The quality of our assortment

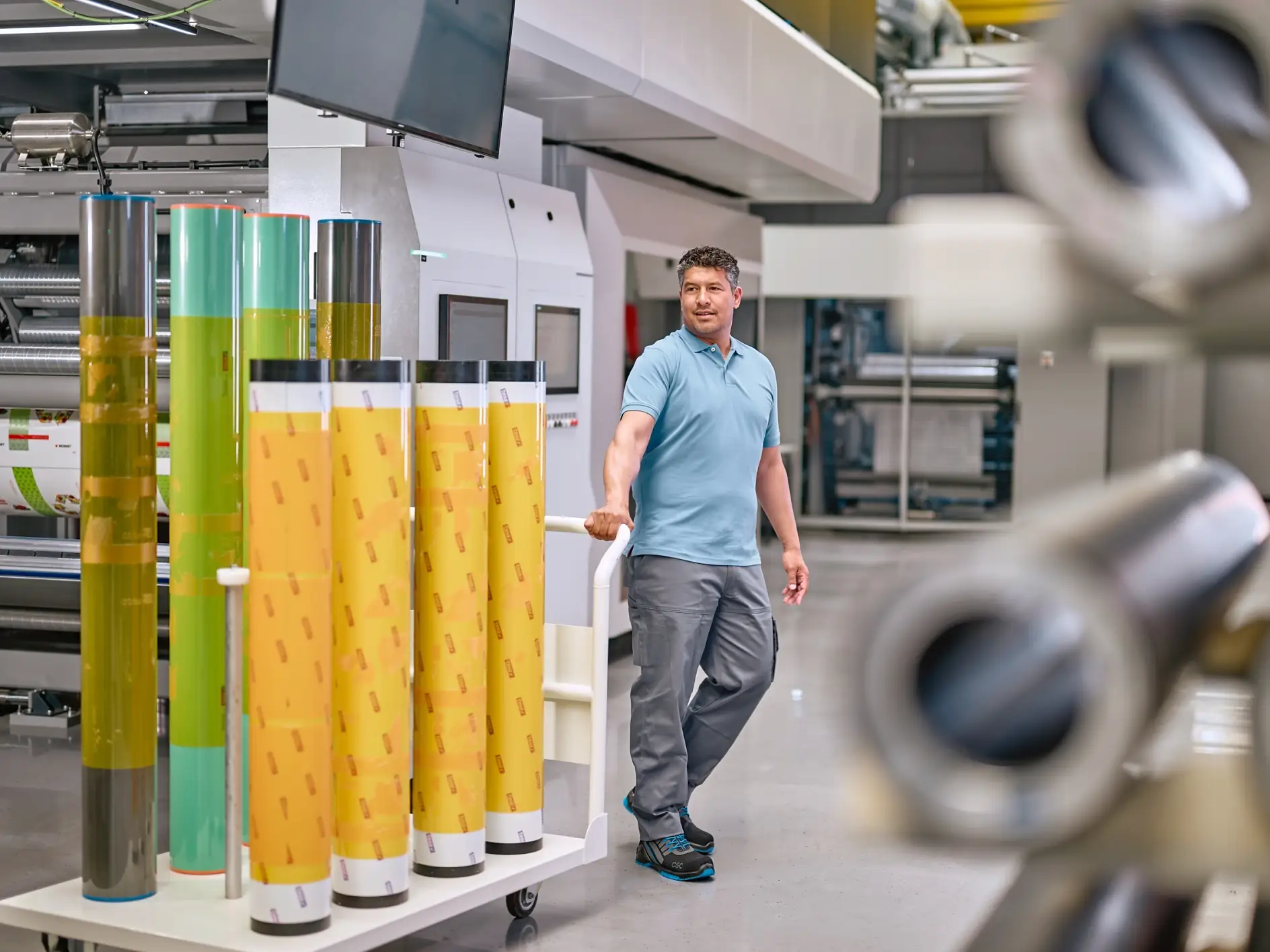

No other flexo supplier provides such a unique choice of first class plate mounting solutions. With tesa® Twinlock and tesa® Softprint, we offer a complete range of tape and re-usable self-adhesive sleeves. All raw materials we use are of highest quality and our decades of expertise in manufacturing self-adhesive solutions ensure stable quality every time. The production process of our tesa® Softprint tapes for example ensures that no stress is applied to the foam, leaving all cells intact for resilience during printing. When producing tesa® Twinlock, tailored laser measuring devices ensure exact repeats for every print job.