Additional Info

tesa® L-tape is a reactive adhesive. It is activated by light at a wavelength of 365 nm or 460 nm. tesa® L-tape can be used for bonding of translucent or opaque substrates.

Bonding of opaque substrates

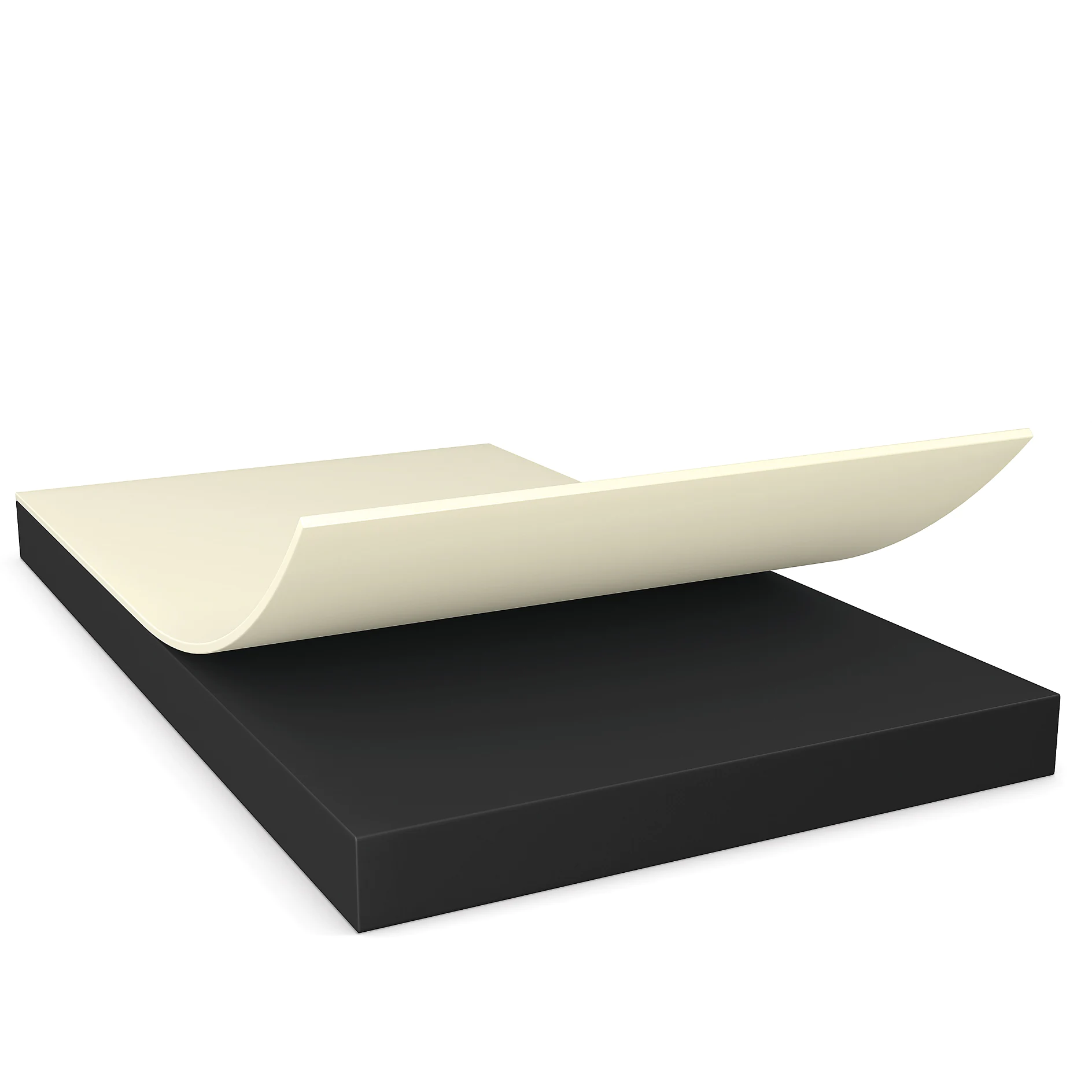

The open time of tesa® L-tape enables the bonding of opaque substrates like plastics and metals. tesa® L-tape can be activated by light as an die-cut or already pre-laminated onto the first substrate.

Activation of pre-laminated parts: First remove the covering liner of tesa® L-tape and pre-laminate the tape onto the first substrate. The pre-laminated parts are then exposed to light. The second substrate is bonded by applying sufficient pressure (≥3 bar) within 5 min after activation.

