Additional Info

Technical recommendations:

tesa® LTC is not self-adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

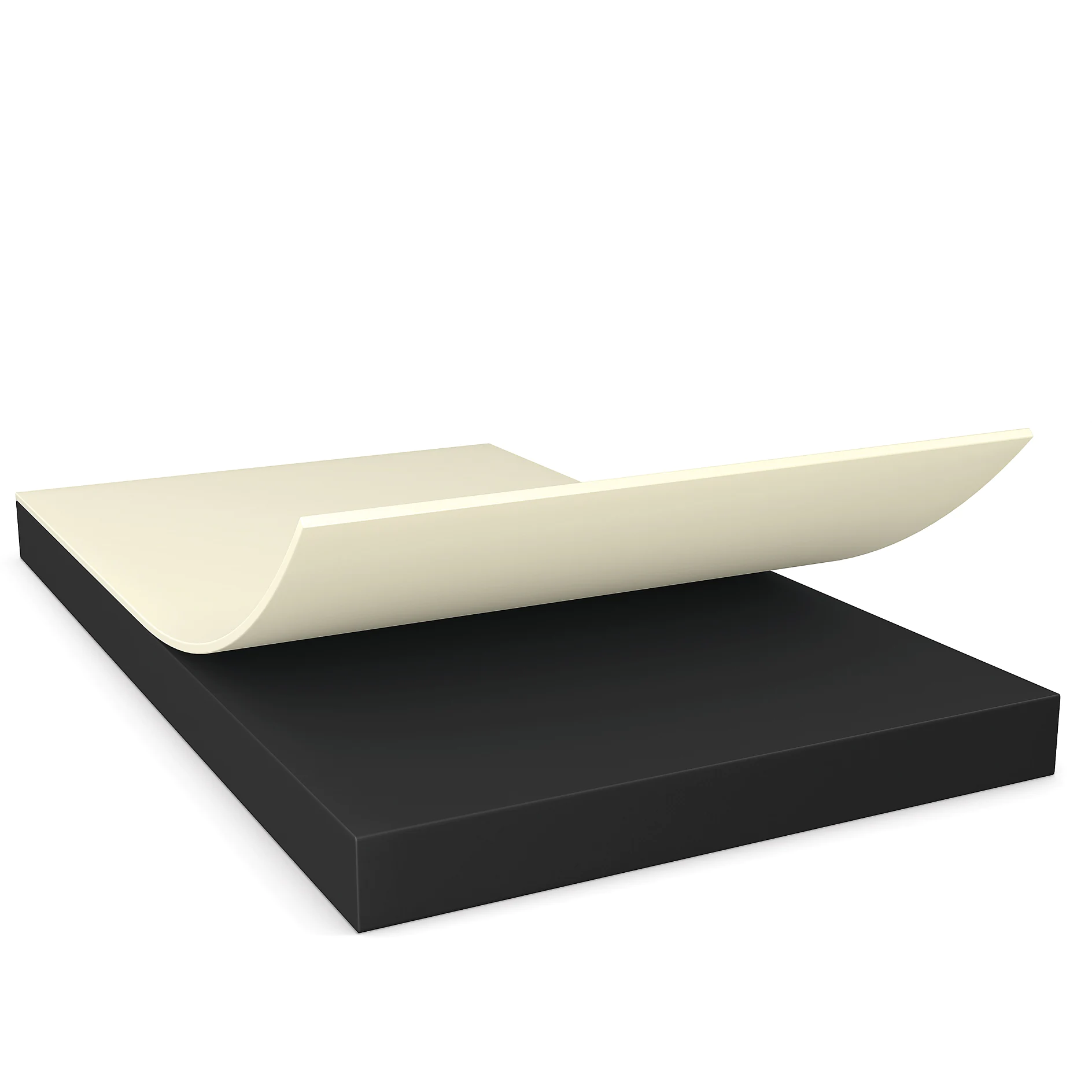

1) Pre-lamination

During pre-lamination, laminate the film onto the first component. Setting:

Short-time exposure to 60°C bond line temperature during pre-lamination does not impact final bonding potential.

