How alesco combines highest quality with more sustainability

Markets

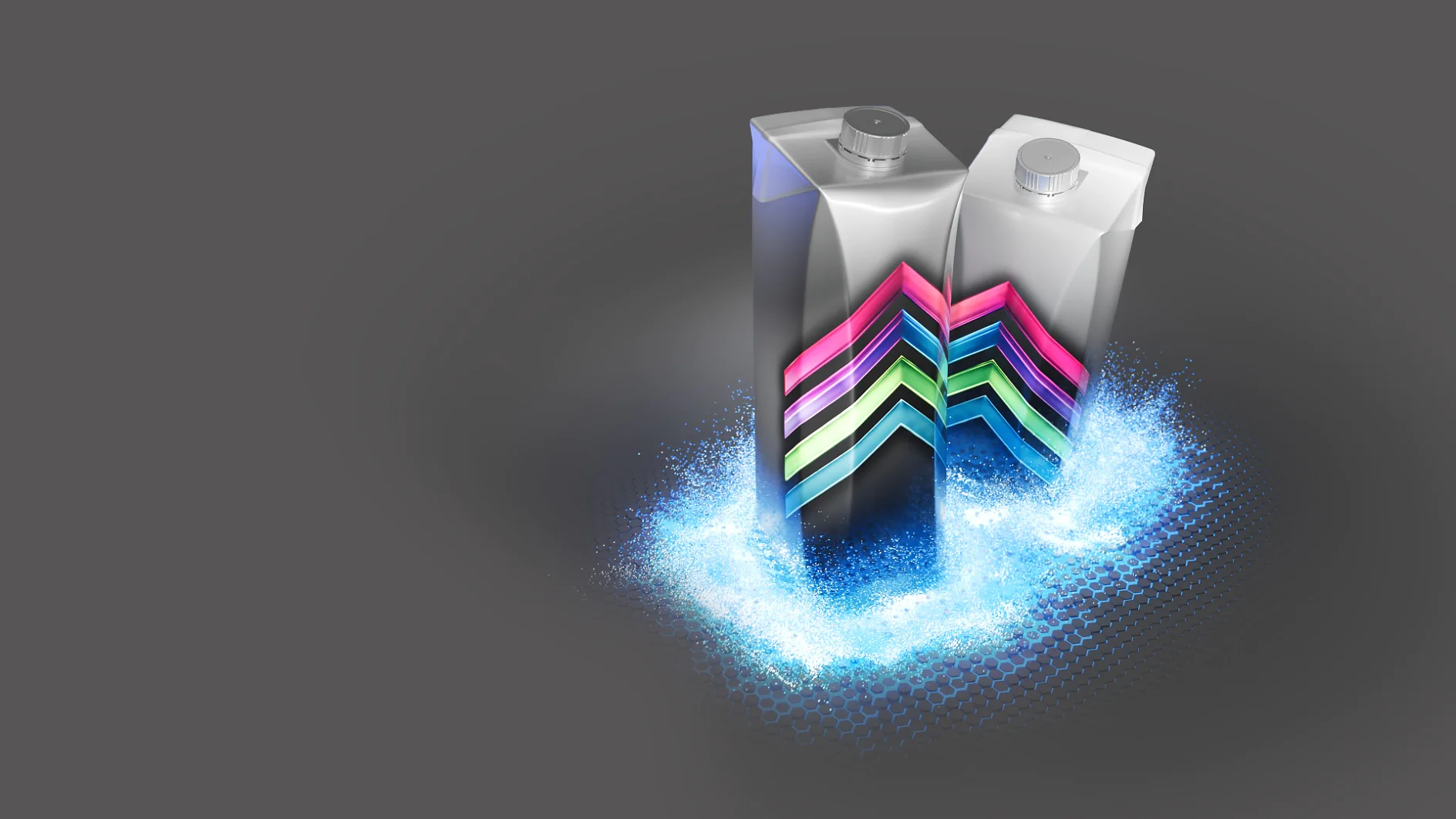

High-quality packaging from alesco with a clear focus on more sustainable solutions

alesco dresses brands more sustainable

Continuous investments in state-of-the-art extrusion systems and printing machines ensure top-quality products to all customers and a focus on more sustainable solutions is obvious both in the assortment and in production processes.

