For example, this wooden container (opens in a new window or tab) used to send gifts could be used as a bird box.

Sustainability

83% of consumers (opens in a new window or tab) claimed unsustainable packaging would be enough to alienate them from a company. This means more sustainable adhesive tapes for industry applications are no longer a “nice-to-have” gesture but a crucial part of customer acquisition and retention.

There are many ways you can enhance your customers’ experience AND deliver the goods by using more sustainable tapes. We’ve examined the latest trends and advancements in packaging, and this article aims to show how you can step closer to your sustainability goals.

Choosing a more sustainable tape or adhesive can mean different things. It can mean the complete eradication of single-use plastics from your packaging materials, or it can mean taking steps to phase out and replace them. One of our sustainability goals is to help make your packaging completely recyclable. (opens in a new window or tab)

We continue to engineer and optimize our tapes to improve the recyclability of your products. This is done by collaborating with you, our clients, and keeping a finger on the pulse of the industry. You’re the expert in what you do, so leave it to us to figure out connecting the pieces in driving sustainability on your packaging. From the tapes that seal your packaging to what you use to secure your goods inside. This is how we approach making more sustainable adhesive tapes for industry settings.

Below is a non-exhaustive list of material alternatives (opens in a new window or tab) that are currently the focus of R&D efforts around the world:

If you are situated or have customers in Europe, you’ll likely be familiar with the EU’s Packaging and Packaging Waste Regulation (PPWR) (opens in a new window or tab). If not, this focuses on reducing the use of single-use plastics and replacing them with reusable and recyclable packaging.

The European Union cites (opens in a new window or tab) the following data backing the introduction of this regulation:

Research suggests (opens in a new window or tab) that Polylactic Acid (PLA) and bamboo are the most likely replacements.

Both PLA and bamboo have attracted substantial investment for R&D in China (opens in a new window or tab), in the efforts to reduce reliance on fossil-based plastics. This attention reflects the nation’s commitment to leading the next generation of environmentally conscious packaging solutions. We keep a close eye on research like this to help develop more sustainable adhesive tapes for industry.

We take optimizing your sustainability more seriously than classifying it as a trend. After all, trends are perceived as temporary change, whereas our commitment to prioritizing sustainability is our guiding force (opens in a new window or tab). That said, it doesn’t hurt to take inspiration from what’s currently popular across industries.

We’ve identified our top 5 sustainable packaging trends you need to know about:

Aligned with one of our core sustainability values, multifunctional packaging embraces product circularity (opens in a new window or tab). This can help improve the sustainability of your operations in two ways:

The concept of multifunctional packaging focuses on inspiring the end user to repurpose it after use. This could be a mailing box with an appealing interior design that can be easily reassembled and used for storage.

For example, this wooden container (opens in a new window or tab) used to send gifts could be used as a bird box.

The beauty of simplicity is two-fold in this trend. Minimalistic packaging is not only an aesthetic. It also uses fewer resources, making it easier to recycle.

