Additional Info

Technical recommendations:

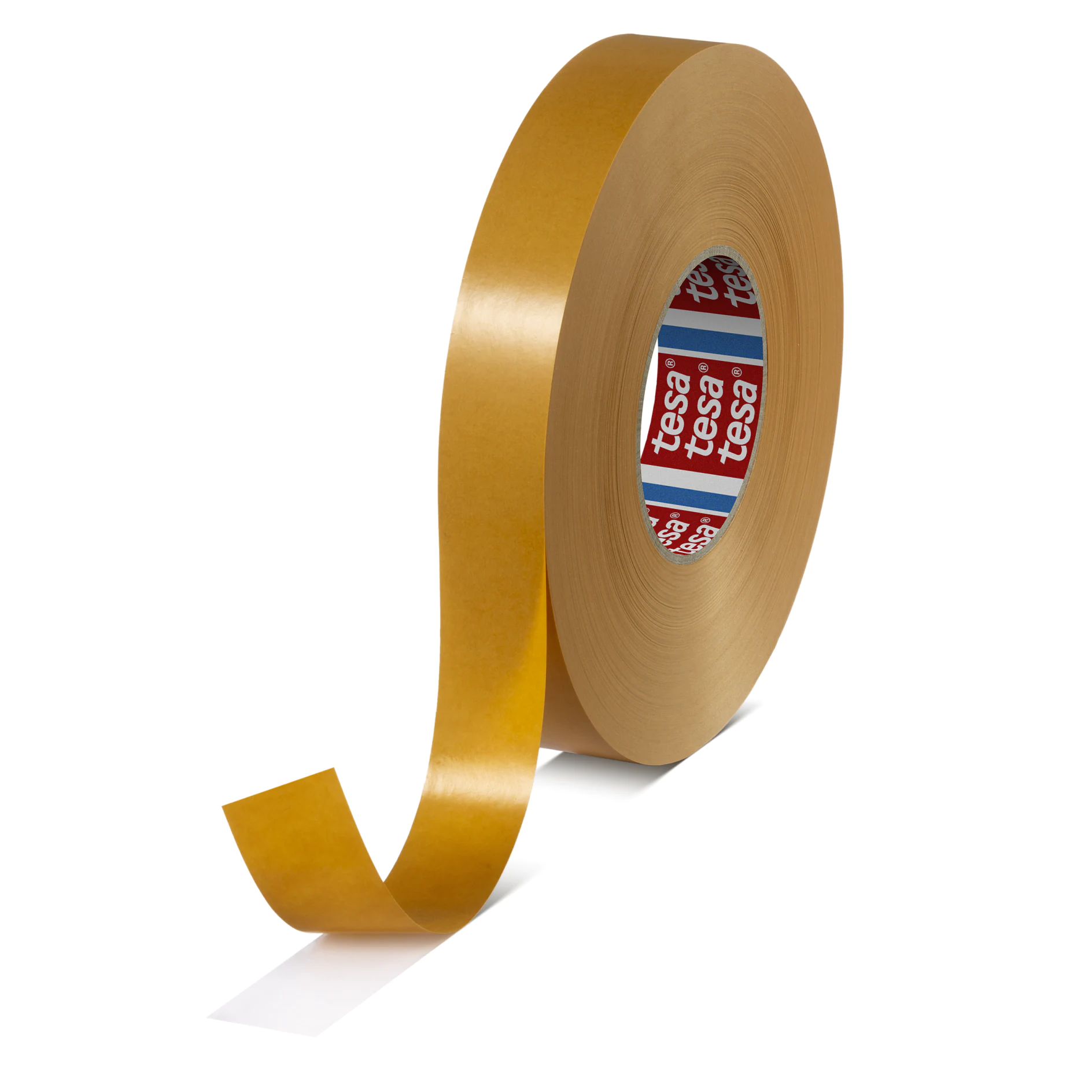

tesa® XPU 58701 is not self-adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