Activation of die-cuts: First the die-cut of tesa® L-tape is activated by light. The covering liner of the die-cut must be light-permeable (e.g., clear PET) to enable the activation of the tape. After activation the die-cut is pre-laminated onto the first substrate. The second substrate is then bonded by applying sufficient pressure (≥3 bar). Pre-lamination and bonding must take place within 5 min after activation.

Bonding of translucent substrates

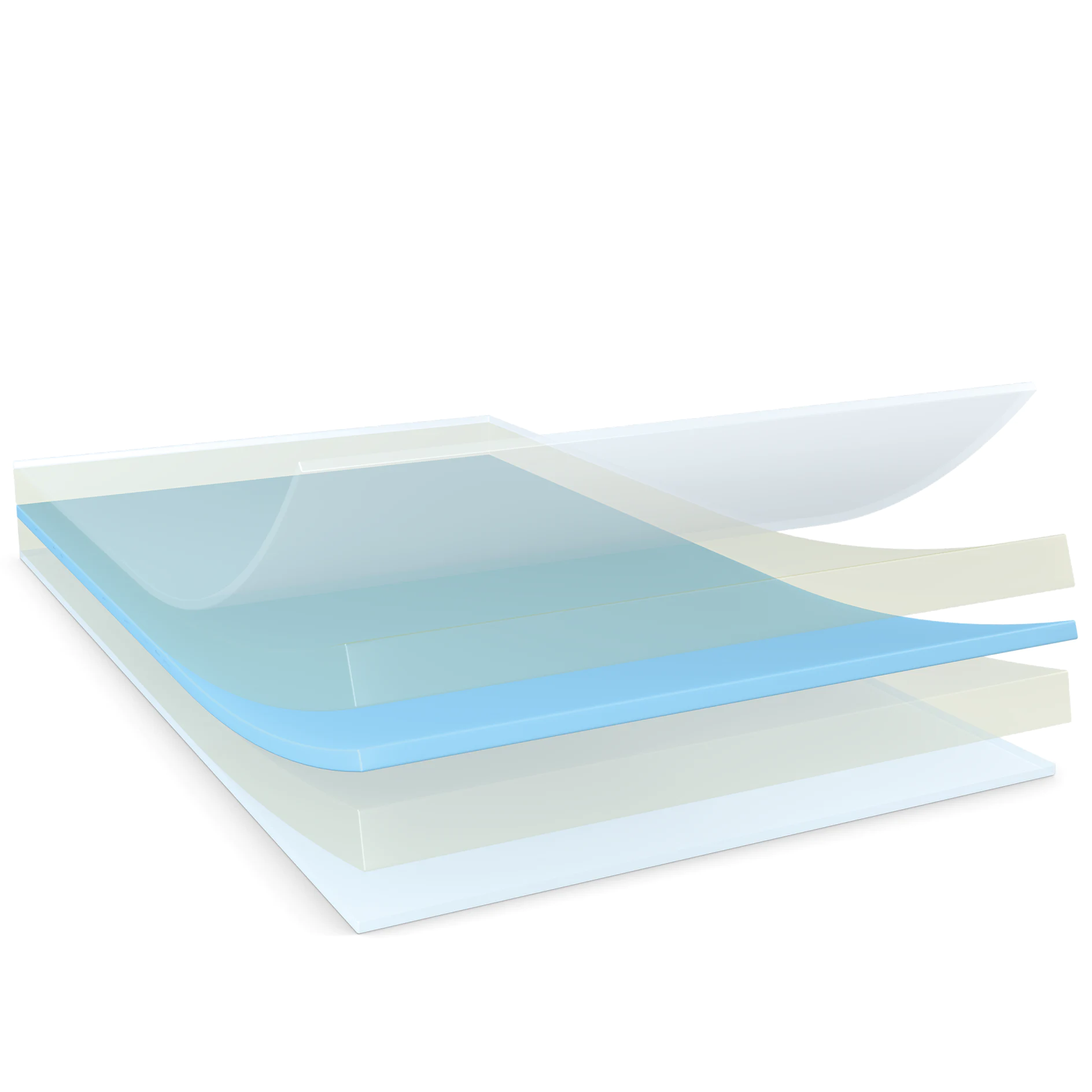

