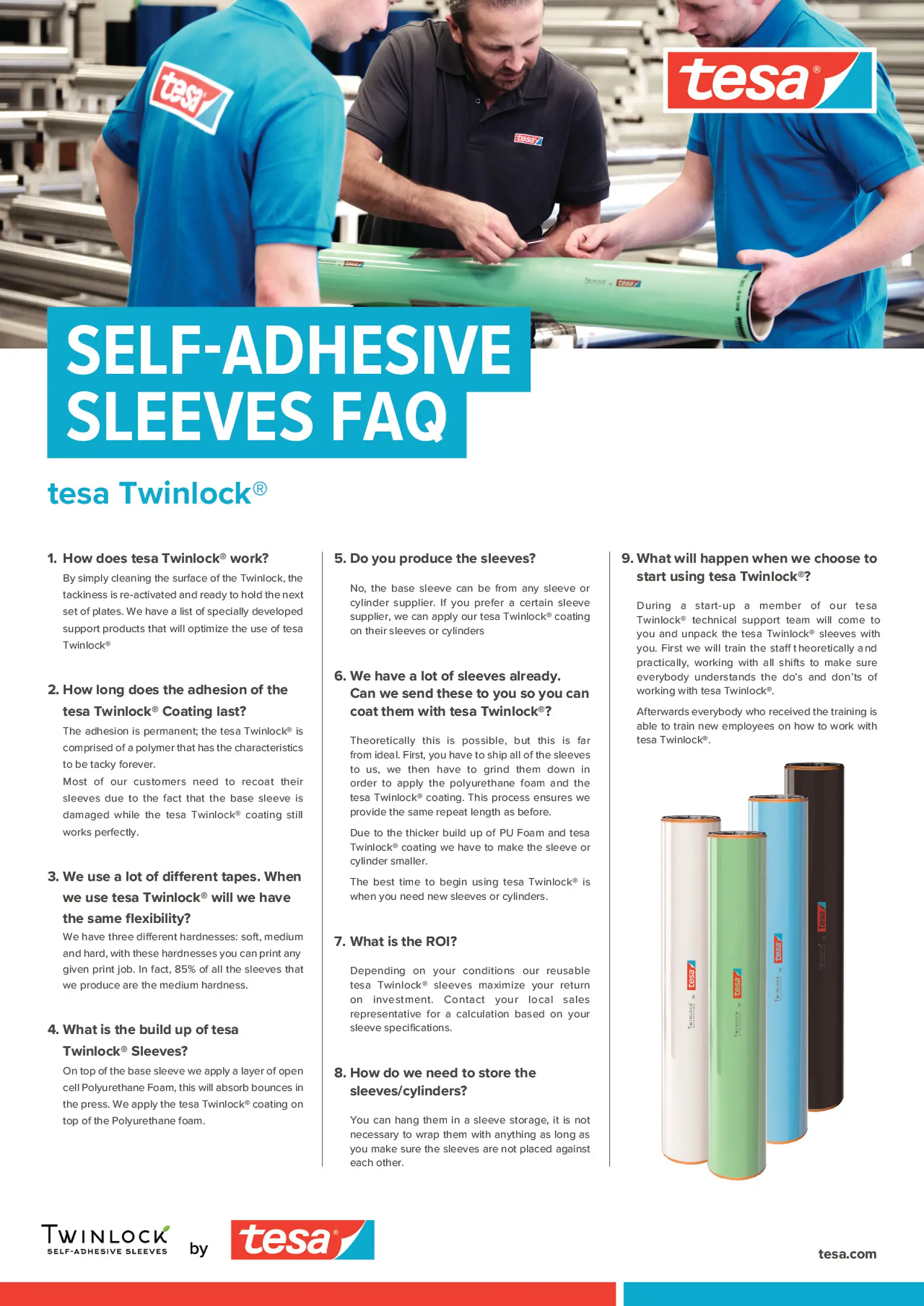

tesa® Twinlock is a reusable, self-adhesive and compressible plate mounting sleeve - the printing plate can be directly mounted on the sleeve. After printing and plate removal, the tackiness can simply be re-activated, making the sleeve ready for the next job.

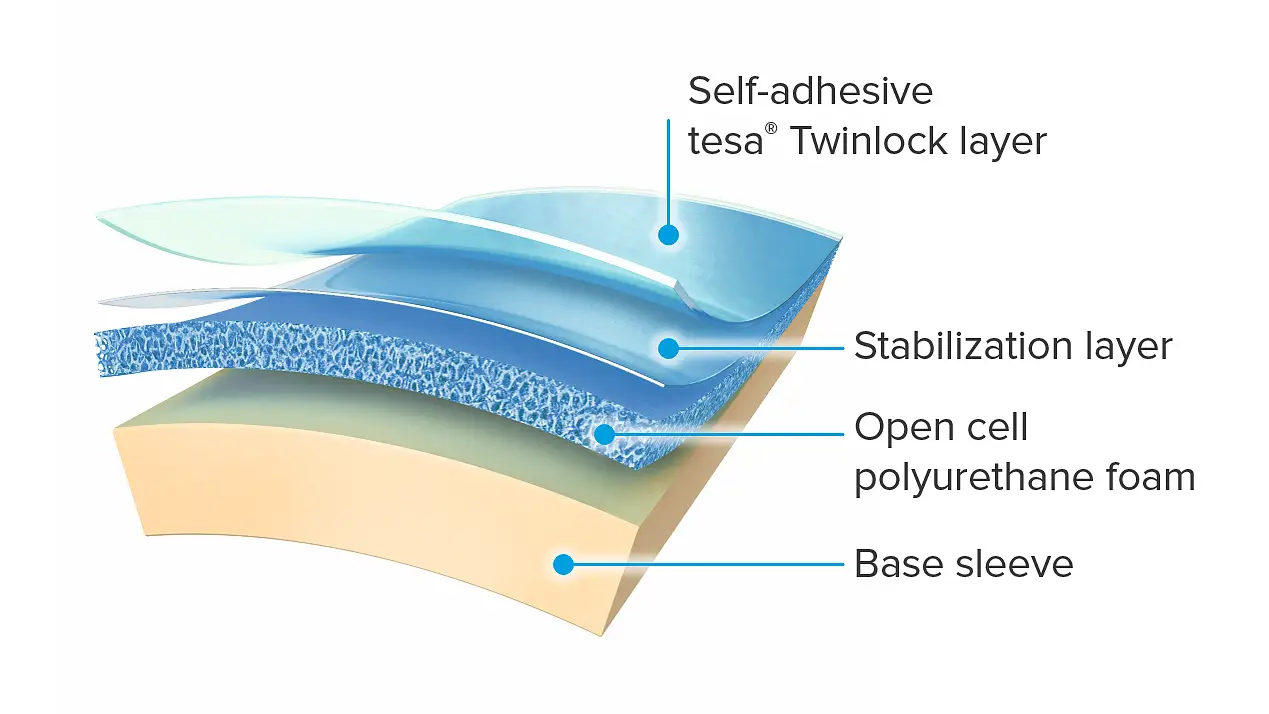

Our PRODUCT DESIGN:

Let us know your preffered sleeve type and we take that sleeve and add a layer of polyurethane (PU) foam, a stabilization film layer, and then a layer made from a polymer that is formulated to retain its adhesive qualities.