A new dimension of

design freedom for

consumer electronic devices!

The new light-curing structural bonding tape:

tesa® L-tape

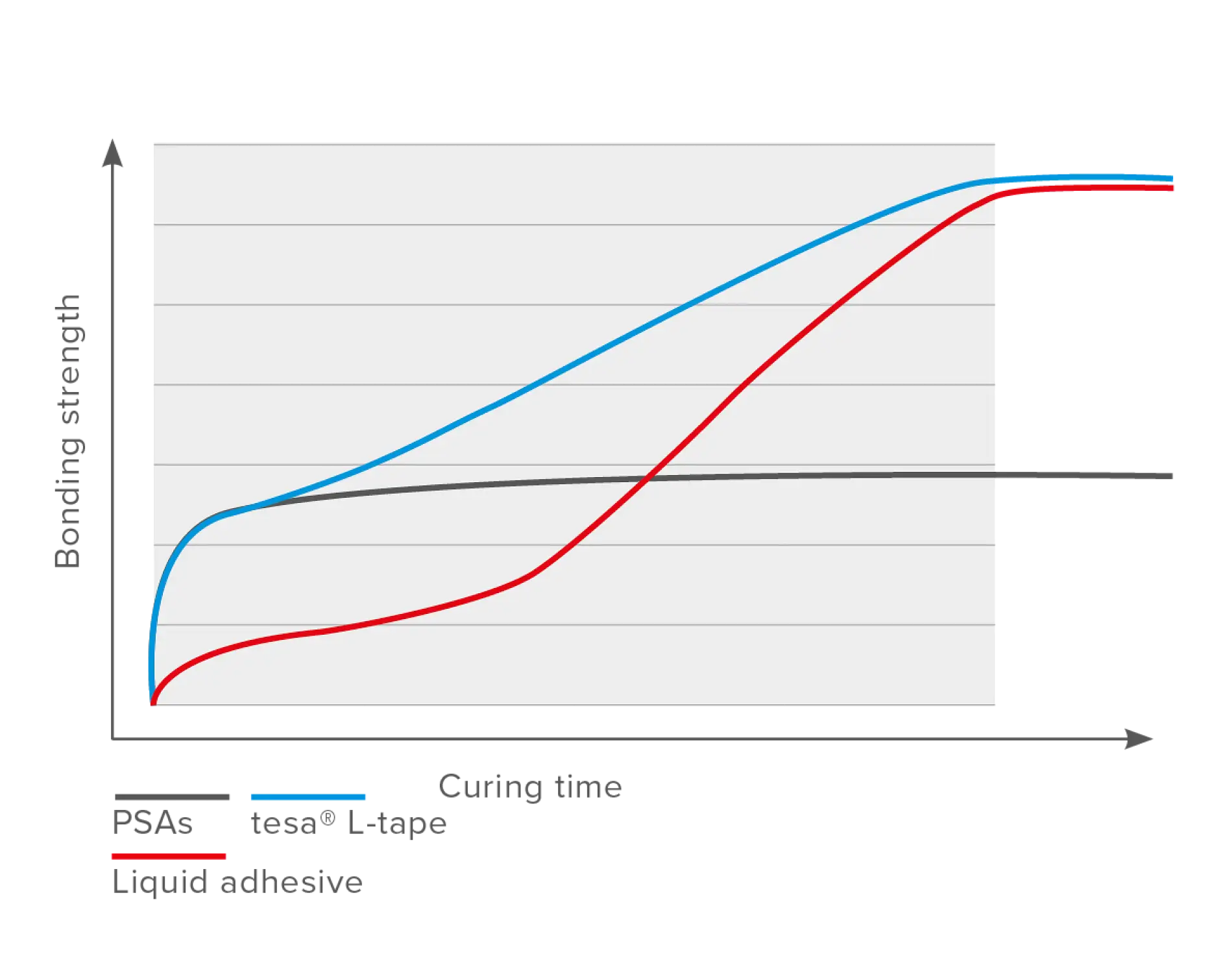

tesa® L-tape empowers you to overcome the limitations of current adhesive technologies. The unique combination of structural bonding strength and PSA-like handling, enabled by the innovative light-curing feature at room temperature, delivers outstanding performances.