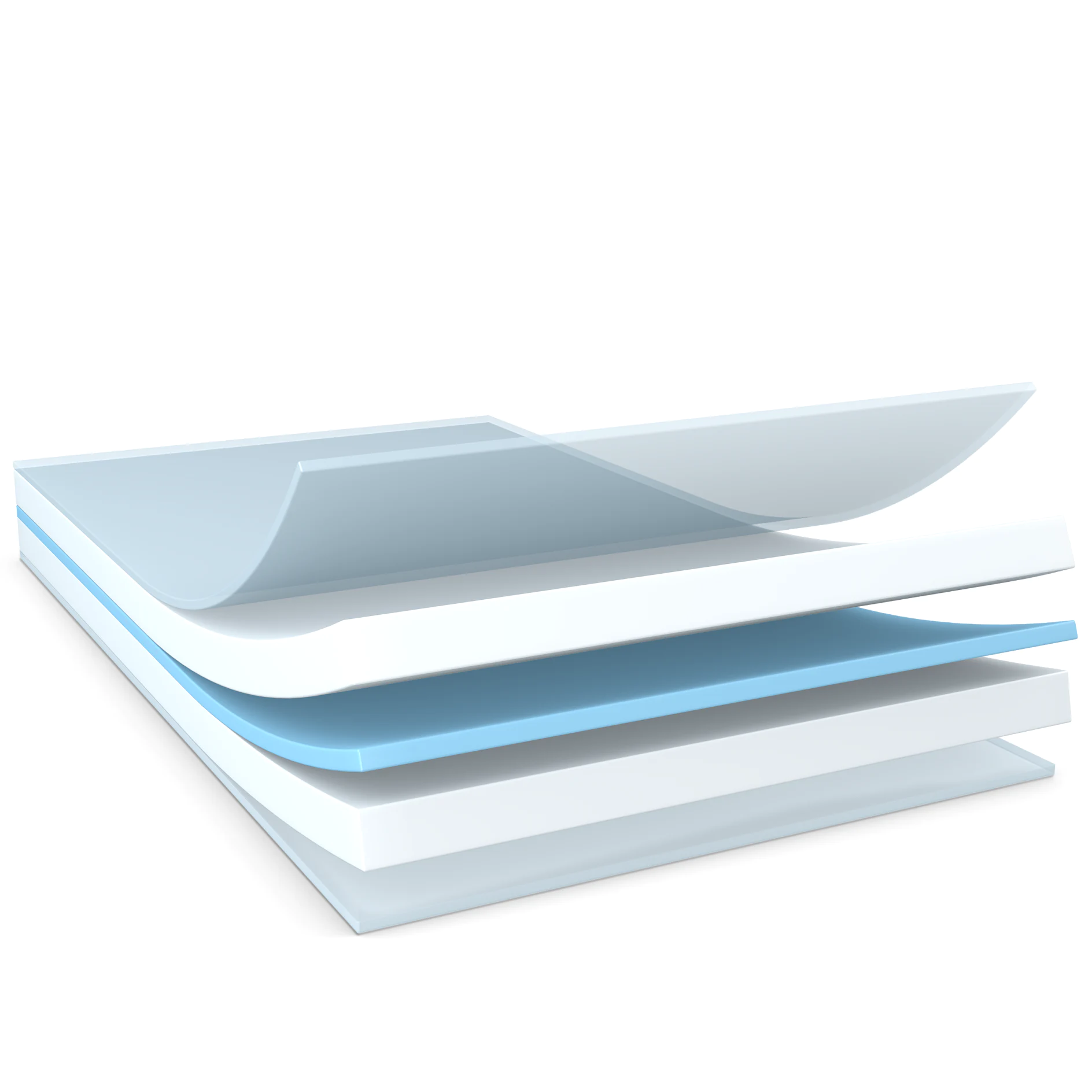

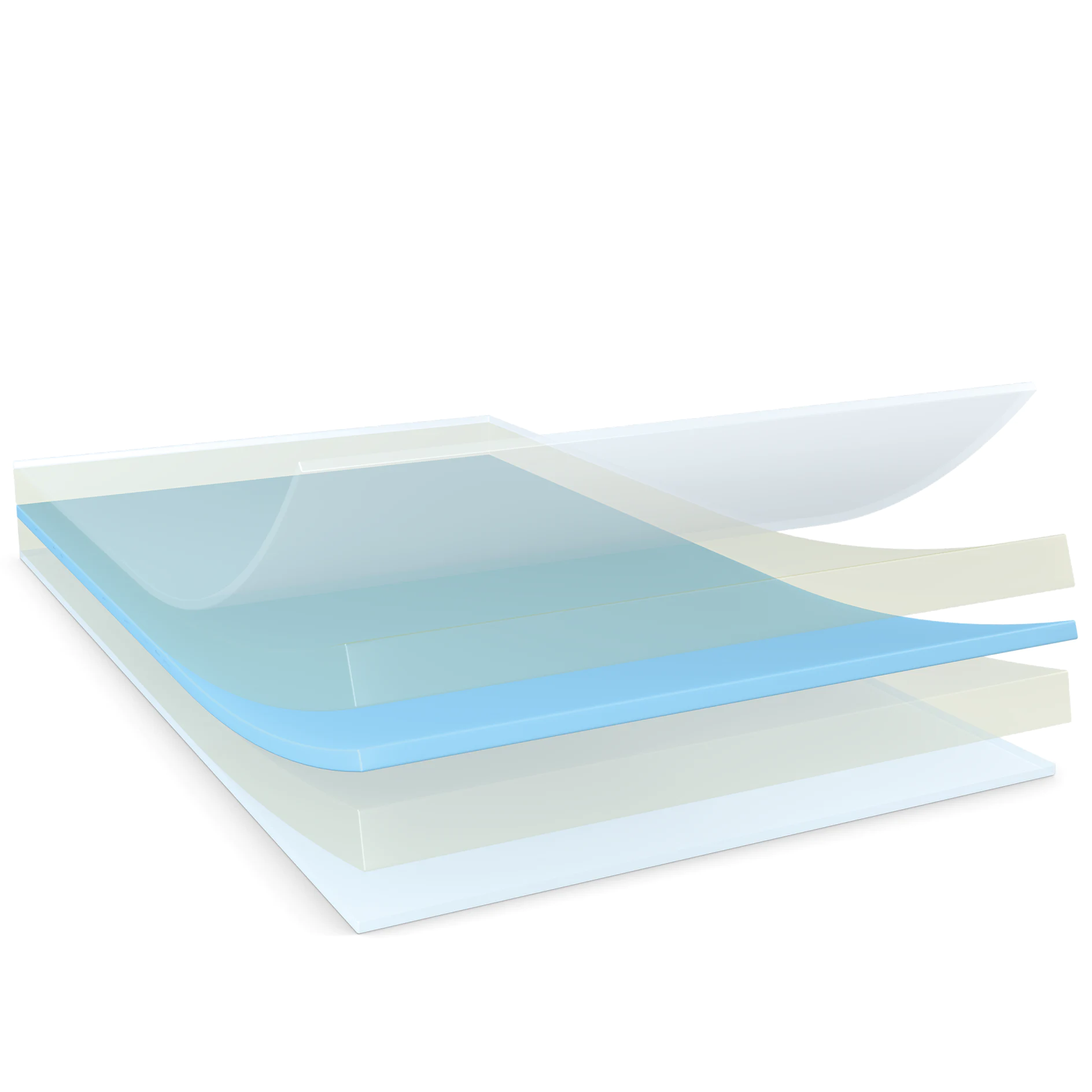

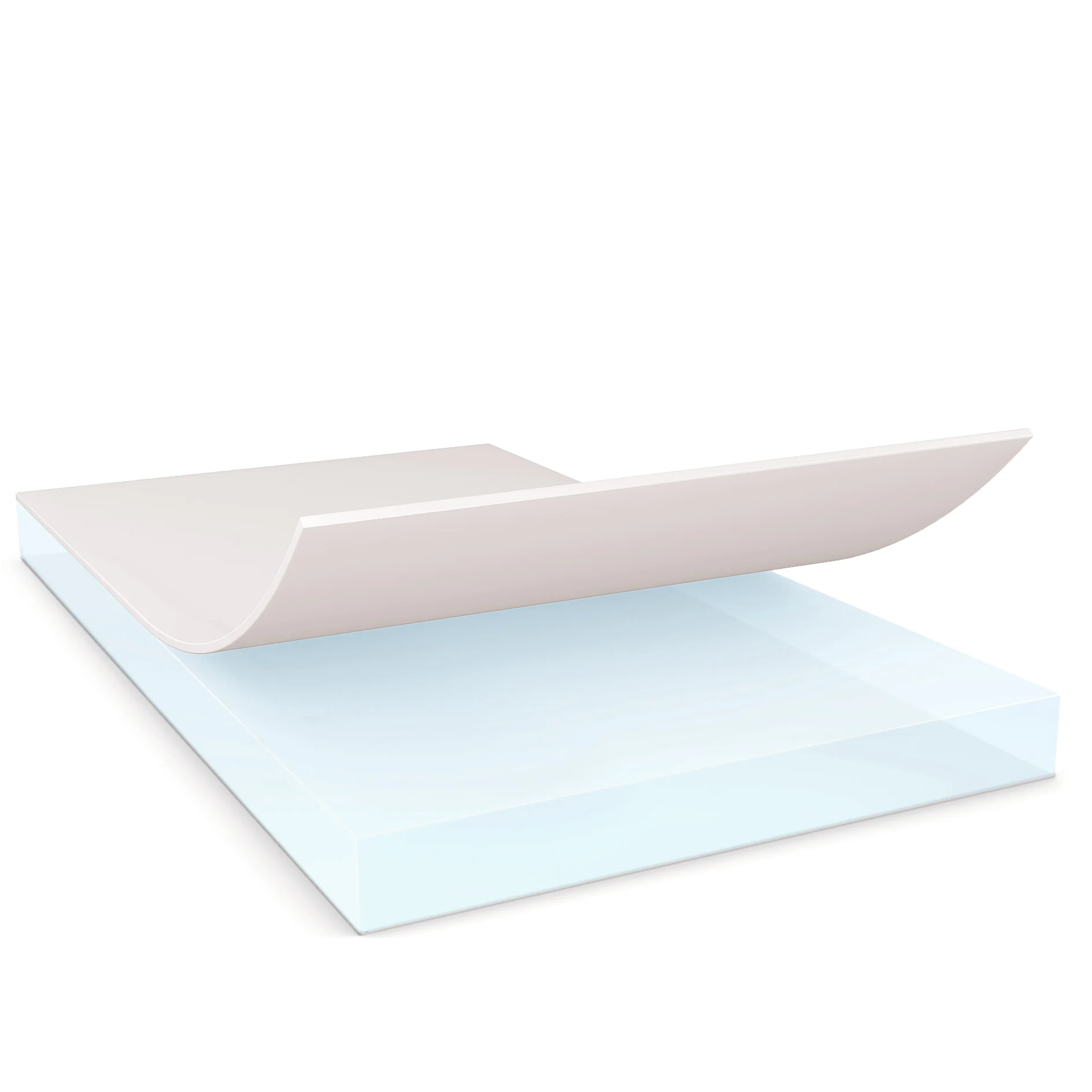

2) Bonding

Remove the liner from the film after the pre-lamination step. Position the second component. Apply temperature and pressure for the bonding time to reach sufficient bonding strength. Setting:

Short cycle times can be achieved at 110 °C bond line temperature. For activation at lower temperatures, increase the heat-press time or combine a short heat-press step with oven curing.

Bonding strength values were obtained under standard laboratory conditions (Material: PC/PC; bonding conditions: temperature = 90 °C; pressure = 10 bar; time = 300 sec).

To reach maximum bonding strength, surfaces should be clean and dry. Allow at least 1-2 hours dwell-time after bonding before performance testing. Final bonding strength will be reached after 24 hours.

Storage

¹ ‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line. ² ‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transferred from jig surface directly to the bonding area.