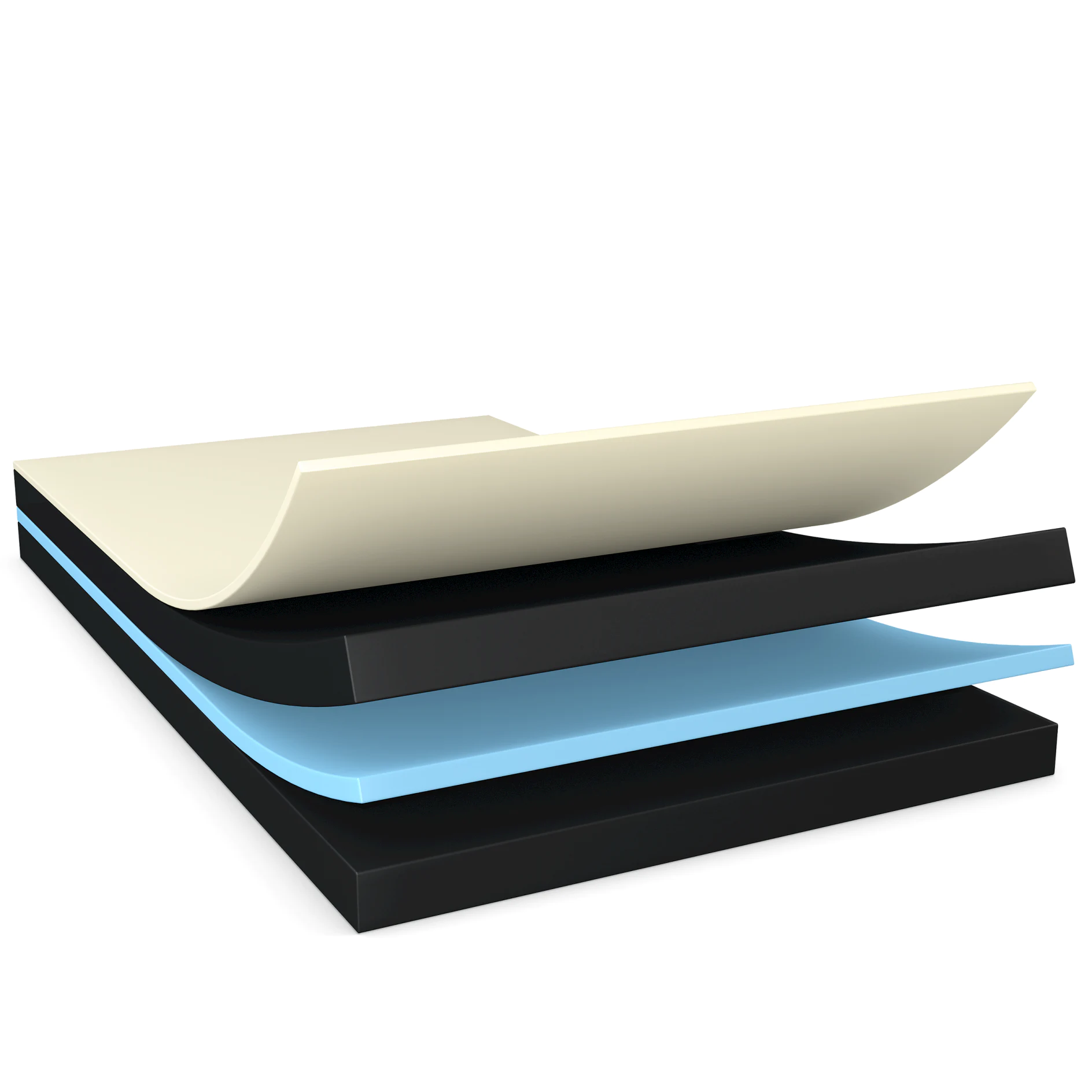

Pre-lamination

During pre-lamination, laminate the adhesive tape onto the first component.

Setting:

Bonding

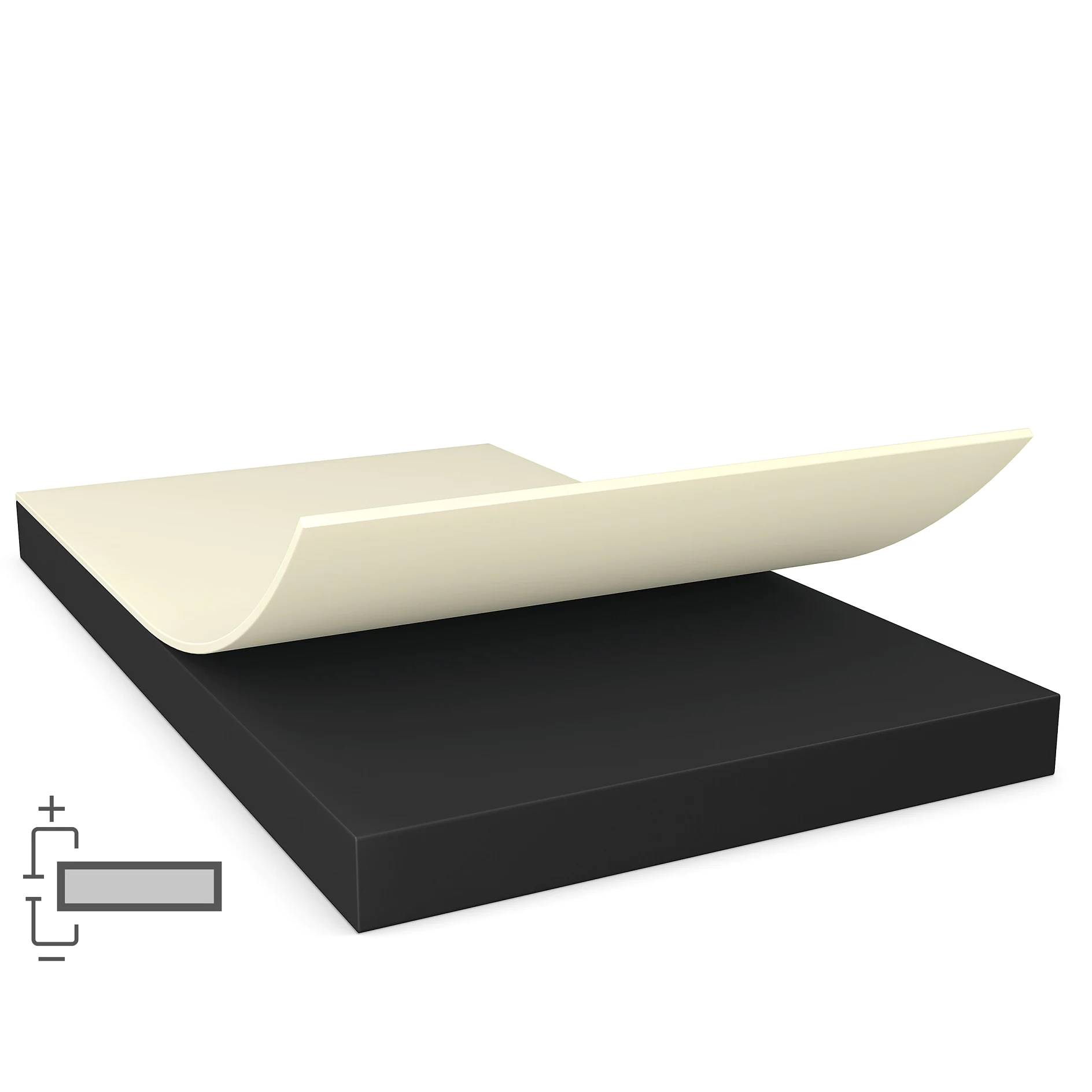

Remove the liner from tape after the pre-lamination step.

