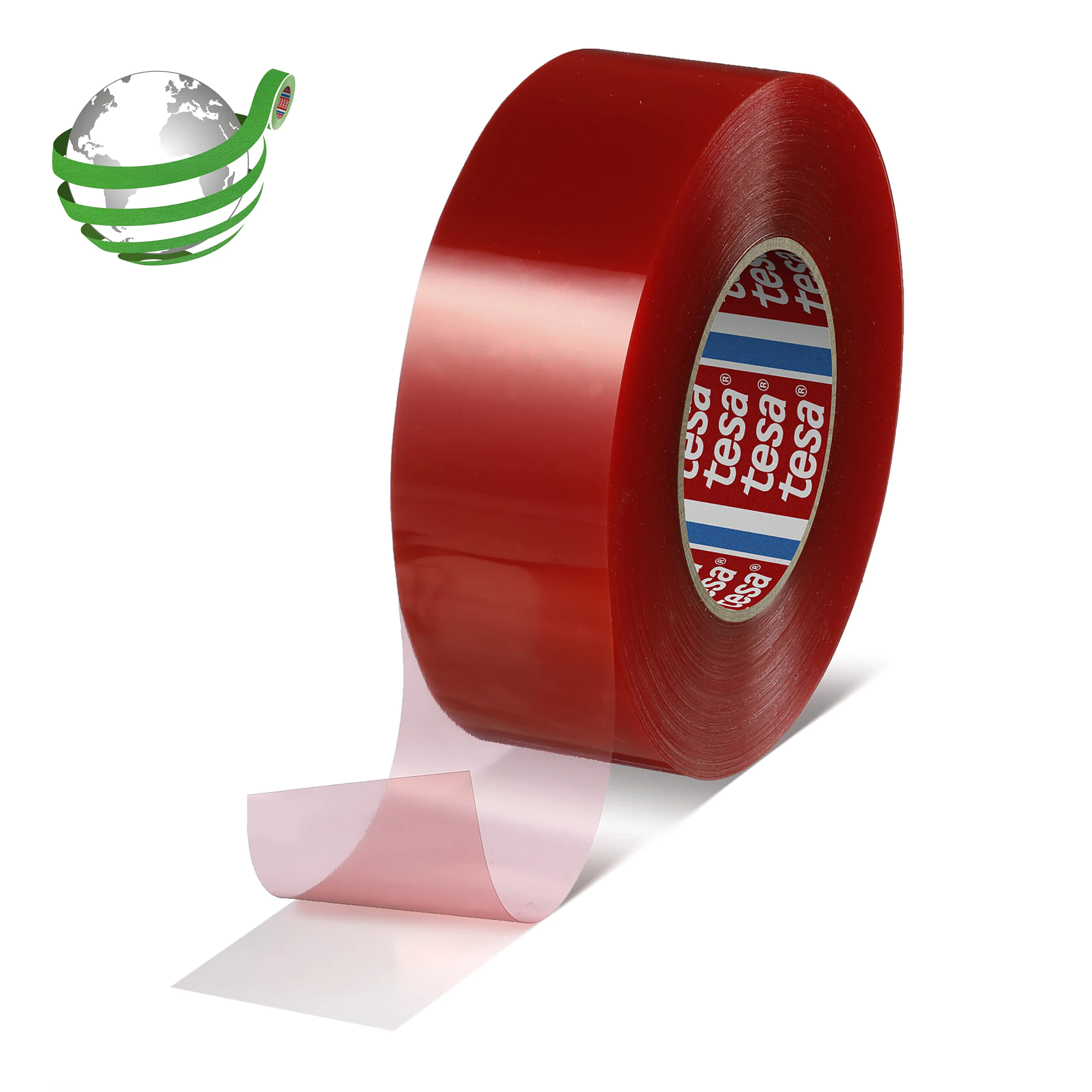

tesa® 51903

86µm double sided transparent PVC film tape without liner

Product Features

- Double-sided tape without liner

- Different adhesion values on each side

- Adhesive on each side is precisely balanced, so that tesa® 51903 can be unwound without liner

Product description

tesa® 51903 is a transparent, double-sided adhesive tape without release liner featuring a PVC backing and an acrylic adhesive. The acrylic adhesive system of the double-sided linerless tape has different adhesion values on each side, which makes tesa® 51903 the perfect solution for box-closure applications. The different adhesion values on each side are precisely balanced, so that tesa® 51903 can be unwound easily, even after long periods of storage.