tesa® LTC is not self-adhesive. It is activated by heat and pressure over a certain interval. The following values are recommendations for bond line parameters to start with.

1) Pre-lamination

During pre-lamination, laminate the film onto the first component. Setting:

- Temperature¹ 50-60 °C

- Pressure² 1-5 bar

- Time 5 – 20 s

Short-time exposure to 60°C bond line temperature during pre-lamination does not impact final bonding potential.

2) Bonding

Remove the liner from the film after the pre-lamination step. Position the second component. Apply temperature and pressure for the bonding time to reach sufficient bonding strength. Setting:

- Temperature¹ 75 – 110 °C

- Pressure² 5 – 10 bar

- Time 10 – 480 s

Short cycle times can be achieved at 110 °C bond line temperature. For activation at lower temperatures, increase the heat-press time or combine a short heat-press step with oven curing.

Bonding strength values were obtained under standard laboratory conditions (Material: PC/PC; bonding conditions: temperature = 90 °C; pressure = 10 bar; time = 300 sec).

To reach maximum bonding strength, surfaces should be clean and dry. Allow at least 1-2 hours dwell-time after bonding before performance testing. Final bonding strength will be reached after 24 hours.

Storage

- tesa recommends storage in original packaging in cool and dry conditions.

- tesa® LTC should not be exposed to more than 35°C at any time before bonding (during transport, storage and converting). Long term storage should remain below 25°C.

- The shelf life is 9 months after production. For the actual shelf life please refer to the best before date on the label in the log roll core.

- More details are available in our transportation guideline.

¹ ‘Pre-lamination’ and ‘Bonding’ temperature refer to the data that is measured in the bond line. ² ‘Pre-lamination’ and ‘Bonding’ pressure refer to the force that is transferred from jig surface directly to the bonding area.