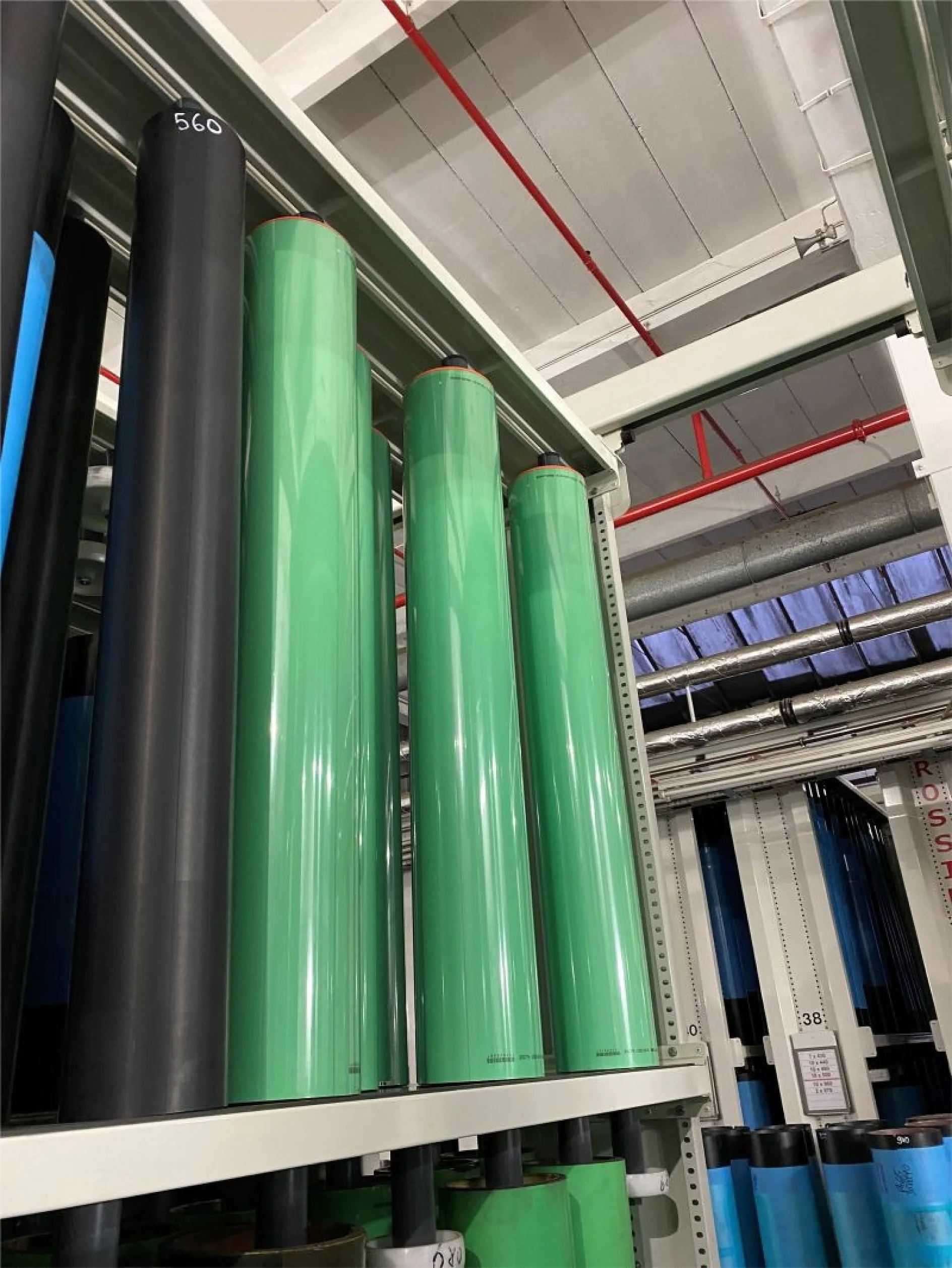

Technology at alesco

Film extrusion at alesco takes place in a variety of thicknesses, at width up to 3,000 mm, for many materials, transparent or colored, in mono or co-ex quality.

Film printing happens at four different printing machines, printing up to ten colors in flexo, with a clear focus on highest quality and process efficiency, providing repeats over 1,000 mm.