Product details and specifications

Product Features

- Double-sided tape without liner

- Different adhesion values on each side

- Adhesive on each side is precisely balanced, so that tesa® 51903 can be unwound without liner

Application Fields

- tesa® 51903 is ideally used for box-closure applications and is even suited for thin film bags

- Mounting lightweight parts

- Splicing various materials such as plastic, metal foils, paper, and cardboard

- Bonding applications in the lithography industry

Product Construction

| Backing material | PVC film |

|---|---|

| Color | transparent |

| Total thickness | 86 µm |

| Type of adhesive | acrylic |

Product Construction

| Backing material | PVC film |

|---|---|

| Color | transparent |

| Total thickness | 86 µm |

| Type of adhesive | acrylic |

Properties / Performance Values

| Elongation at break | 40 % |

|---|---|

| Tensile strength | 35 N/cm |

| Softener resistance | low |

| Static shear resistance at 40°C | low |

| Temperature resistance min. | -40 °C |

| Static shear resistance at 23°C | low |

| Chemical resistance | medium |

| Ageing resistance (UV) | very good |

| Temperature resistance long term | 60 °C |

| Tack | good |

| Temperature resistance short term | 70 °C |

| Humidity resistance | very good |

Properties / Performance Values

| Elongation at break | 40 % |

|---|---|

| Tensile strength | 35 N/cm |

| Softener resistance | low |

| Static shear resistance at 40°C | low |

| Temperature resistance min. | -40 °C |

| Static shear resistance at 23°C | low |

| Chemical resistance | medium |

| Ageing resistance (UV) | very good |

| Temperature resistance long term | 60 °C |

| Tack | good |

| Temperature resistance short term | 70 °C |

| Humidity resistance | very good |

Adhesion to Values

| Adhesion to ABS (initial) | 2.8 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) | 2 N/cm |

| Adhesion to Aluminium (initial) | 1.5 N/cm |

| Adhesion to Aluminium (after 14 days) | 2.5 N/cm |

| Adhesion to PC (initial) | 2.7 N/cm |

| Adhesion to PC (after 14 days) | 1.8 N/cm |

| Adhesion to PE (initial) | 1.2 N/cm |

| Adhesion to PE (after 14 days) | 1.8 N/cm |

| Adhesion to PET (initial) | 1.8 N/cm |

| Adhesion to PET (after 14 days) | 2.2 N/cm |

| Adhesion to PP (initial) | 1.7 N/cm |

| Adhesion to PP (after 14 days) | 2.4 N/cm |

| Adhesion to PS (initial) | 2.7 N/cm |

| Adhesion to PS (after 14 days) | 2.7 N/cm |

| Adhesion to PVC (initial) | 1.8 N/cm |

| Adhesion to PVC (after 14 days) | 2.5 N/cm |

| Adhesion to Steel (initial) | 2.4 N/cm |

| Adhesion to Steel (after 14 days) | 3 N/cm |

Adhesion to Values

| Adhesion to ABS (initial) | 2.8 N/cm |

|---|---|

| Adhesion to ABS (after 14 days) | 2 N/cm |

| Adhesion to Aluminium (initial) | 1.5 N/cm |

| Adhesion to Aluminium (after 14 days) | 2.5 N/cm |

| Adhesion to PC (initial) | 2.7 N/cm |

| Adhesion to PC (after 14 days) | 1.8 N/cm |

| Adhesion to PE (initial) | 1.2 N/cm |

| Adhesion to PE (after 14 days) | 1.8 N/cm |

| Adhesion to PET (initial) | 1.8 N/cm |

| Adhesion to PET (after 14 days) | 2.2 N/cm |

| Adhesion to PP (initial) | 1.7 N/cm |

| Adhesion to PP (after 14 days) | 2.4 N/cm |

| Adhesion to PS (initial) | 2.7 N/cm |

| Adhesion to PS (after 14 days) | 2.7 N/cm |

| Adhesion to PVC (initial) | 1.8 N/cm |

| Adhesion to PVC (after 14 days) | 2.5 N/cm |

| Adhesion to Steel (initial) | 2.4 N/cm |

| Adhesion to Steel (after 14 days) | 3 N/cm |

tesa® products prove their impressive quality day in, day out in demanding conditions and are regularly subjected to strict controls. All technical information and data above mentioned are provided to the best of our knowledge on the basis of our practical experience. They shall be considered as average values and are not appropriate for a specification. Therefore tesa SE can make no warranties, expressed or implied, including, but not limited to any implied warranty of merchantability or fitness for a particular purpose. The user is responsible for determining whether the tesa® product is fit for a particular purpose and suitable for the user’s method of application. If you are in any doubt, our technical staff will be glad to support you.

Downloads

Download the files below for more technical details and information on this product.