Additional Info

Adhesion properties:

Peel adhesion to polyester fabric: 7 N/cm

Technical recommendations:

tesa® LTT 8741 is not self-adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

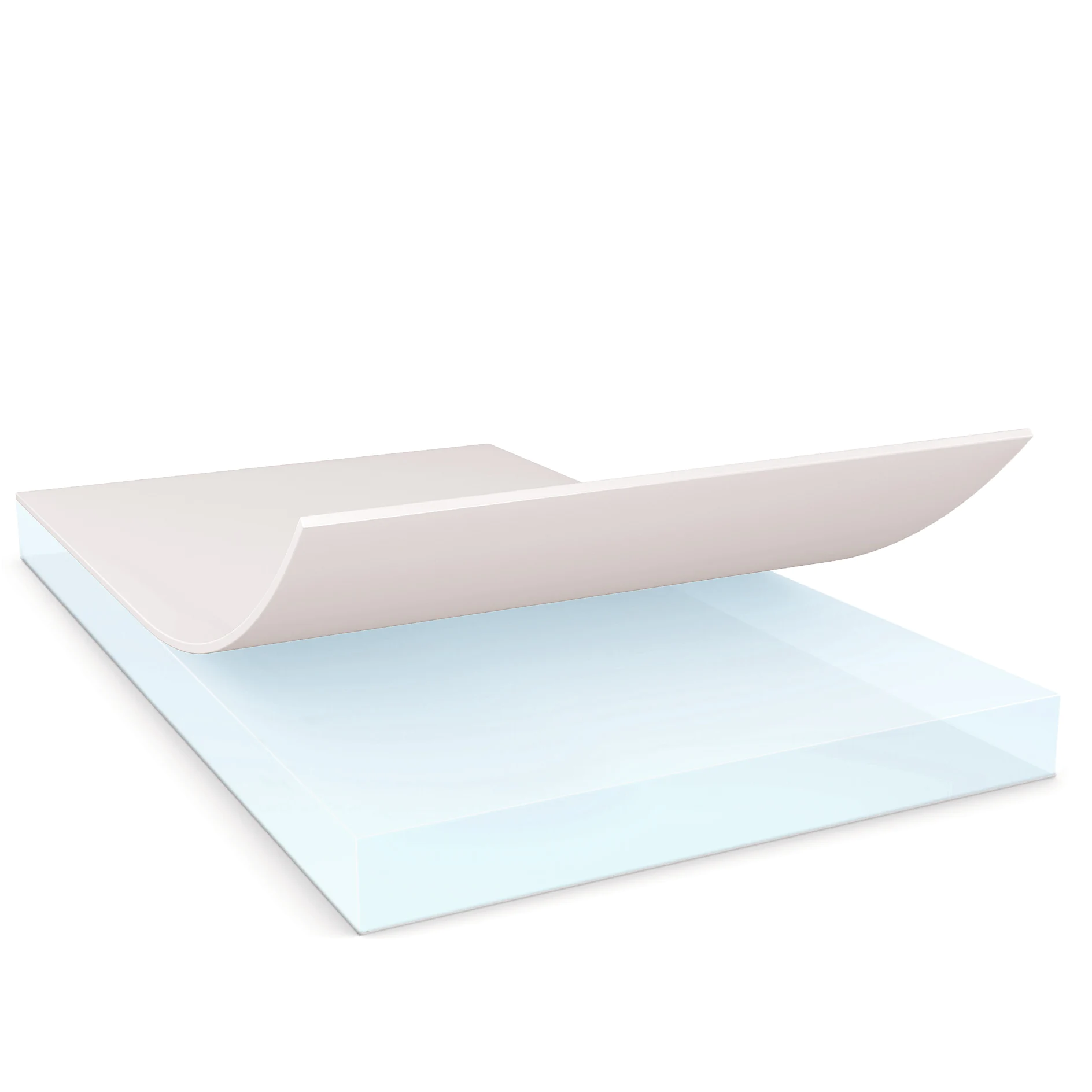

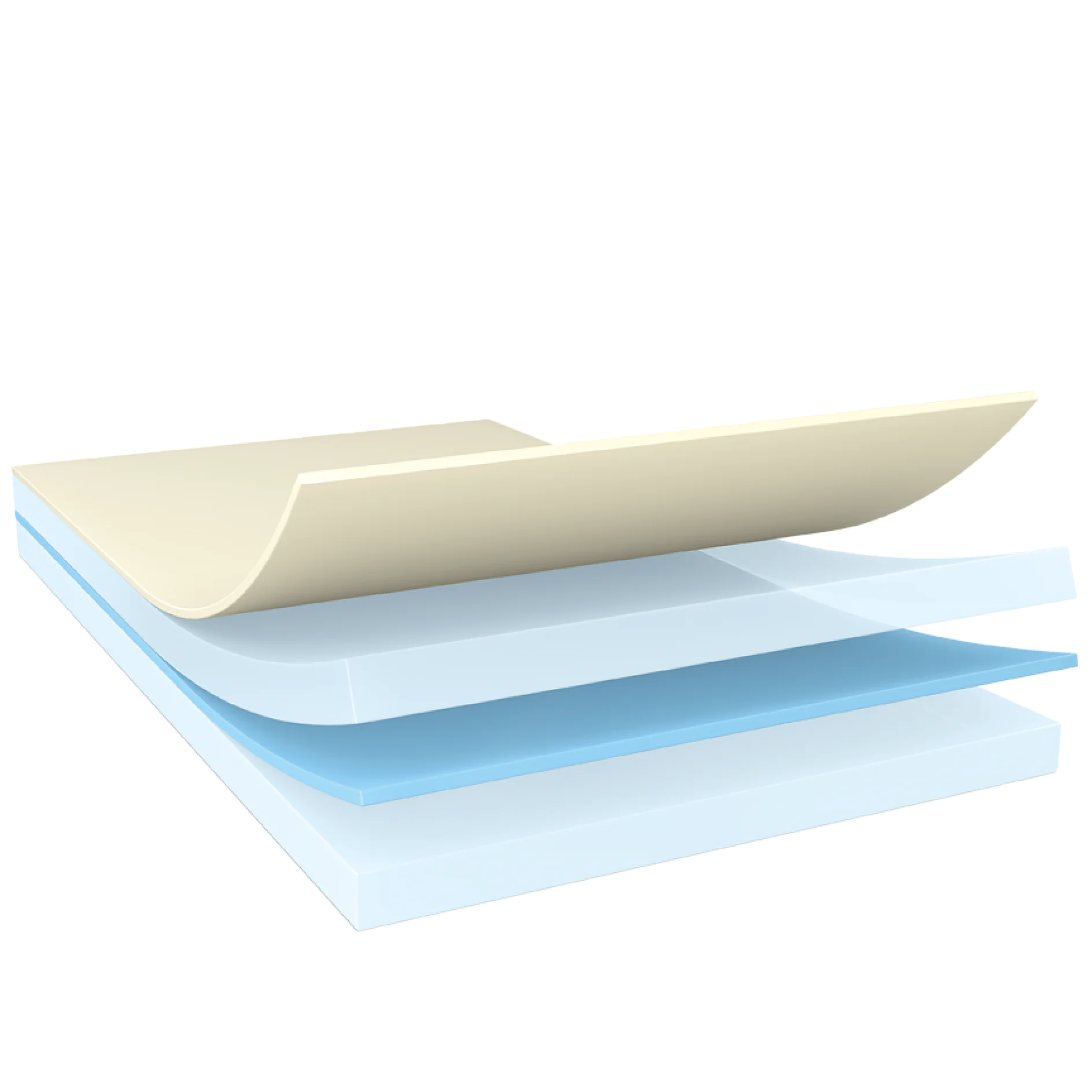

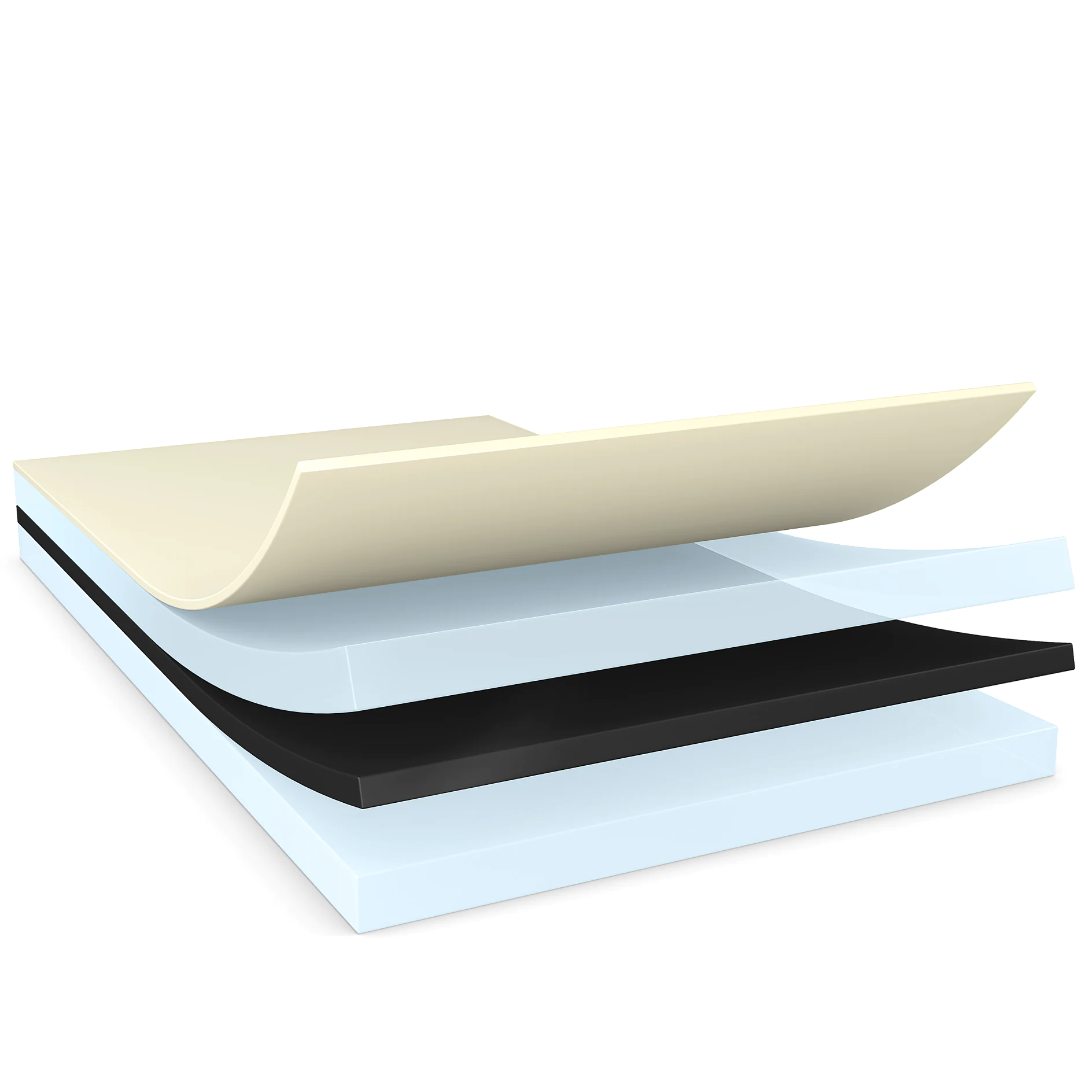

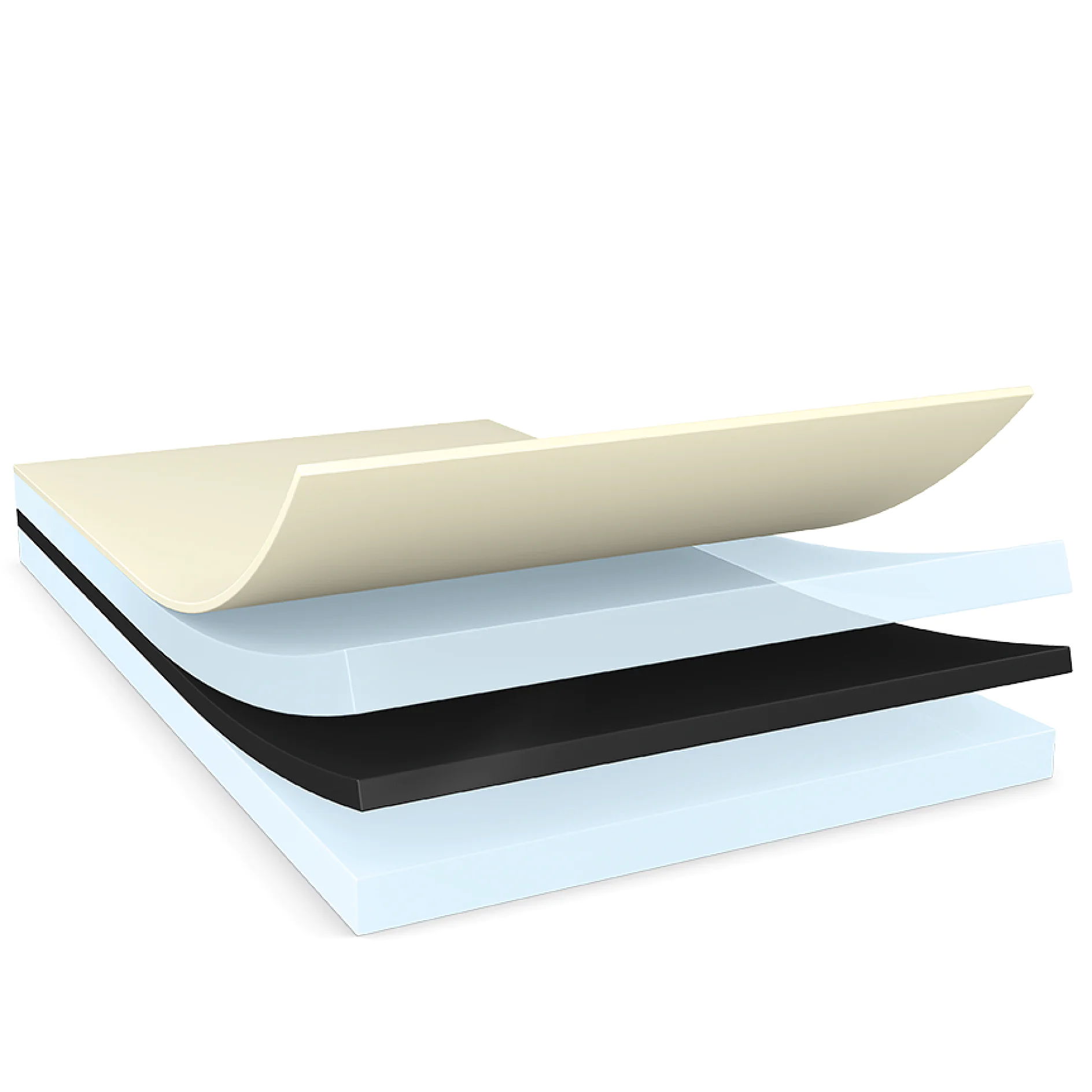

1) Pre-lamination

During pre-lamination, laminate the film onto the first component.

Setting:

Remove the liner from the film after the pre-lamination step. Position the second component. Apply temperature and pressure for the bonding time to reach sufficient bonding strength.

Setting:

