Sandblasting is a powerful surface treatment method that uses abrasive materials propelled by air pressure to remove coatings, eliminate surface impurities, and enhance material durability. To achieve clean, controlled results, selecting the right sandblasting tape is essential. The ideal tape must effectively absorb the impact of abrasive blasting, which varies based on the aggressiveness of the blasting media, air pressure, and treatment duration.

High-performance sandblasting tapes provide reliable surface protection (opens in a new window or tab), ensuring sharp masking lines and preventing damage to sensitive or untreated areas. Whether you're working on metal, glass, or composite surfaces, the right abrasive blasting masking tape (opens in a new window or tab) will significantly improve the quality and efficiency of your process. Sandblasting tapes serve as a versatile masking solution across a wide range of industrial applications.

Key features of our sandblasting tape

We offer premium sandblasting tapes engineered for industrial environments where precision and durability matter. Designed with a variety of high-performance backings and adhesive systems, our tapes ensure fast application, strong adhesion, and reliable surface protection, even under the most abrasive conditions.

Here’s what sets our sandblasting tapes apart:

- High temperature resistance: Our high-temperature sandblasting tapes maintain adhesion and integrity under extreme blasting conditions. Perfect for prolonged exposure to abrasive materials and elevated temperatures.

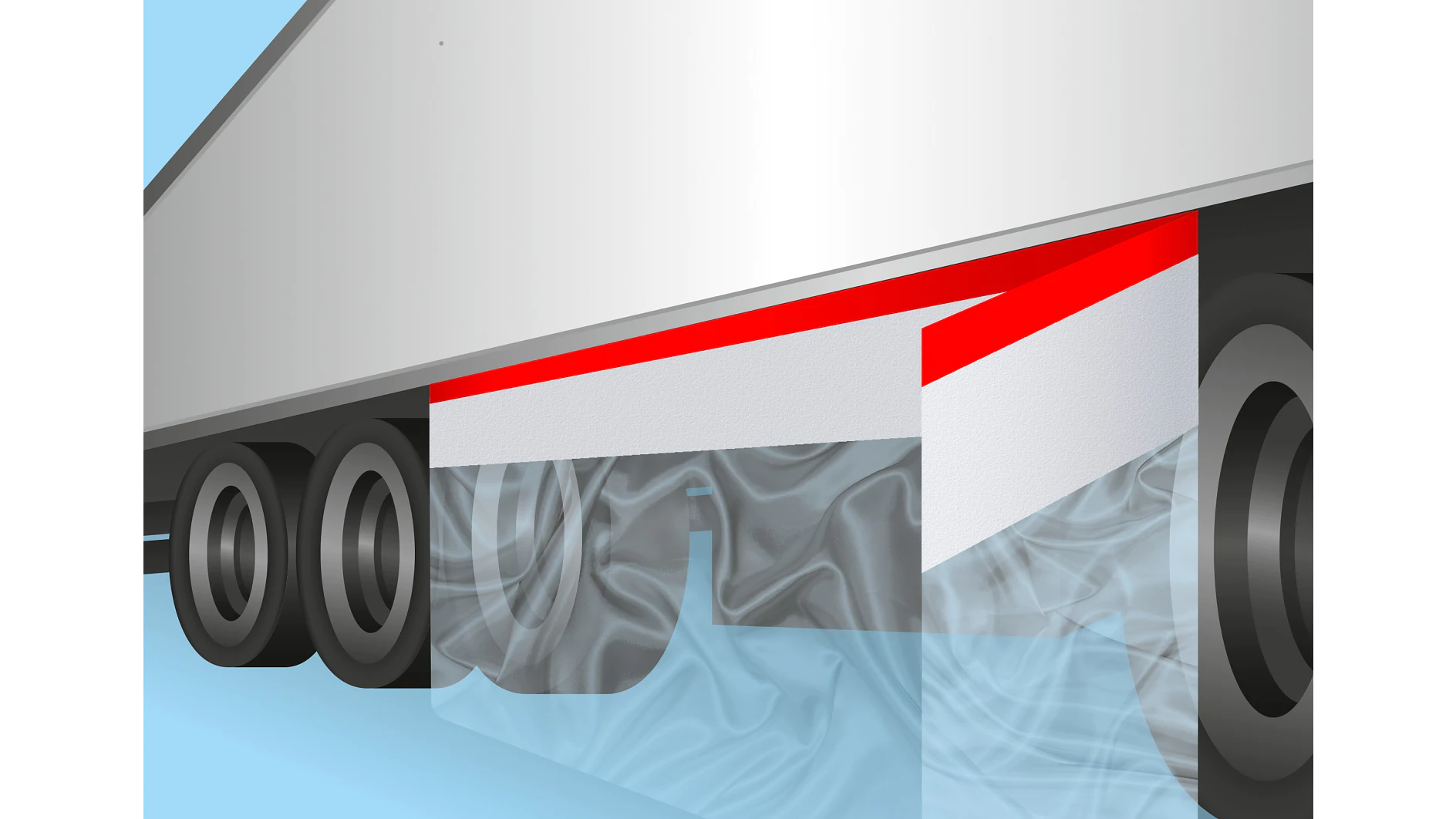

- Multi-layer protection: For demanding applications, apply in multiple layers for enhanced protection. Use tesa® 4688 (opens in a new window or tab) in a red base layer to signal when to stop blasting: improving control and precision.

- Clean removal without residue: Clean removal – no residue, no delays. Reduce cleanup time and maximize process efficiency. Our abrasive blasting masking tapes peel away cleanly, even after intense surface treatment.

- Superior adhesion on various surfaces: Engineered for metals, glass, plastic, and painted surfaces: our industrial sandblasting tapes deliver reliable performance across materials.

- Efficiency-boost: With fewer layers needed compared to traditional products, our tapes reduce time and material usage. Boosting your overall productivity!

- Proven quality and technical support: Backed by multiple field validations and expert engineering support, our tapes meet the highest industrial standards.

Typical applications for sandblasting tape

Our sandblasting tapes are essential in a variety of industries. Their unique ability to withstand abrasive blasting makes them ideal for masking surfaces and ensuring clean, defined edges during the sandblasting process.

Key applications include: masking and protection of sensitive areas, creating sharp patterns on glass and metal, preserving untreated zones during coating removal, and shielding precision components in industrial manufacturing.

