Intelligent adhesive tape solutions for entrance doors

Our products offer a durable bond, support flexibility in design, and lead to faster production processes.

Our products offer a durable bond, support flexibility in design, and lead to faster production processes.

Technologies

Contemporary residential entrance doors combine a clean look with new materials, durability, and good thermal insulation values. Our range of pressure-sensitive adhesive tapes is based on a modern and efficient bonding method: Our products offer a durable bond, support flexibility in design, and lead to faster production processes.

The door industry uses tapes as a modern bonding technology more and more as an alternative to conventional fastening methods such as welding, bolts, or rivets. Next to the familiar liquid adhesives, double-sided tape solutions are coming into focus. At present, conventional attachment methods are still used in this industry for the most part. Curing times, sealing processes, and mechanical challenges can generate considerable expenditures of time as well as technical and manual effort. Our double-sided adhesive tapes make these processes simpler, quicker, and safer.

Whether for bonding of door panels, the attachment of decorative trims or kick plates, the mounting of insulation foam, or the bonding of glass elements – we have the right solution for every bonding task. The benefits of having an immediate bond without curing time, as well as a fast and clean bonding process are valid for all double-sided tape applications.

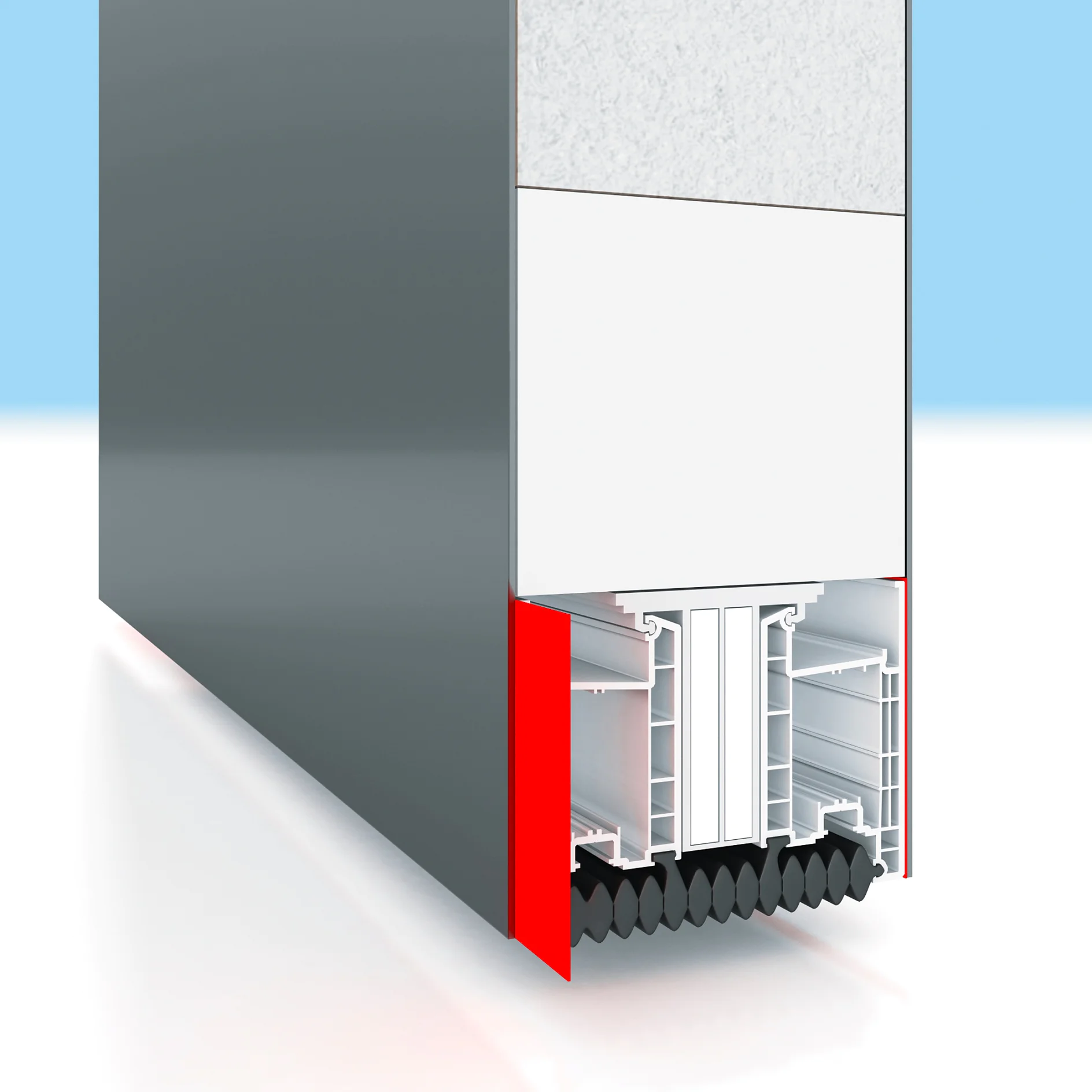

Flush doors with frame-concealing panels are becoming increasingly popular. Door manufacturers can implement their design concept, achieve a durable bond, and achieve a fast assembly process by using our viscoelastic tesa® ACXplus 707x series.

Viscoelasticity characterizes a material behaviour by which elastic recovery provides internal strength while having a particular capability to compensate for mechanical stresses. The balance between elastic and viscous properties not only provides optimum wetting of different substrates, but also absorbs dynamic forces and vibrations. This ensures the dimensional stability and long service life of the bond. This superior bond is resistant to high natural temperatures, weather and UV.

Decorative elements, such as metal trims or glass, give standard entrance doors their individual look. Glass or window elements and cover frames can be assembled in a fast and flexible way using our products. For exceptional bonding strength tesa® ACXplus 707x series can be used; for smaller elements our tesa® 625xx series is also suitable for this application. By offering a range of thicknesses, we support design flexibility for the manufacturer.

Metal kick plates protect the door panel from daily weathering and wear. Using tesa® ACXplus 7072 to bond the metal sheets to the door panels provides a thin gap design and levels out differing thermal expansions of the two bonded materials. In addition, a high bonding strength as well as cold shock are achieved by using a double-sided tape.

Pressure-sensitive adhesive tapes are a proven bonding technology that provide benefits in quality, assembly speed, and design.

Within our wide range of adhesive tape solutions, we offer different products for the door industry. The advantages are obvious: user-friendly, clean, and effective – double-sided tapes optimize both the assembly speed and the optical and technical quality in equal measure. We have tailored our product range to meet special application needs. As a result, today the manufacturers of residential entrance doors and their components (door panels, frames) can fall back on a product range made to meet their requirements.

The quality of the end product is improved by using our double-sided tapes: Our tapes compensate for irregular or uneven surfaces and therefore gaps between the bonded materials are eliminated. They can also compensate for tension and dissipate stresses, and reduce the risk of corrosion.

The assembly process is faster and healthier as curing time is no longer necessary and the process complexity is reduced. A cleaner production side and a healthy work environment are key benefits from using our tapes. Working with our tapes stands for working with controlled parameters during a production process.