tesa® ACXplus Primerless:

The future of automotive adhesion

Reliable adhesion for automotive exteriors - streamline production, enhance durability, and reduce complexity.

Adhesive solutions for modern challenges

The automotive industry faces new mounting challenges in exterior attachment part assembly. With components growing larger and heavier, and made from increasingly diverse materials like PP and EPDM, traditional adhesives struggle to perform. Harsh environmental conditions, including extreme temperatures and humidity, further test their durability.

At the same time, manufacturers demand streamlined processes without sacrificing design freedom. tesa® ACXplus Primerless tackles these issues with a new line of primerless acrylic foam tape, offering reliable adhesion, reduced complexity, and unmatched durability for modern automotive needs.

A new standard in adhesion

OEMs and OES are seeking a tape that provides design flexibility for large attachment parts made of all kinds of PP EPDM without pre-treatment, while ensuring reliable high performance, without compromising competitiveness.

Our tesa® ACXplus Primerless 790xx is the solution you have been waiting for.

Performance you can trust — backed by real-world testing

Even in demanding production conditions, tesa® ACXplus Primerless delivers. Our bonding solution was evaluated under realistic scenarios to prove its performance:

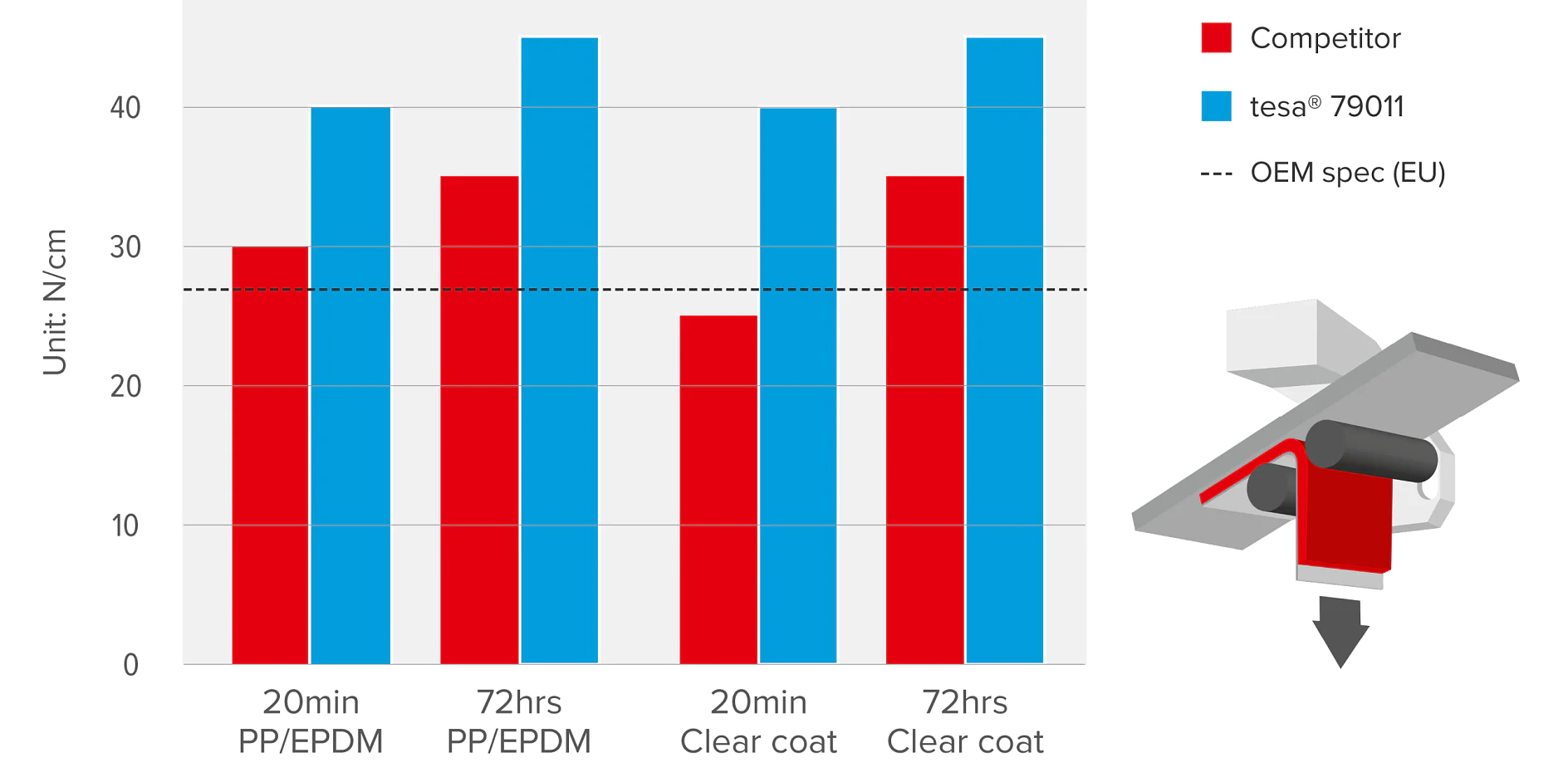

Floating roller peel test

After only 20 minutes of dwell time, tesa® ACXplus 790xx achieved over 90% of its final peel strength. This performance was consistent across both PP/EPDM and various OEM clear coat substrates, thanks to its rapid wetting capability.

For production environments where cycle times are tight, this fast bonding response helps reduce wait times and supports streamlined processes without sacrificing reliability.

