Double-sided tapes

developed for your

manufacturing needs

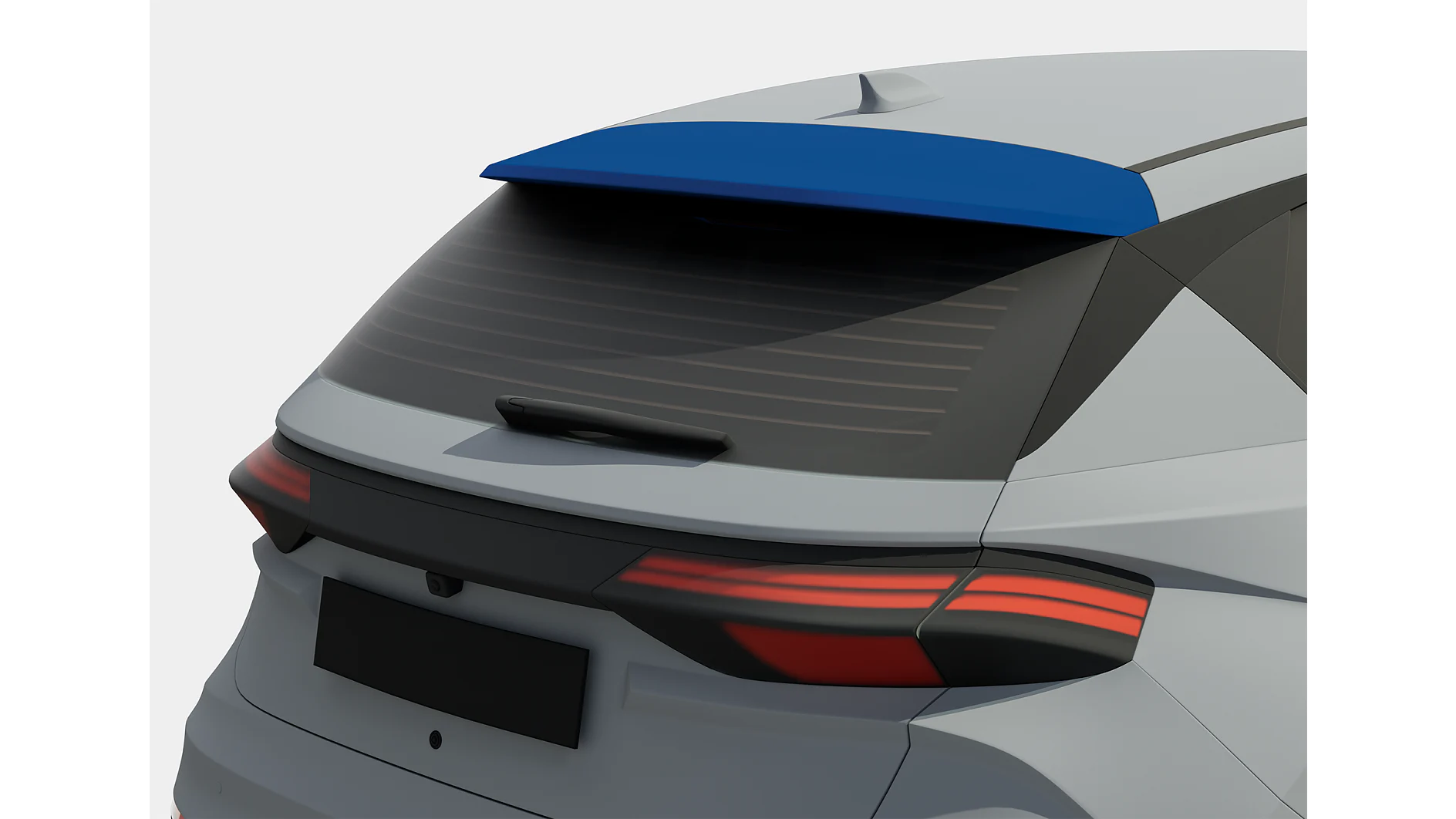

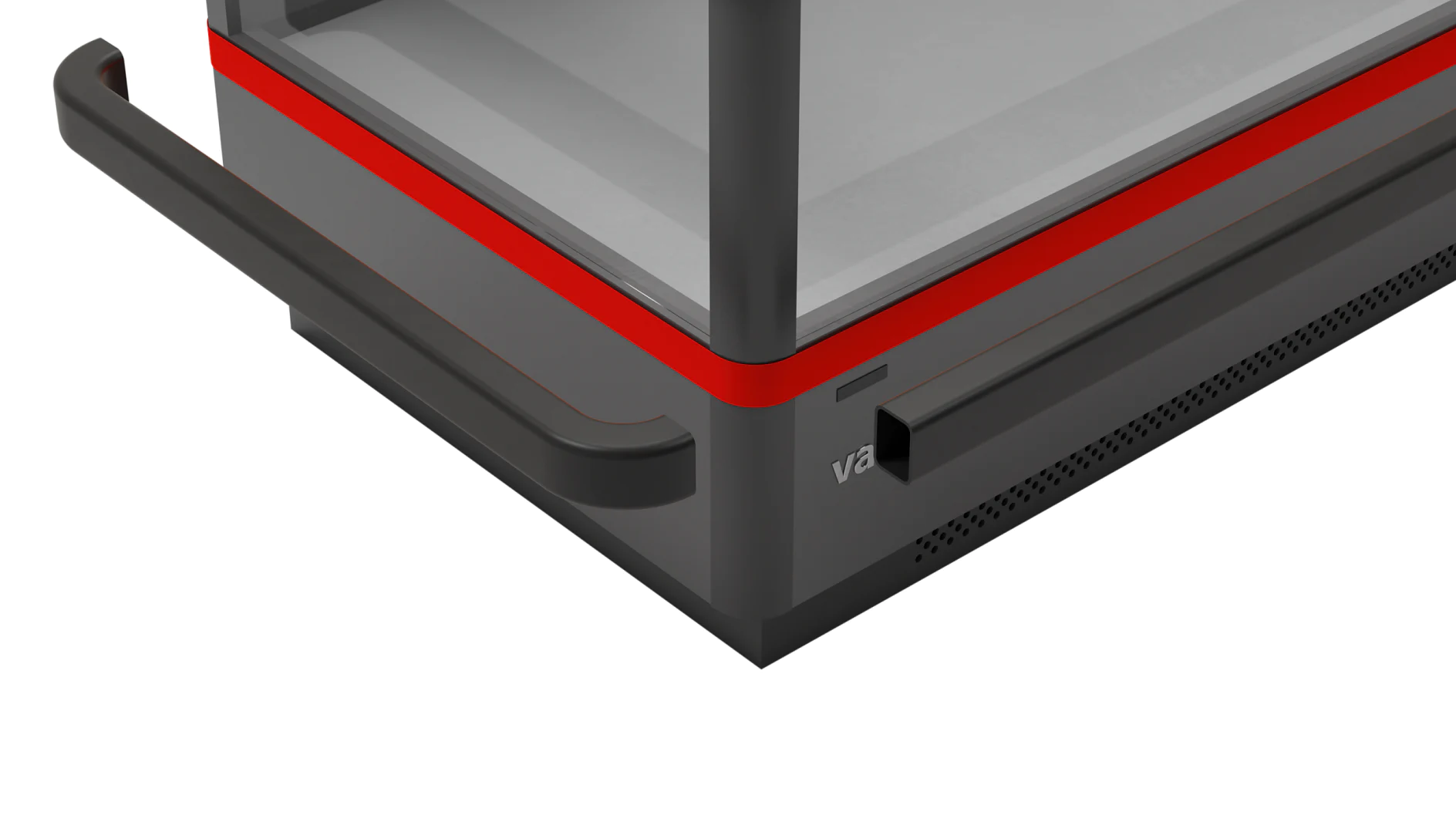

With a strong adhesive surface on either side, double-sided tapes offer a viable alternative to liquid adhesives or traditional fastenings such as screws, riverting, nuts, and bolts, giving a smooth, flawless finish. Double-sided tapes enable simplified production processes in many sectors, allowing manufacturers to bond components quickly and cleanly - to both smooth and rough surfaces -, such as mounting batteries, lenses, and touch panels as well as sensors and components.