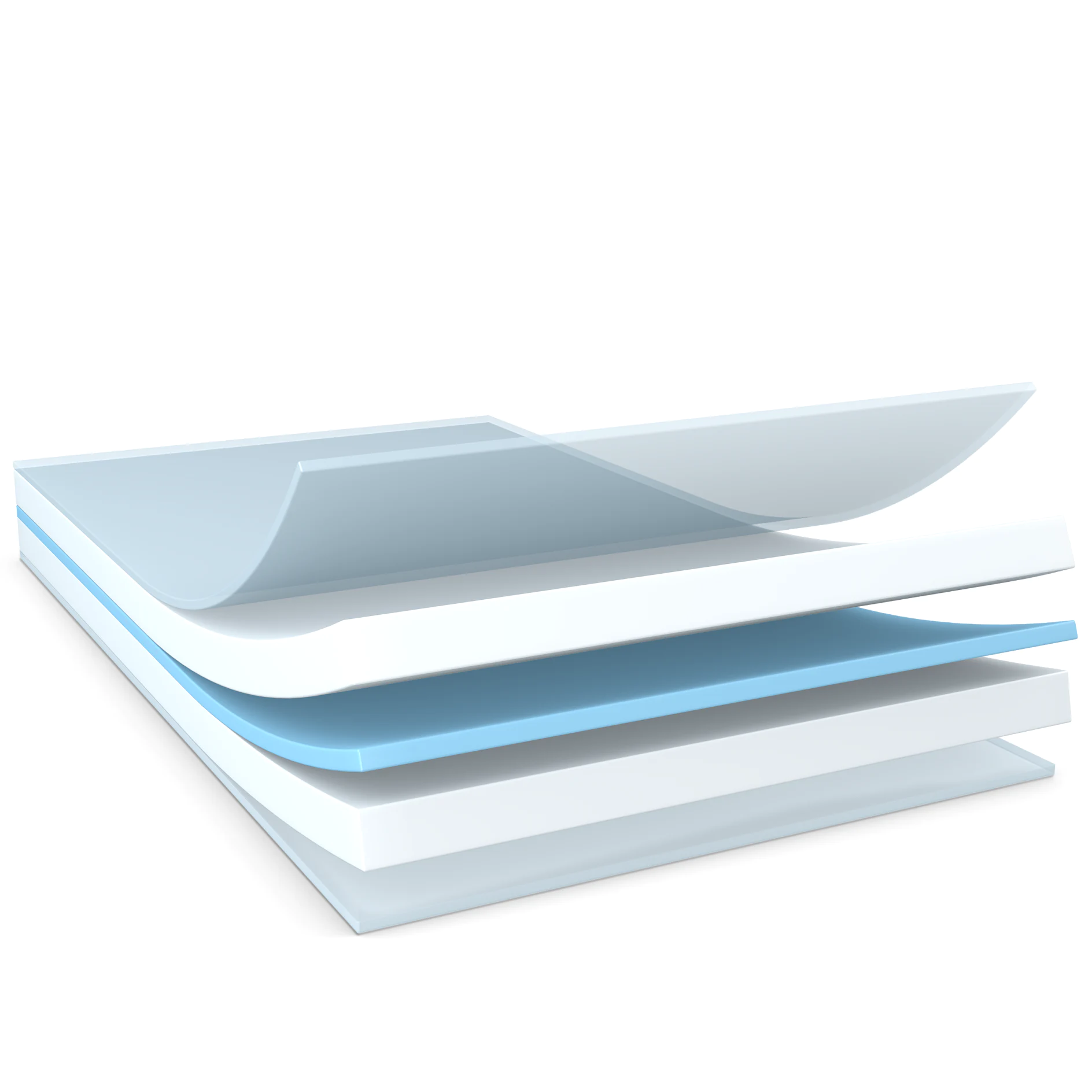

Translucent substrates such as clear plastics can be bonded before activation by light. At least one substrate must be light-permeable to enable the activation of tesa® L-tape. First remove the covering liner of tesa® L-tape and pre-laminate the tape onto the first substrate. The second substrate is then bonded by applying sufficient pressure (≥3 bar). The bonded parts are then exposed to light to start curing of the adhesive.