Durability of sandblasting tapes in multiple layers

For highly demanding applications, our sandblasting tapes can be applied in multiple layers to enhance impact resistance and surface protection. The detailed comparison table below describes durability levels — low, medium, good, very good — helping you find the best tape when your current solution falls short. This makes it easy to select the strongest and most reliable option for your specific needs. Our high-performance materials often require fewer layers—reducing time and resource consumption while boosting overall efficiency.

| Process parameter: 4 bar/2.5 cm distance | tesa® 4688 (opens in a new window or tab) | tesa® 4432 (opens in a new window or tab) | tesa® 4443 | tesa® 4657 (opens in a new window or tab) | tesa® 4434 (opens in a new window or tab) | |

|---|---|---|---|---|---|---|

| 1 tape layer | low | low | low | low | low | medium |

| 2 tape layers | low | low | medium | medium | medium | good |

| 3 tape layers | low | medium | good | good | good | very good |

Why choose our product?

- Wide range of applications: Our extensive product range caters to even the most demanding applications.

- Proven quality: Our tapes offer stable and reliable quality, validated through multiple tests.

- Expert technical support: Benefit from the expertise of our experienced and highly skilled engineers.

At tesa, sandblasting tapes are engineered to meet the challenges of abrasive blasting across various industrial environments. Depending on the application, our tapes differ in backing material, adhesive type, adhesion strength, total thickness, tensile strength, durability, temperature resistance, and color – ensuring the right solution for every masking need during sandblasting.

Products

FAQ

What are sandblasting tapes used for?

Sandblasting tapes are used to mask and protect specific surfaces during abrasive blasting processes, preventing damage or erosion from high-pressure media.

What types of surfaces can sandblasting tapes protect?

They can be used on metal, glass, stone, wood, and ceramic surfaces to shield areas that should remain unaffected by the sandblasting.

Which features should I look for in a high-quality sandblasting tape?

Look for strong adhesion, high resistance to abrasion, clean removability, and durability under extreme pressure and temperature conditions.

How do I apply sandblasting tape for best results?

Ensure the surface is clean and dry, apply the tape firmly to prevent lifting, and press down edges to avoid media seeping underneath during blasting.

Is there a specific tape for high-pressure sandblasting?

Yes, heavy-duty sandblasting tapes are specifically designed to withstand high-pressure and deep-etching applications. For high-pressure sandblasting, we recommend using tesa® 4434, which offers superior durability and resistance under intense conditions. For more delicate or shorter blasting tasks, tapes like tesa® 4432 (opens in a new window or tab) or tesa® 4443 provide excellent masking with clean removal and are ideal for detailed stencil work.