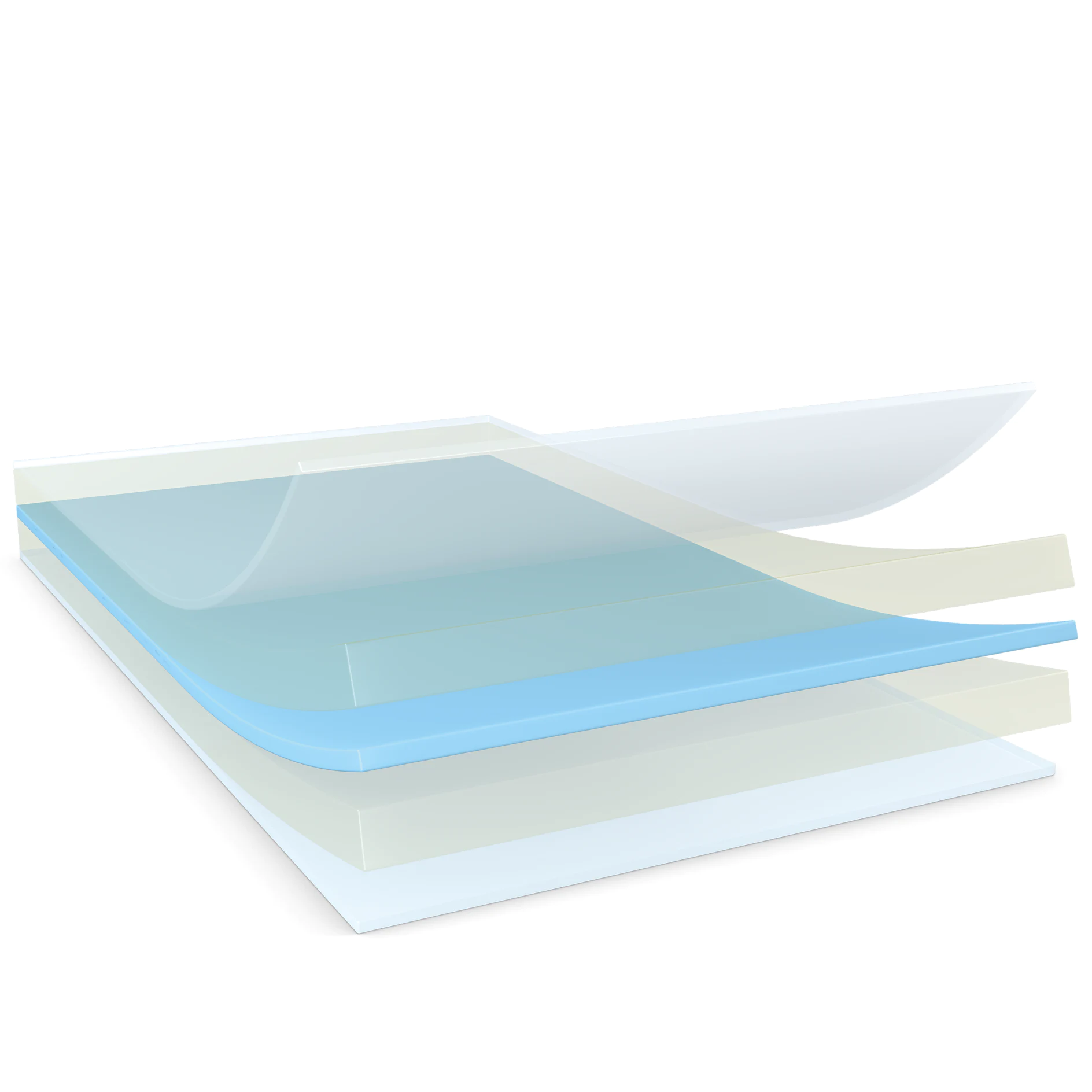

Position the second component. Apply temperature and pressure for the bonding time to reach sufficient bonding strength.

PC/PC:

Setting:

Setting:

Bonding strength values were obtained under standard laboratory conditions.

PC/PC: bonding conditions: temperature = 110 °C (120 °C jig); pressure = 5 bar; time = 60 sec

Storage: tesa® recommends storage in original packaging in cool and dry conditions.

‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line.

‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transferred from jig surface directly to the bonding area.

tesa® XPU 58701 is not self-adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

Pre-lamination

During pre-lamination, laminate the adhesive tape onto the first component.

Setting:

- Temperature¹ 55-65 °C

- Pressure² 3 bar

- Time 5 – 20 s

Bonding

Remove the liner from tape after the pre-lamination step.

Position the second component. Apply temperature and pressure for the bonding time to reach sufficient bonding strength.

PC/PC:

Setting:

- Temperature¹ 80 – 140 °C

- Pressure² 5 bar

- Time 10 – 120 s

Setting:

- Temperature¹ 110 – 190 °C

- Pressure² 5 bar

- Time 20 – 120 s

Bonding strength values were obtained under standard laboratory conditions.

PC/PC: bonding conditions: temperature = 110 °C (120 °C jig); pressure = 5 bar; time = 60 sec

Storage: tesa® recommends storage in original packaging in cool and dry conditions.

‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line.

‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transferred from jig surface directly to the bonding area.