Pre-lamination conditions

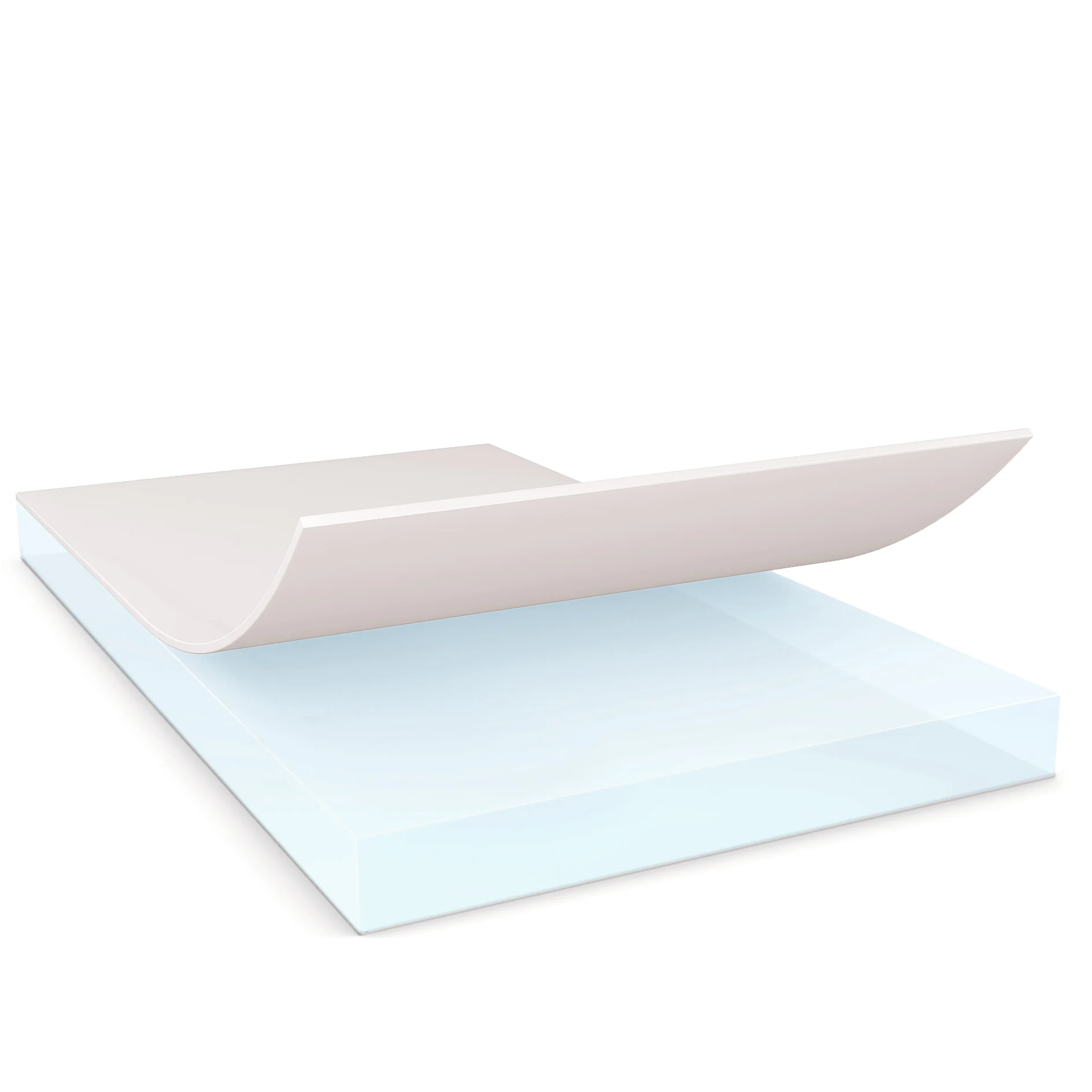

Before curing tesa® L-tape has initial tack and can be pre-laminated like a common PSA tape A pressure of ≥1 bar should be applied to ensure proper wet-out to the surface

Bonding and curing conditions

Bonding of opaque substrates

The open time of tesa® L-tape enables the bonding of opaque substrates like plastics and metals. tesa® L-tape can be activated by light as an die-cut or already pre-laminated onto the first substrate.

Activation of pre-laminated parts: First remove the covering liner of tesa® L-tape and pre-laminate the tape onto the first substrate. The pre-laminated parts are then exposed to light. The second substrate is bonded by applying sufficient pressure (≥3 bar) within 5 min after activation.

Activation of die-cuts: First the die-cut of tesa® L-tape is activated by light. The covering liner of the die-cut must be light-permeable (e.g., clear PET) to enable the activation of the tape. After activation the die-cut is pre-laminated onto the first substrate. The second substrate is then bonded by applying sufficient pressure (≥3 bar). Pre-lamination and bonding must take place within 5 min after activation.

Bonding of translucent substrates

Translucent substrates such as clear plastics can be bonded before activation by light. At least one substrate must be light-permeable to enable the activation of tesa® L-tape. First remove the covering liner of tesa® L-tape and pre-laminate the tape onto the first substrate. The second substrate is then bonded by applying sufficient pressure (≥3 bar). The bonded parts are then exposed to light to start curing of the adhesive.

Pre-lamination conditions

Before curing tesa® L-tape has initial tack and can be pre-laminated like a common PSA tape A pressure of ≥1 bar should be applied to ensure proper wet-out to the surface

Bonding and curing conditions

- Light source: Lamp of 365 nm or 460nm

- Light dose: 20 - 50 J/cm² at 365 nm or 30 - 60 J/cm² at 460nm

- Activation time: ≥30 s

- Pressure: ≥3 bar

- Bonding time: ≥30 s