At tesa, we have developed a range of double-sided tapes that meet the demanding needs of our corporate customers. Our high-performance double-sided tapes for general applications range from film and foam tapes, structural bonding tapes, to removable double-sided tapes. And if you’re looking for specialist functionality,we at tesa offer grounding and electrically conductive, waterproof, as well as thermal management tapes for a variety of purposes.

Features of double-sided tapes

Double-sided tapes are a versatile and useful adhesive solution that can be used in a variety of applications. They are designed to stick two surfaces together with a strong bond that is resistant to separation. Double-sided tapes come in a wide range of types and styles, each with its own unique features and benefits. In this list, we will explore some of the key features of double-sided tapes.

Getting the best from double sided tape

Bonding can be a challenge in almost every industry in situations where different materials need to be bonded. In addition, modern design concepts require high-tech materials to be bonded without affecting their special structures or properties. This is where double-sided adhesive tapes solve common mounting and fixing issues found in many production processes.

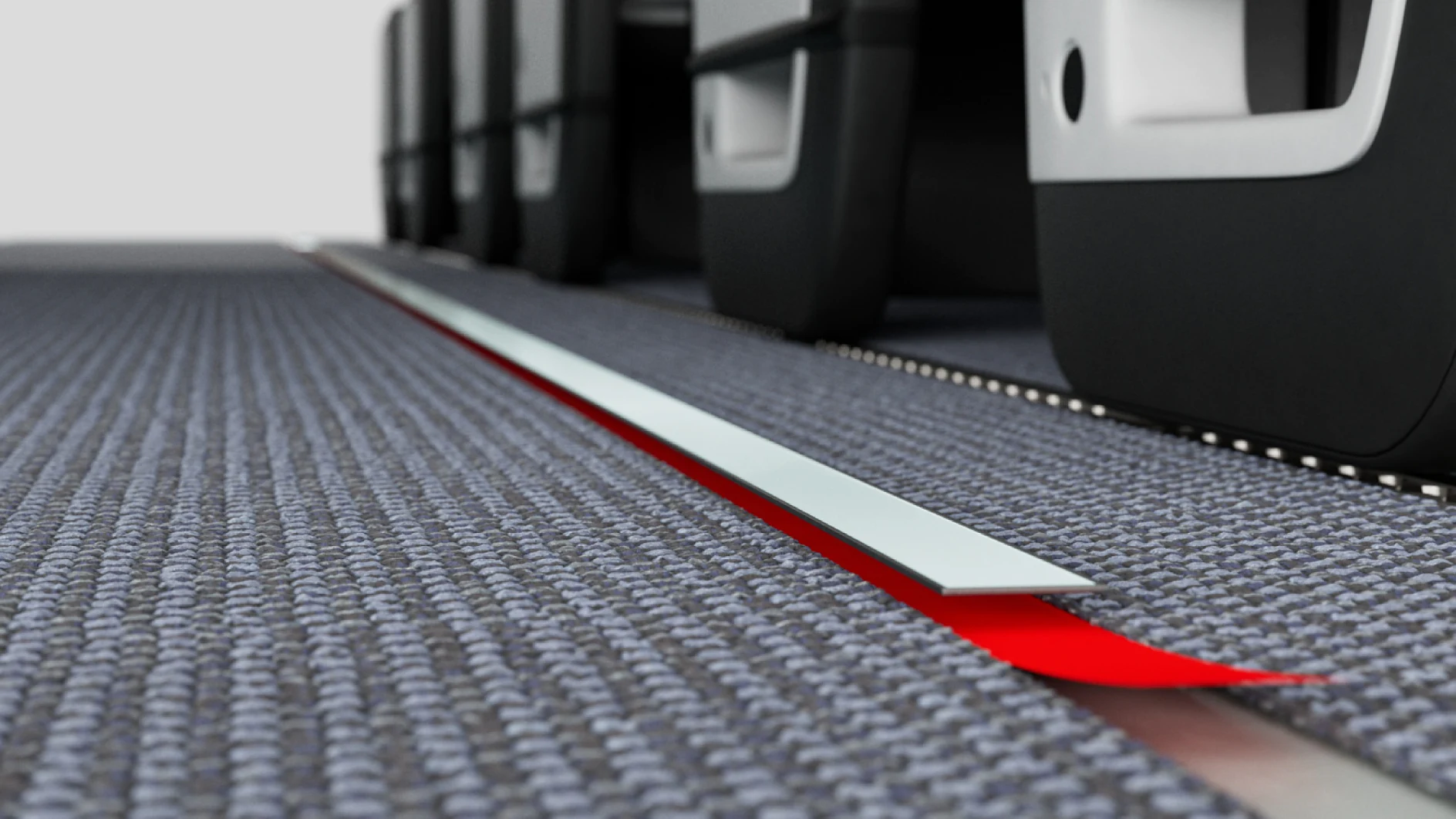

When bonding two surfaces using a double-sided tape, one side of the tape is positioned and fixed onto a surface A applying pressure. Once in place, the release liner of the tape is removed, and the surface B can be placed onto the open side of the tape and pressed into place with force being attached equally to ensure a good fit.

When a smaller object is being placed onto a flat surface, it is normally more effective to first attach the tape to the item being stuck in place. This reduces the amount of tape that needs to be used and helps to ensure that the item is positioned correctly.

Potential industrial applications for double-sided tapes

Double-sided tapes are a popular choice in industrial applications due to their unique features and benefits. They offer a strong and reliable bond that can withstand harsh environments and extreme temperatures. Industrial-grade double-sided tapes are designed to provide long-lasting adhesion, making them ideal for use in demanding applications such as automotive, electronics, appliances, building components, and aerospace industries.

Overview of double-sided tapes

The range of our double-sided tapes offers proven reliability and high-performance adhesion that meet the demands of manufacturers worldwide. However, we recognize every project is unique and has specific requirements. That’s why our experts are happy to develop bespoke solutions with you and help, find the right adhesive solution for your specific use case. Find an overview of our double-sided tape solutions below:

Double Sided Tapes: FAQ

What is an adhesive tape carrier, and do all double-sided tapes have one?

A carrier is a thin backing on which the adhesive is spread. This carrier could be made of one of several materials: paper, film, fabric, acrylic foam, foil, or non-woven fibers. All double-sided tapes have a carrier which also helps further strengthen the bond. The choice of double-sided tape with a specific carrier depends on the application as each material brings particular properties to the tape.

What is the difference between a double-sided tape and an adhesive transfer tape?

Double-sided tape has adhesive on both sides of a carrier, allowing each surface to bond securely to the tape. The tape’s carrier also provides additional structural support. Adhesive transfer tape, however, has no carrier and just relies on the strength of the adhesive to form a bond. In return it offers an increased conformability and wetting performance.

Why choose a double-sided tape for industrial applications?

Our extensive track record has allowed the experts at tesa to test our adhesive tapes against other types of bonding systems over many years. And based on our experience, the advantages of double-sided tapes are clear when meeting the challenges of today’s complex, optimized production processes. For example, double-sided tapes can greatly reduce common health risks related to liquid glue solutions and can be easier to handle. Moreover, double-sided tapes can even carry more weight than using regular screws in certain scenarios and provide more design freedom in manufacturing processes.

What are the advantages of double-sided tape?

Double-sided tapes are used in many applications in a range of industries. Some are ideal for bonding to flat smooth surfaces such as glass, metal, and non-embossed plastics. Others are ideal for rough, irregular surfaces. All tapes generally offer a good temperature resistance, and they are easily integrated into current production lines. Double-sided tapes can absorb shocks and vibrations and are relatively easy to remove, if needed.

How can double-sided tape be removed?

tesa® double-sided adhesive tapes provide strong hold on various surfaces, even for heavy duty applications. Many of our products can be removed easily and without leaving any residue, when needed. Over the last decades we have developed a broad range of double-sided tapes that can be debonded in different ways, e.g. by peeling, by applying solvents or by stretching (tesa® Bond & Detach). As debonding is becoming increasingly important we are constantly developing new methods. Please contact us to learn more.