Short cycle times can be achieved at 110 °C bond line temperature. For activation at lower temperatures, increase the heat-press time or combine a short heat-press step with oven curing.

Peel adhesion values were obtained under standard laboratory conditions (reinforcement backing 23 µm PET; bonding conditions: temperature = 90 °C; pressure = 5 bar; time = 120 sec).

To reach maximum bonding strength, surfaces should be clean and dry. Allow at least 1-2 hours dwell-time after bonding before performance testing. Final bonding strength will be reached after 24 hours.

¹ ‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line. ² ‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transferred from jig surface directly to the bonding area.

Peel adhesion to polyester fabric: 7 N/cm

Technical recommendations:

tesa® LTT 8741 is not self-adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

1) Pre-lamination

During pre-lamination, laminate the film onto the first component.

Setting:

- Temperature¹ 60 – 90 °C

- Pressure² 1 – 5 bar

- Time 5 – 20 s

Remove the liner from the film after the pre-lamination step. Position the second component. Apply temperature and pressure for the bonding time to reach sufficient bonding strength.

Setting:

- Temperature¹ 80 – 120 °C

- Pressure² 1 – 5 bar

- Time 10 – 480 s

Short cycle times can be achieved at 110 °C bond line temperature. For activation at lower temperatures, increase the heat-press time or combine a short heat-press step with oven curing.

Peel adhesion values were obtained under standard laboratory conditions (reinforcement backing 23 µm PET; bonding conditions: temperature = 90 °C; pressure = 5 bar; time = 120 sec).

To reach maximum bonding strength, surfaces should be clean and dry. Allow at least 1-2 hours dwell-time after bonding before performance testing. Final bonding strength will be reached after 24 hours.

¹ ‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line. ² ‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transferred from jig surface directly to the bonding area.