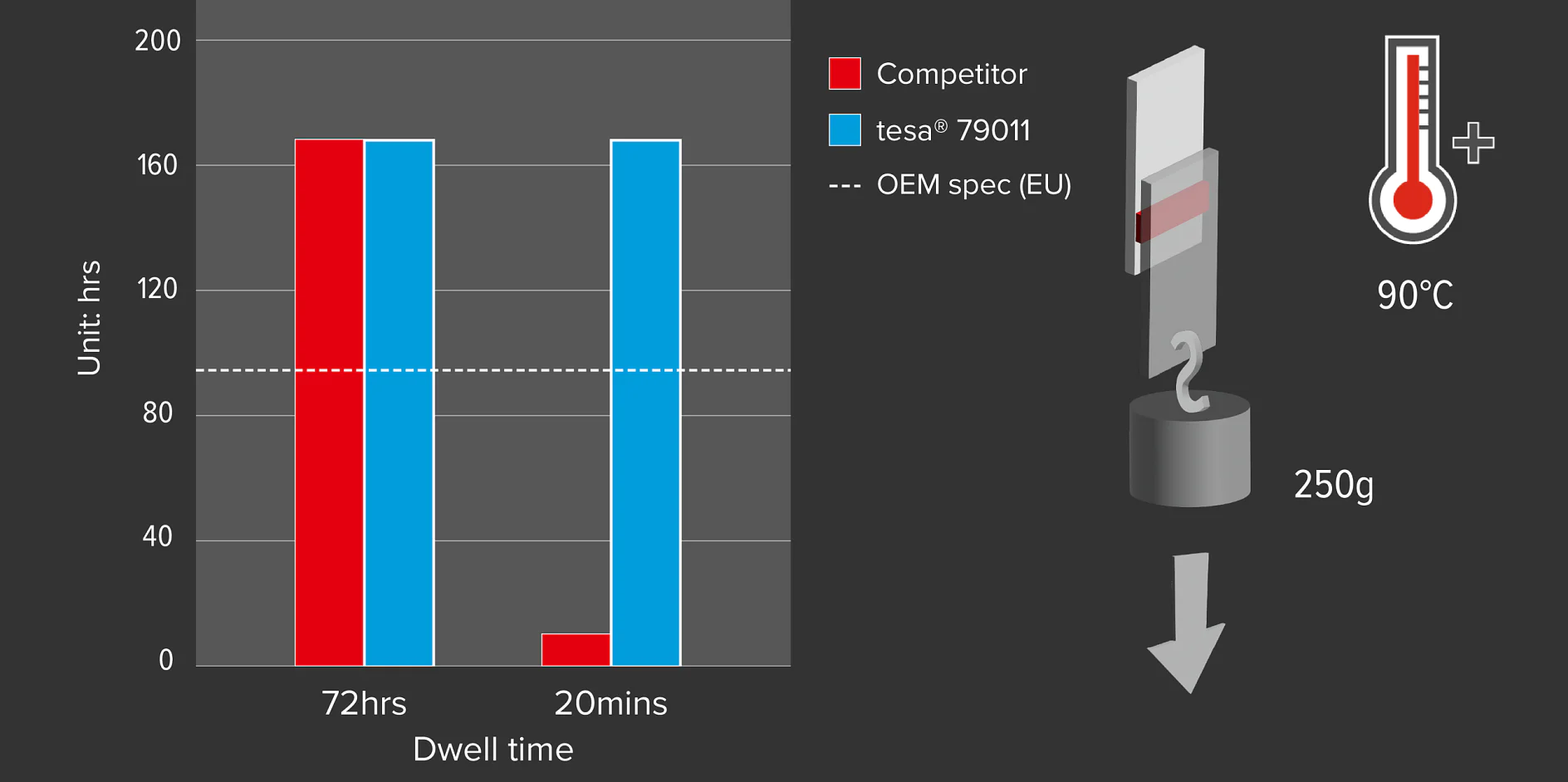

Static shear test

In our high-temperature static shear test, tesa® ACXplus 790xx held a 250 g/cm² load at 90°C — even after only 20 minutes of dwell time. Where competitive tapes began to fail, 790xx maintained secure bonding under thermal stress.

This reliable performance supports fast-paced production with minimal dwell, reducing the risk of rework and ensuring dependable adhesion in extreme conditions.

These tests confirm:

tesa® ACXplus 790xx delivers high bonding performance even under short dwell conditions — achieving results in just 20 minutes that typically require 72 hours. It’s a game-changer for fast-paced automotive production.