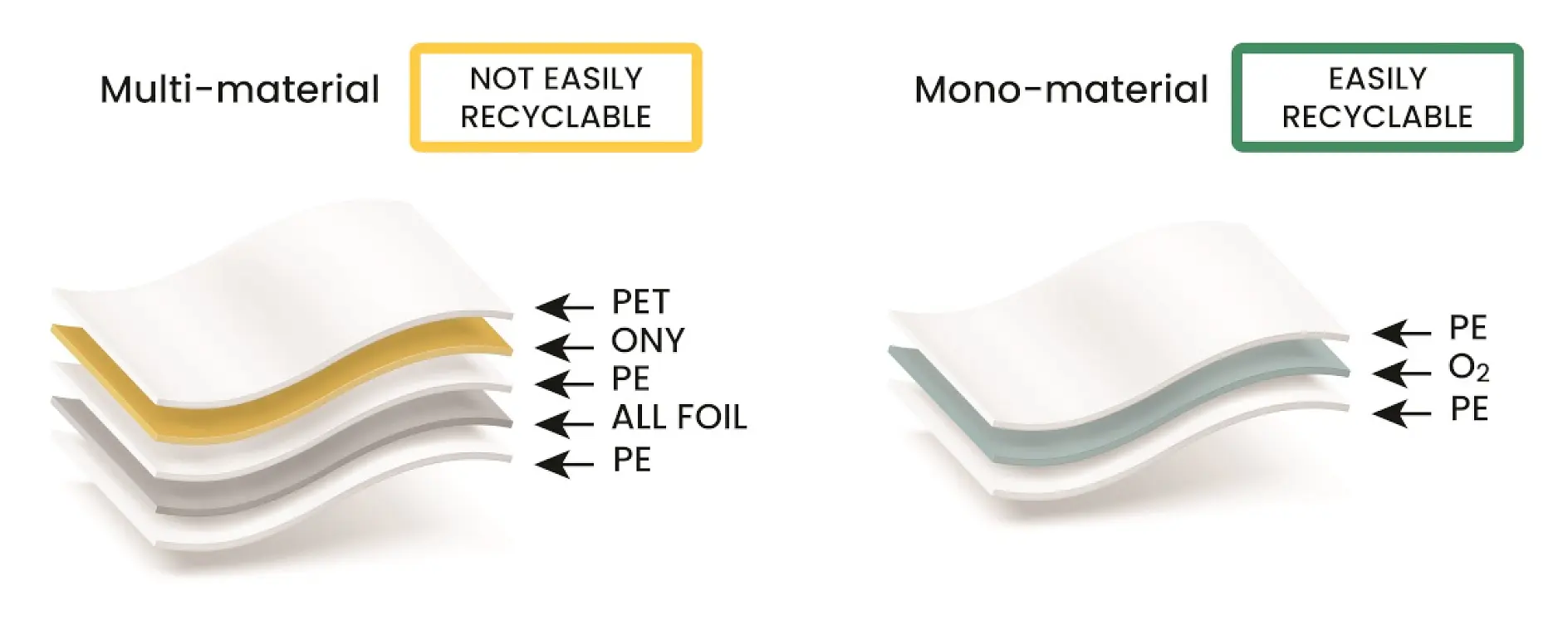

Mono-materials are typically easier to recycle. (opens in a new window or tab) They don’t need to be disassembled before recycling. Mono-materials are also compatible with common, existing recycling streams. Additionally, it takes less energy to recycle, which further reduces environmental impact.

Examples of mono-materials include:

This example (opens in a new window or tab) uses kraft boxes with soy-based ink and a cut-out window. This packaging is 100% recyclable.

Let’s not overlook the adhesives used here, as it has the power to make or break your sustainability efforts. Paper-based closing tapes, like tesa® 61346 (opens in a new window or tab), allow cardboard closures to be recycled without having to be removed.

Although these two terms are often used interchangeably, they are not the same. Let’s look closer to help identify the differences:

Biodegradable products can be made from any material that breaks down over an unspecified period. Technically, all materials are biodegradable.

Sometimes, ‘biodegradable’ infers a product is made from bio-based materials, but this doesn’t have to be the case. This makes it a little trickier to regulate.

Compostable products rapidly break down, leaving no toxicity behind, when disposed of in a composting environment. For a product to be described as ‘compostable,’ it needs certification (opens in a new window or tab).

Examples of compostable packaging materials include:

It is important to research and understand the materials used in packaging. For example, home composting isn’t as efficient as industrial composting (opens in a new window or tab), where temperatures and conditions are controlled to optimize this process. Additionally, as a business, you’ll need to be able to back up your claims that the materials you are using are certified as compostable.

The implementation of the EU’s PPWR and the UK’s Extended Producer Responsibility (EPR) is driving this swap from plastics to paper-based products. There are many incentives here. For starters, paper is already a well-established recycling stream globally. Plus, economic incentives (opens in a new window or tab) with less need for compliance costs and plastic-related penalties.

Consumers want change (opens in a new window or tab). Their demand: replace petrochemical plastics with more sustainable materials. More businesses are shifting towards bio-based and renewable materials in packaging in response.

Bio-based packaging materials are made from renewable biological materials instead of fossil fuels. Examples include corn (i.e., polylactic acid or PLA), sugarcane (i.e,. bio-based polyethylene or PE), and mushrooms (i.e., mycelium).

“Pro tip for brands: Communicate your sustainability efforts clearly. Consumers love knowing how their choices make a difference, so don’t be shy about showcasing your eco initiatives on your packaging.”

Packaging Digest

Regardless of how your sustainability transformation looks, it makes sense to include more sustainable tapes and adhesives. Using more bio-based or recycled materials helps you accomplish a more sustainable company. One roll at a time.

We’re tackling this crucial challenge to transform the packaging world with vigour. The demand for more sustainable adhesive tapes for industry use continues to grow. We want you to be part of our journey. Our customers inspire us to drive change and develop the most innovative solutions to everyday problems.

tesa® 60412 Recycled PET packaging tape (opens in a new window or tab) is part of our (opens in a new window or tab)more sustainable (opens in a new window or tab) range. Starting as a transparent tape with 70% PCR recycled plastic in the backing, and has continued to evolve, now containing 90%. Same great performance, same great price - now with more PCR PET.

Sellpy (opens in a new window or tab) needed an eco-friendly packaging tape that they could integrate without disruption. We worked in collaboration with them and their packaging partner, aPak, to develop tesa® 4713 (opens in a new window or tab). (opens in a new window or tab) This tape comprises of paper sourced from controlled forests and natural rubber adhesive made from renewable feedstock.

What's more, Sellpy told us they need less tape to secure their boxes since switching to tesa® 4713. (opens in a new window or tab) This added benefit means they're also using fewer resources too!

On the theme of continuous product optimization, all tesa® paper carton sealing tapes are now FSC®-certified! tesa® 60013 in particular is a standout example. This reinforced paper packaging tape was developed for heavy-duty packaging using innovative fiber-glass reinforced paper backing tape. When compared to similar specification filmic packaging tapes, it offers outstanding performance, and it can be recycled along with cardboard packaging, according to INGEDE Method 12 (opens in a new window or tab).

As an adhesives manufacturer, there are many common challenges we and our customers face. You’re avoiding or reducing excessive packaging (opens in a new window or tab). You want to be able to recycle or at least use more sustainable packaging where possible. And for us it’s the same. There are really only two options for us: give up or rise to the challenge. We choose the latter (opens in a new window or tab).

We don’t just manufacture packaging; we use it for our 7,000+ portfolio. We use it to protect our goods from dust, dirt, or damage in storage and in transit. So to say we understand your challenges around reducing your impact on the environment couldn’t be more true.

Prioritizing sustainability is a guiding principle. As a global company, manufacturer of adhesives, and an employer, it’s paramount to help create a more sustainable future (opens in a new window or tab). Our HQ Packaging Development team in China has successfully implemented a service to collect and reuse our polystyrene end walls (opens in a new window or tab). This is just one example of our holistic approach to sustainability and pushing circularity in our own operations.