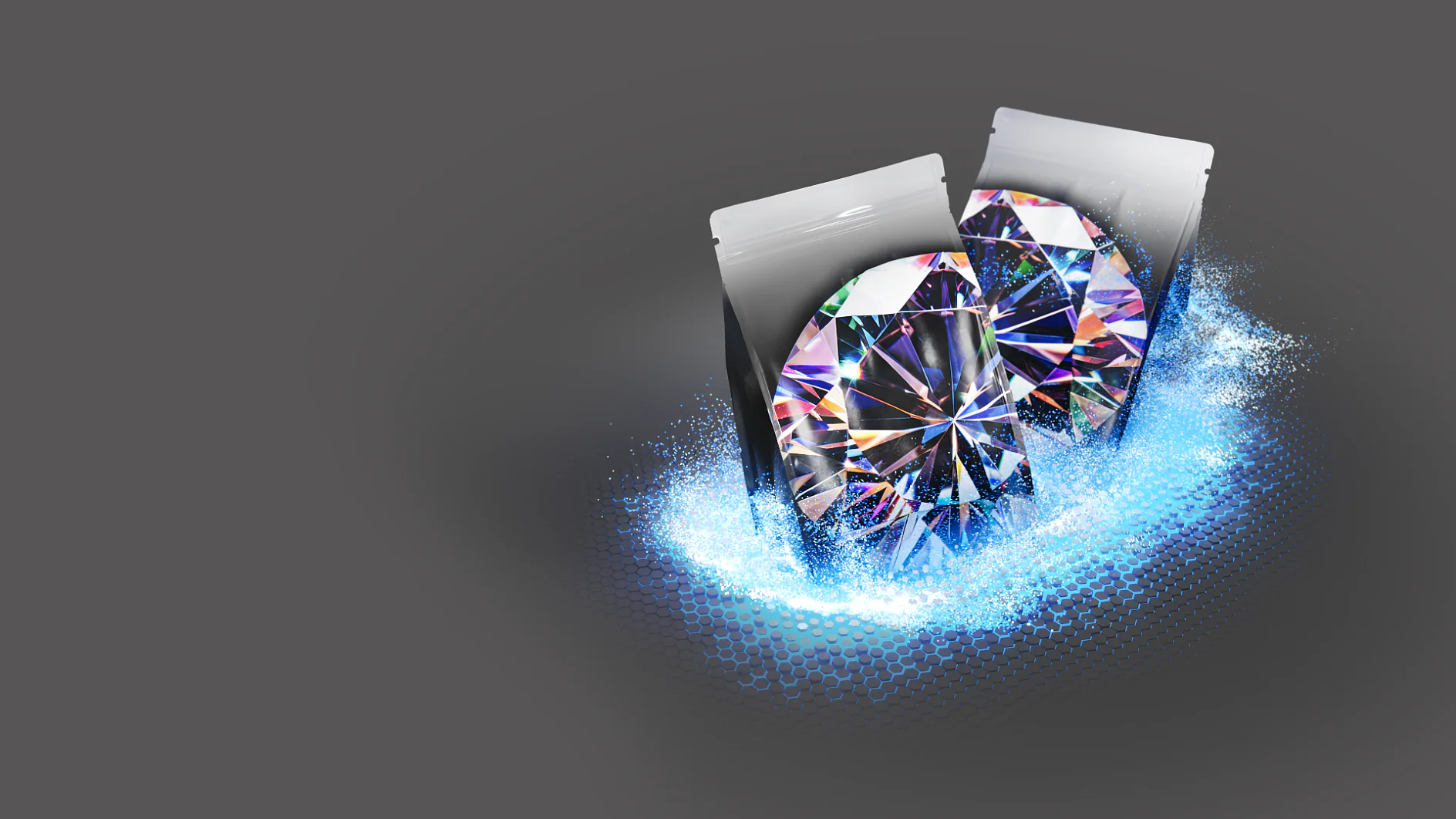

Film converting into bags and carriers is the last production step done at alesco, according to customer requirements.

A clear focus on the enviroment

alesco's focus on more sustainable solutions is multi-layered:

- The assortment features biodegradable and bio-based films,

- the property of being 'mono-material' ensures recyclability,

- alesco has an in-house recycling department,

- they continuously work to reduce film thicknesses for lesser material consumption,

- and have an overall focus on lean processes and short supply chains.

Recently, one of alesco's developments of a reduced-thickness shrink film with up to 80% post-consumer recyclate has been rewarded with the "PLASTIC RECYCLING AWARD EUROPE 2022" and their "RECOMP80" polyethylene PCR film (with a minimum of 80% PCR content) is certified by the German ecolabel 'Blue Angel'.

Printing with tesa® plate mounting solutions

At alesco, both our plate mounting technologies - tesa® Softprint plate mounting tape and tesa® Twinlock (opens in a new window or tab)self-adhesive sleeves - are in use.

tesa® Twinlock is used on the most frequently recurring repeats and has been proven to be especially successful for print designs susceptible to vibrations. The tesa® Softprint products in use at alesco are significantly supporting fast mounting processes and trouble-free plate demounting after printing. To reduce complexity, alesco has been able to switch the plate mounting tapes to just one foam hardness, while still achieving highest print quality and efficient processes.

With tesa® Twinlock it was not only the potential ROI, thanks to the time and material savings that convinced us, but also the high-quality print results ... We have also achieved an important objective for sustainability by reducing waste.

Managing Director

A common problem: vibrations during flexographic printing. There are several methods to get rid of this problem. We have found our optimal solution: the Twinlock sleeves from tesa. These sleeves are self-adhesive and, above all, reusable – another step towards sustainability.

Alexander Appoew, 'Head of Printing' at alesco with three tesa colleagues

© alesco

At tesa, we continuously invest in our plate mounting products and want to optimize them or offer customized products wherever we can.

That's why we have our flexo experts out in the field to learn directly what is working perfectly and what can be improved and alesco has proven to be a great partner for us in the past to learn and continuously improve together.

Thank you for the partnership, we are looking forward to our continued journey together!