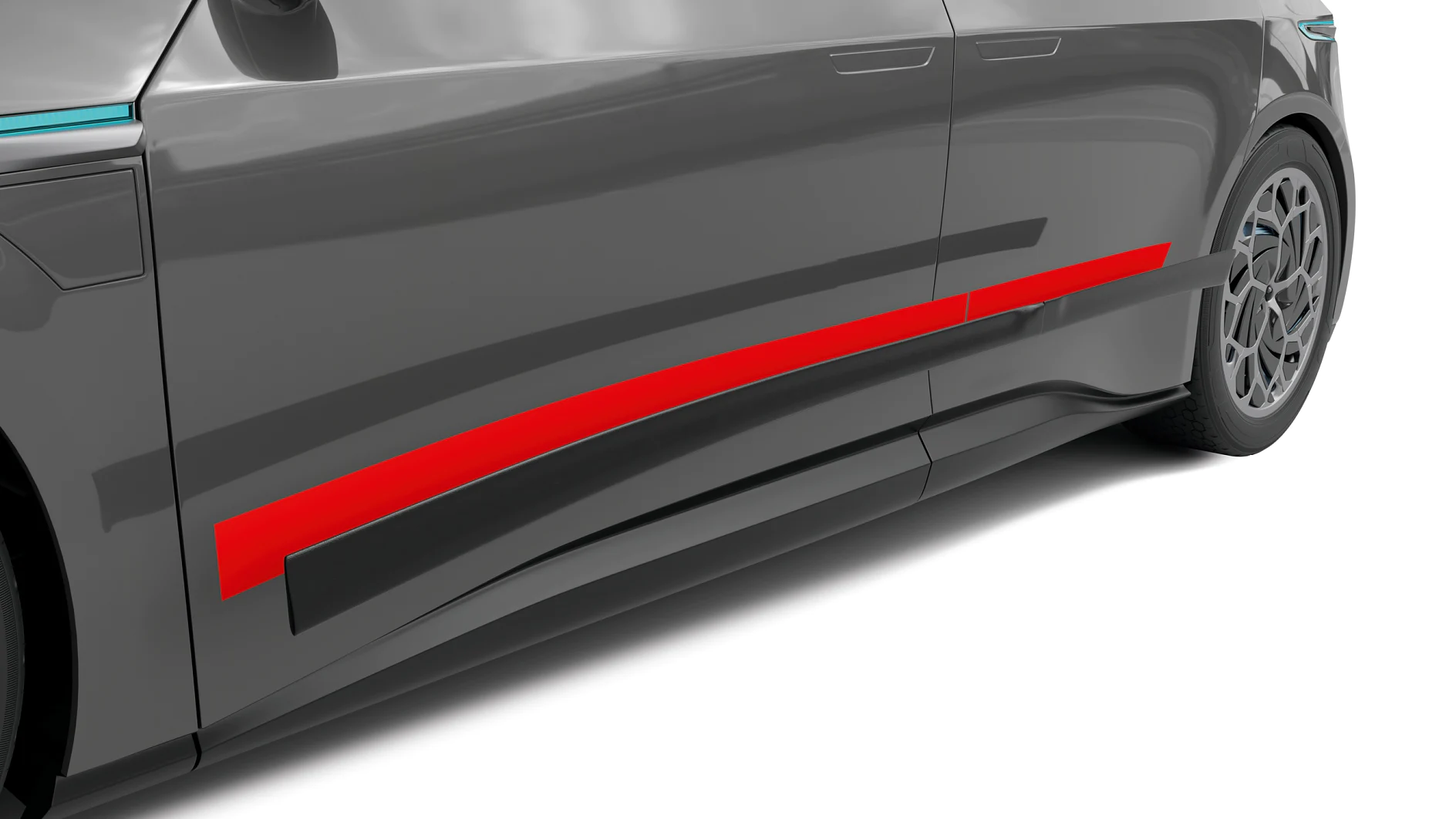

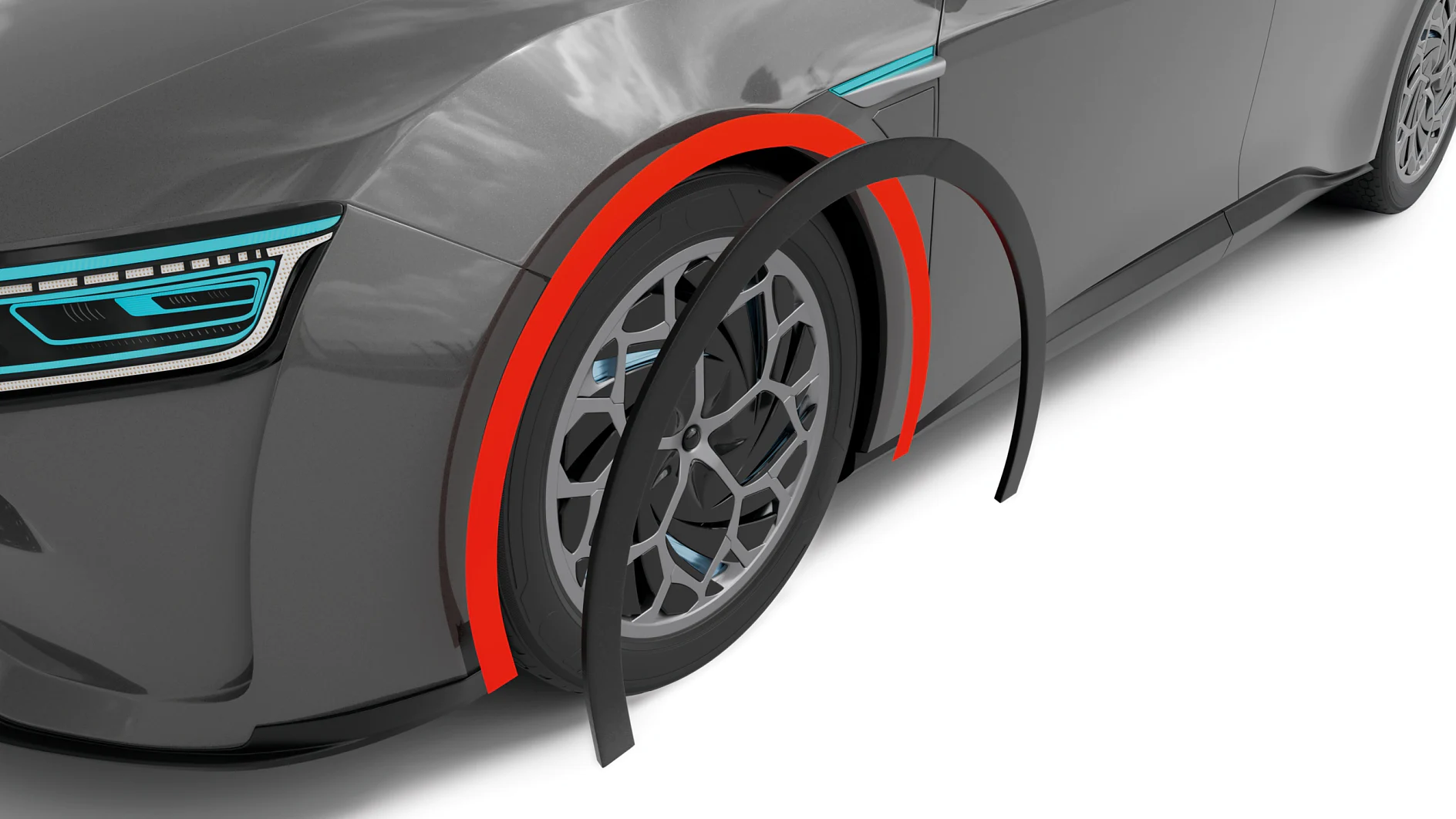

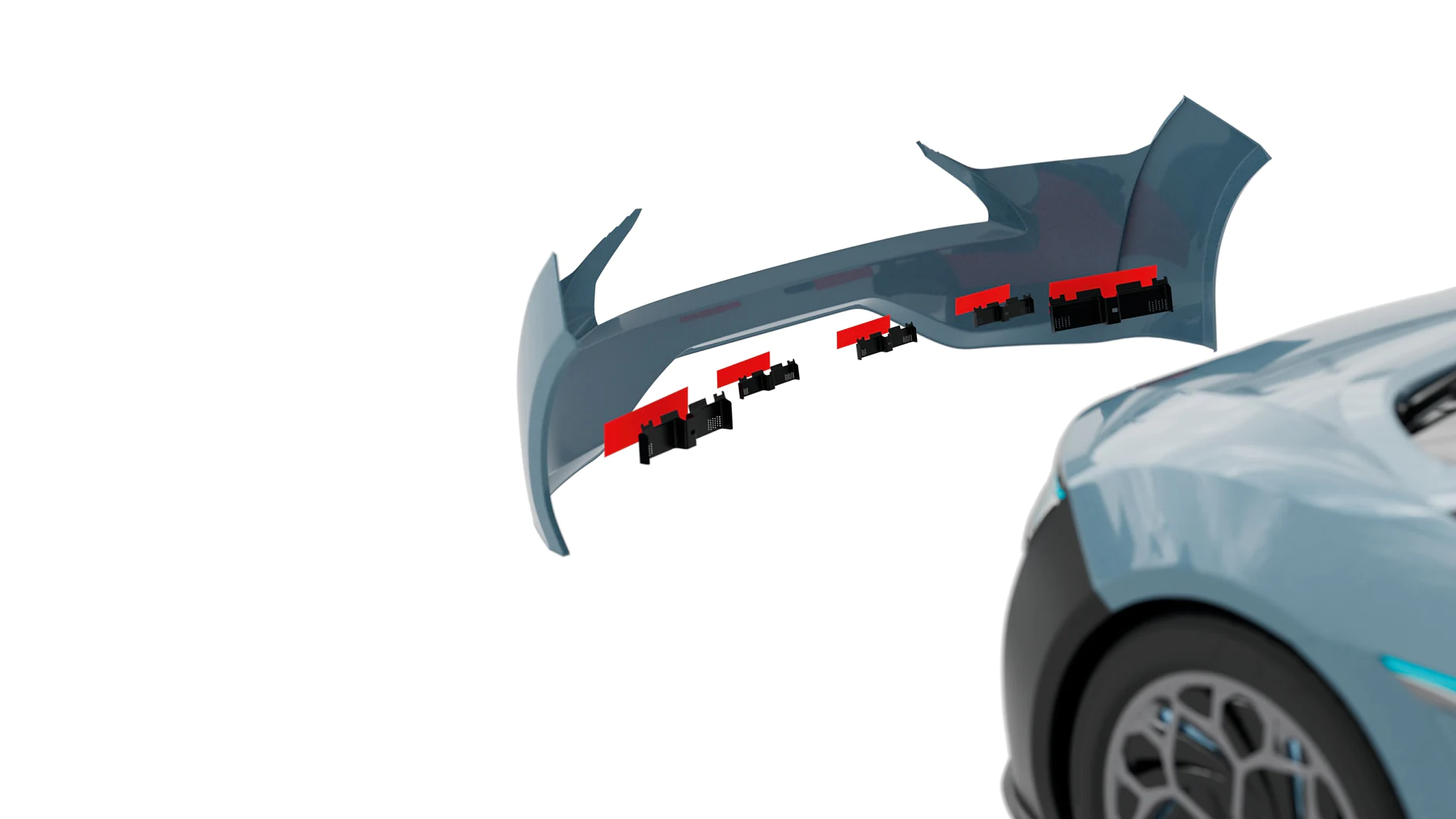

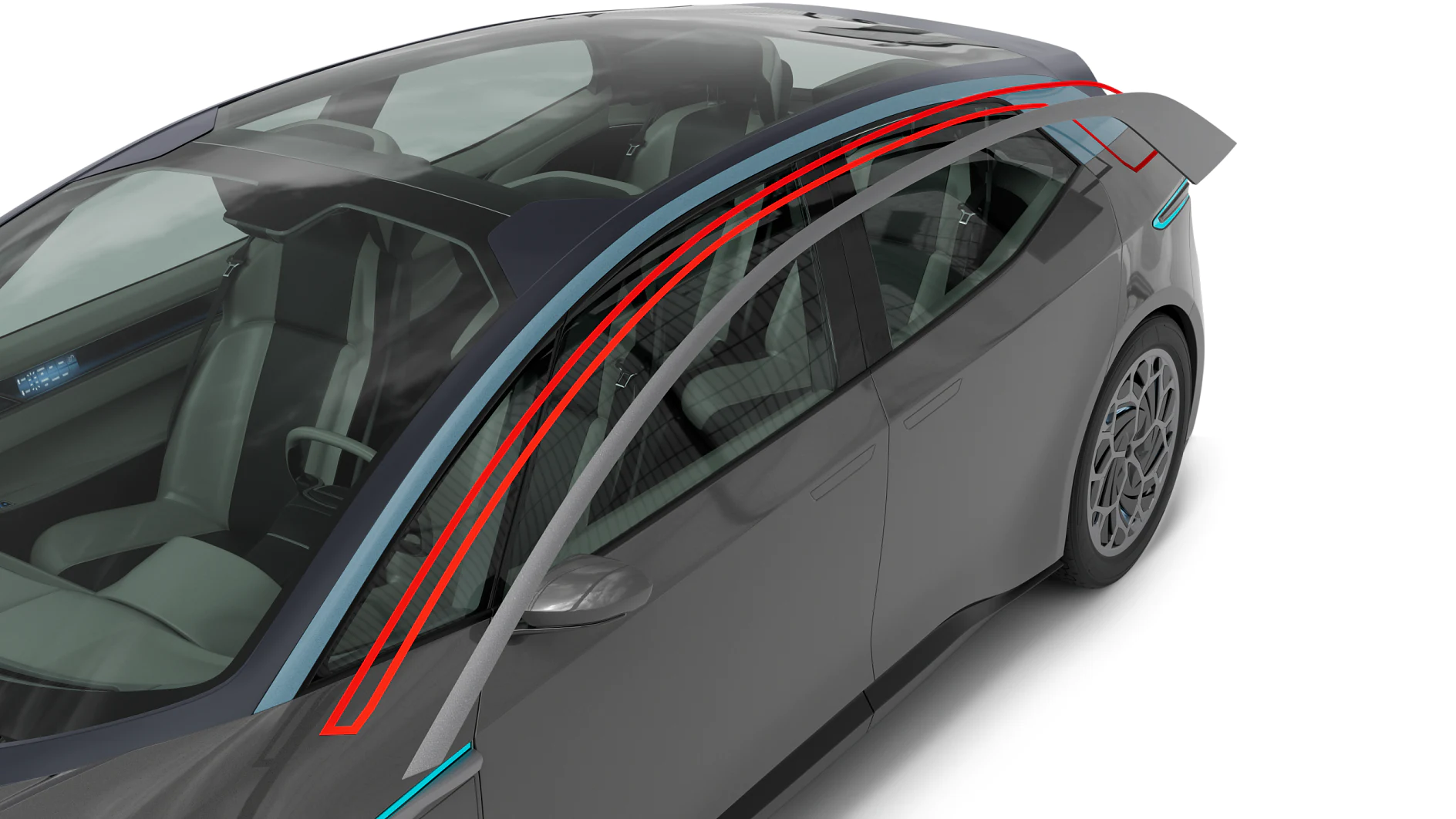

Want to see practical examples?

Explore where and how 790xx is used across the vehicle.

Flexible formats. Easy integration.

No two production lines are alike. That’s why tesa® ACXplus Primerless is offered in a full range of formats — designed to match your process, no matter how it’s set up.

Whether you apply tape by hand or with a fully automated line, 790xx adapts to your needs:

- Spool format for high-volume automated application (up to 1,800 m)

- Log rolls in various widths for flexible conversion

- Pancake rolls for semi-automated or manual use

- Die-cuts supplied by global tesa converting partners

Our dedicated technical teams and Customer Solution Centers across Asia, Europe, and the Americas support smooth integration — from selecting the right tape to application trials and automation equipment setup.