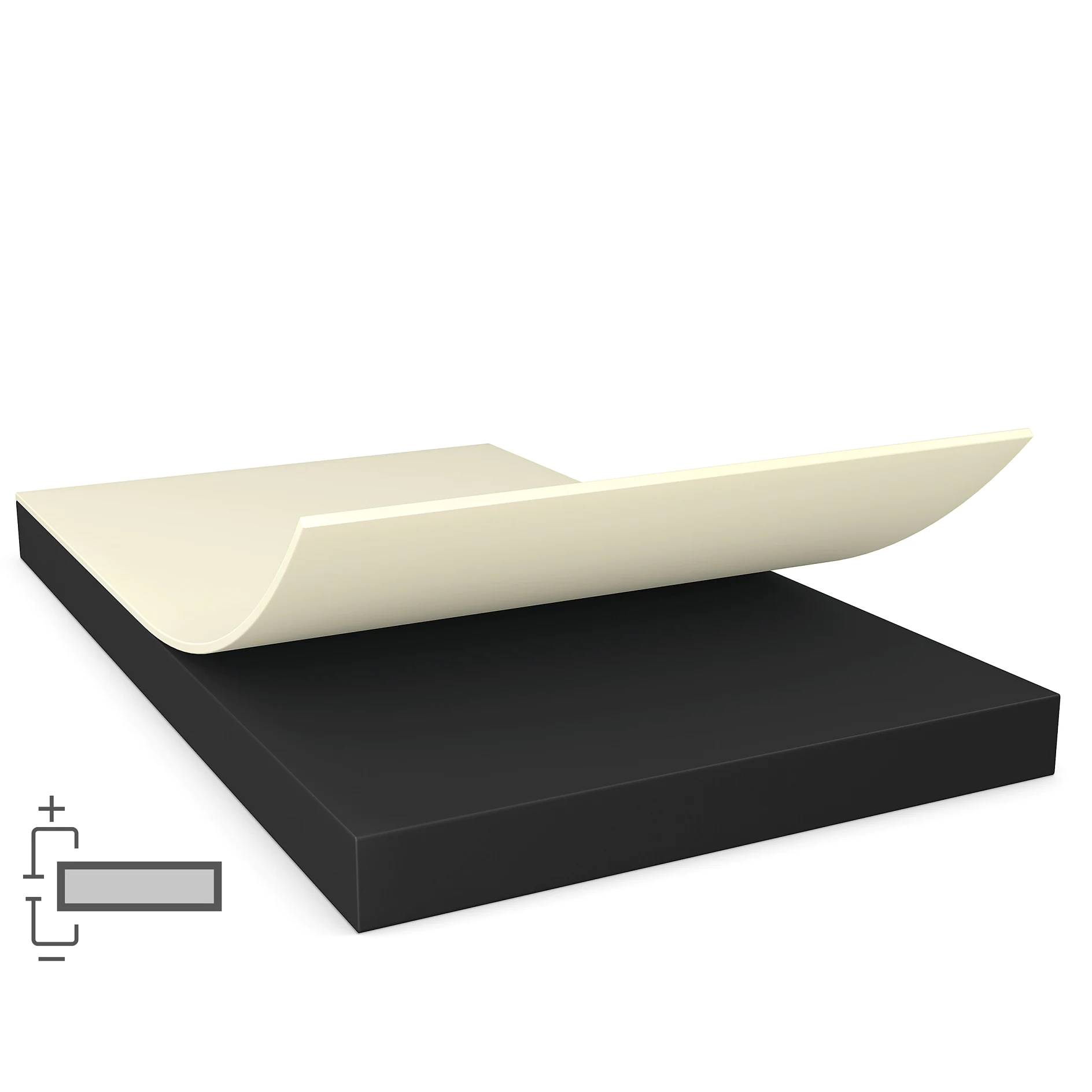

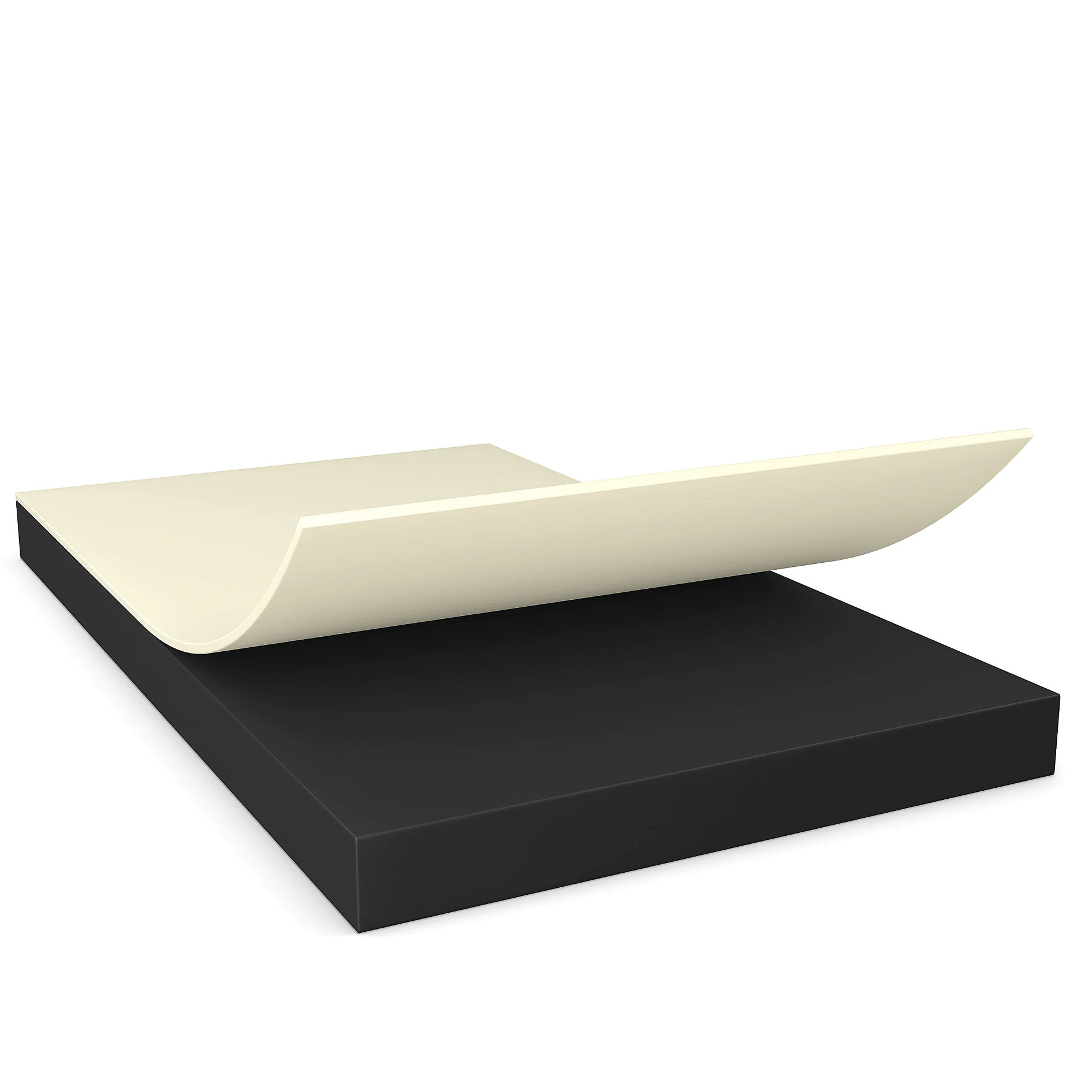

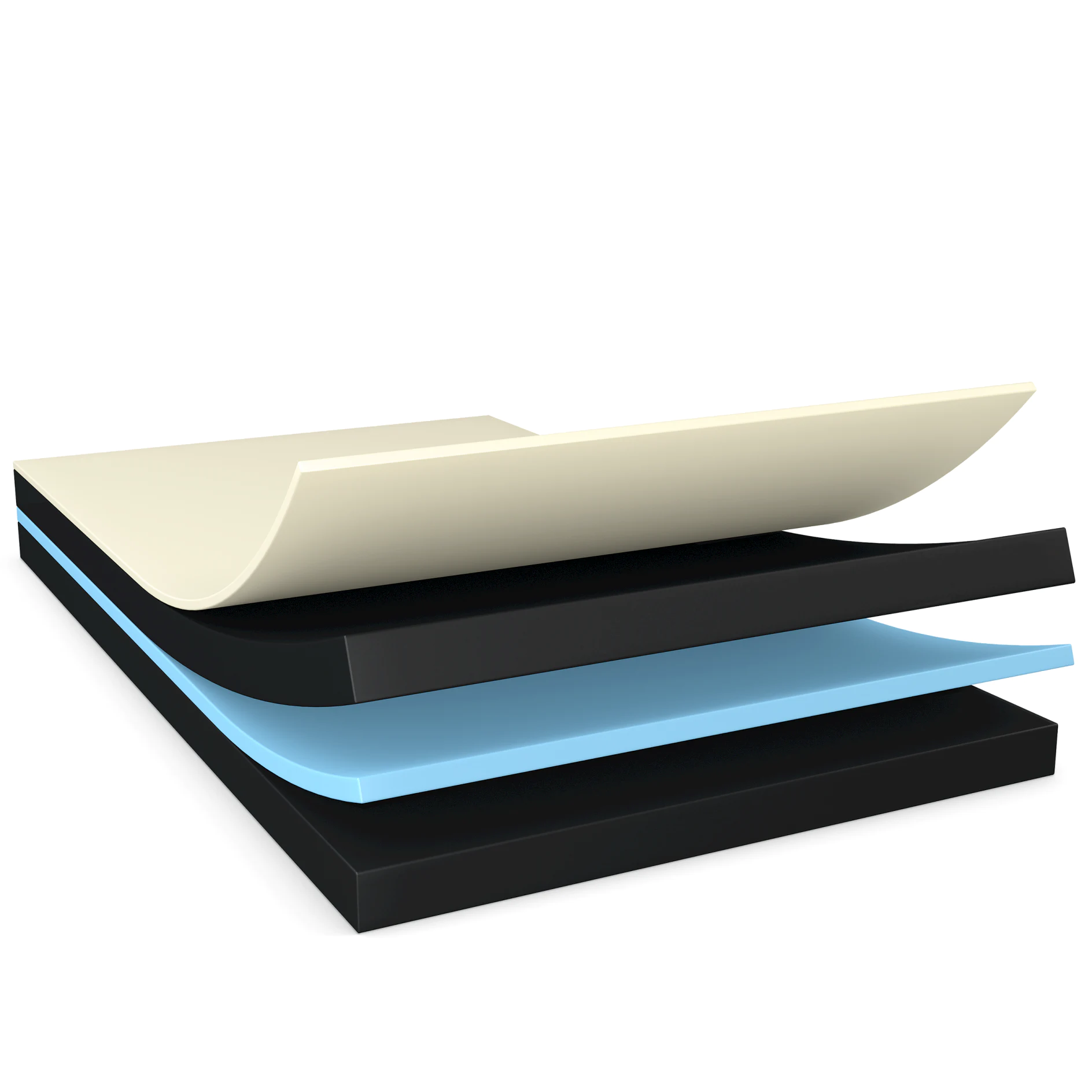

1. Pre-lamination: During pre-lamination, the tape is laminated onto one component.

Setting:

Setting:

1. Pre-lamination: During pre-lamination, the tape is laminated onto one component.

Setting:

- Temperature¹ ≥120 °C

- Pressure² ≥5 bar

- Time ≥5 s

Setting:

- Temperature¹ 120-250 °C

- Pressure² 5-30 bar

- Time 5 s – 3 min