Given the high levels of change in the commercial print packaging industry, it can be hard to say what lies ahead. As the industry continues to evolve, however, one thing is certain: the use of standardized production processes to remain competitively priced and maintain print quality is a must.

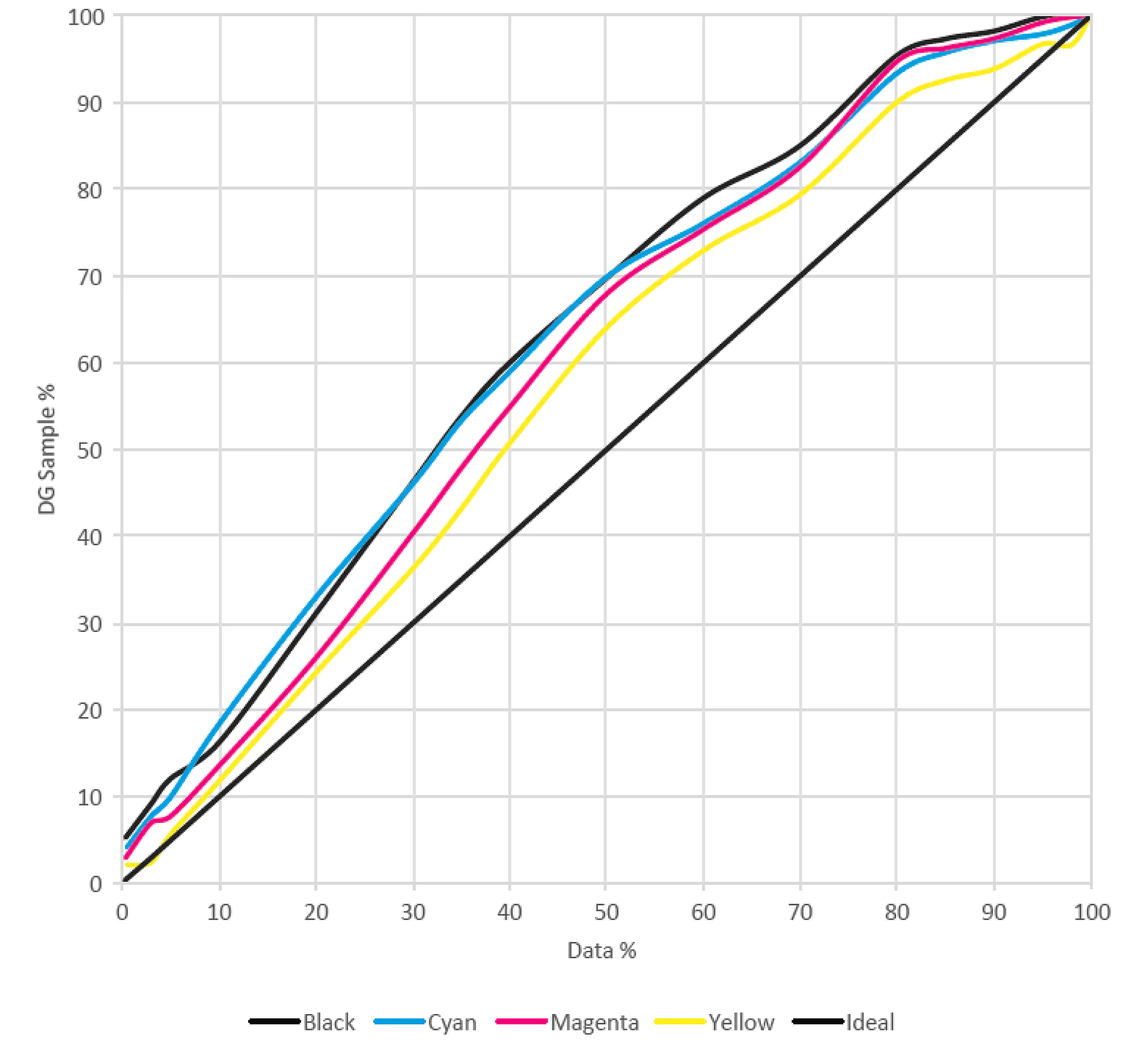

As average run sizes continue to decline, commercial printers are actively looking to optimize their processes in order to achieve maximum profitability and throughput. Extended color gamut (ECG) printing is a commonly recognized way to improve efficiencies and create consistent and precise quality. The concept uses a fixed range of 7 colors (CMYK +3 extra predefined inks) to improve productivity through short print runs by eliminating ink changes between every job. The challenge of implementing ECG printing lies in the level of harmonization during each production step.

Plate mounting tapes have a significant influence on this success because they interact with many elements such as plates, sleeves, ink, anilox, and the printing machine itself. Adhesive plate mounting tapes are a key component of print production because they are involved in every process step: mounting, printing and demounting.

In order to support flexographic printers when implementing these standardized processes we created a patented adhesive system called SNAP-ON technology, this enhances our tesa Softprint® plate mounting offering.

SNAP-ON technology is a new generation of pressure-sensitive adhesives to support printers in their need for higher process efficiency. The advantages of the SNAP-ON technology are based on a perfect balance of adhesive performance and high quality foam to ensure the following:

- Fast job changeovers

- Secure press runs

- Excellent print quality

- Easy and clean demounting properties