The best of both

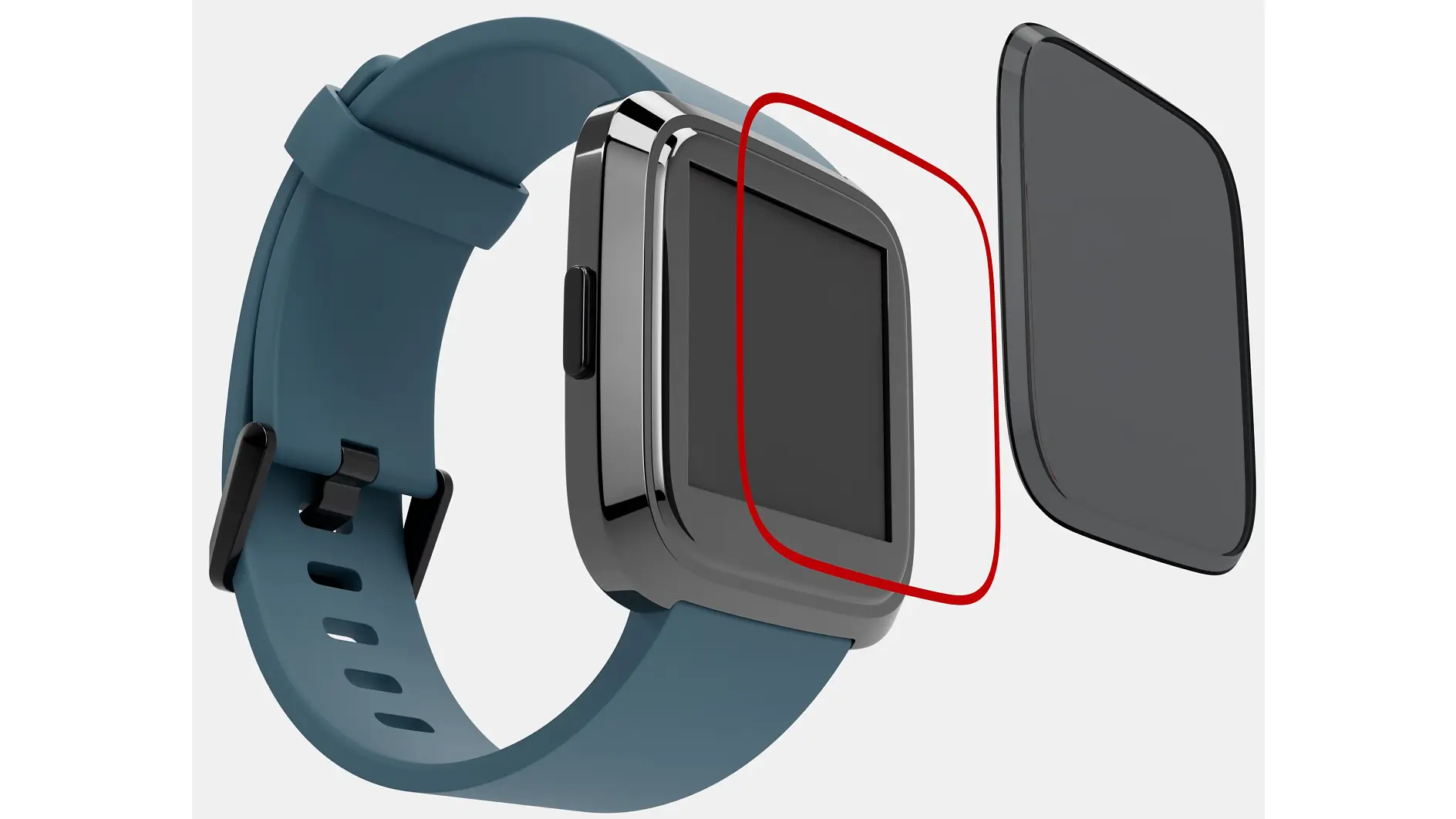

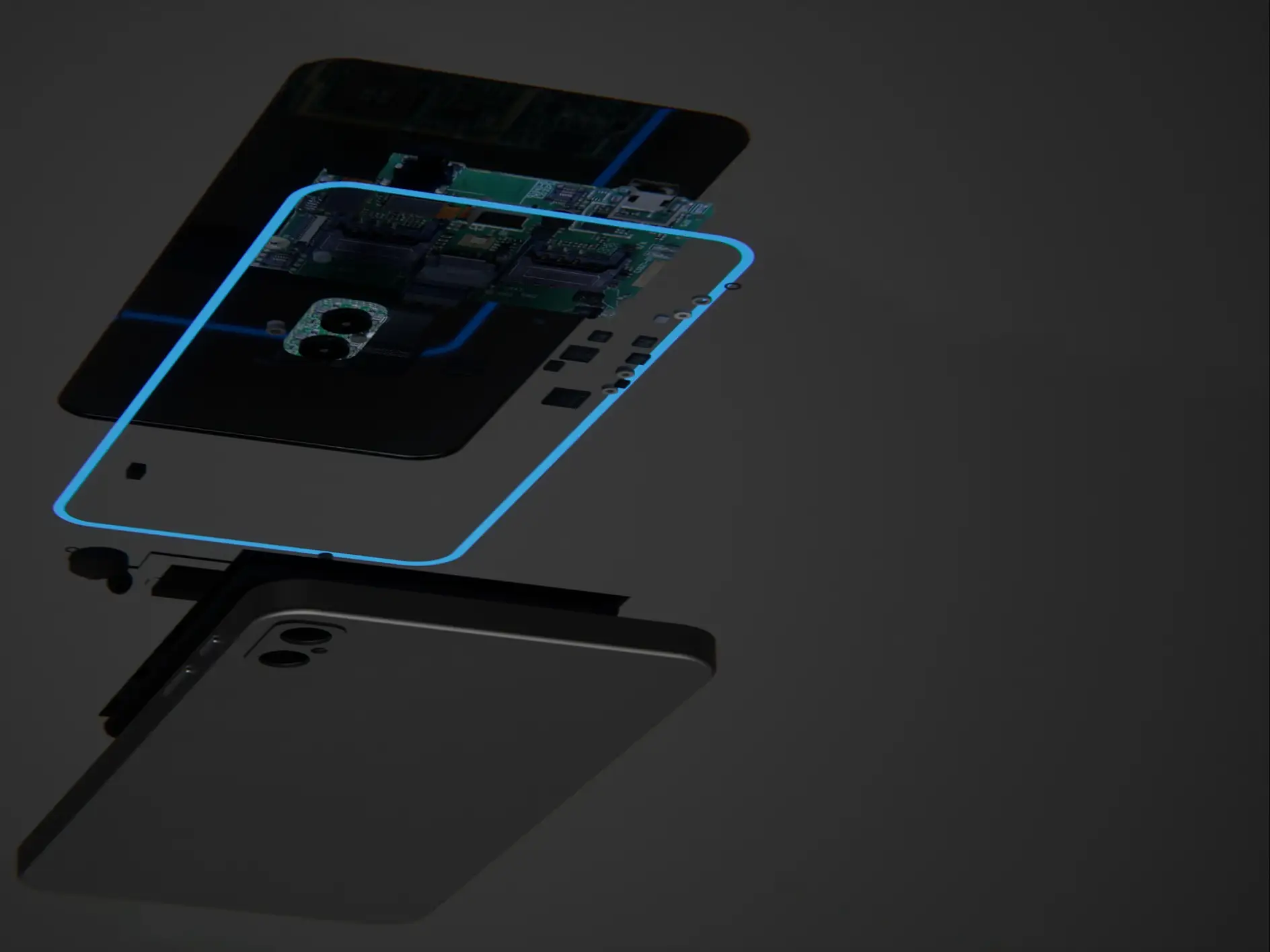

As bonding areas become smaller and slimmer due to design trends in electronic devices, requirements for adhesives in terms of high and reliable bonding strength continuously increase.

While liquid adhesives can provide high ultimate bonding strengths, they come with some processing challenges like ooze cleanup, long curing times, and uneven coverage after curing.

On the other hand, filmic PSAs can be conveniently applied in the required shapes and geometries and provide high immediate bonding strength directly after joining but usually do not reach the same high adhesive strength as liquid adhesives.

tesa® L-tape now combines the strengths and advantages of both PSA tapes and liquid adhesives!

Download whitepaper and learn more!

tesa® L-tape -

the innovative light-curing structural adhesive

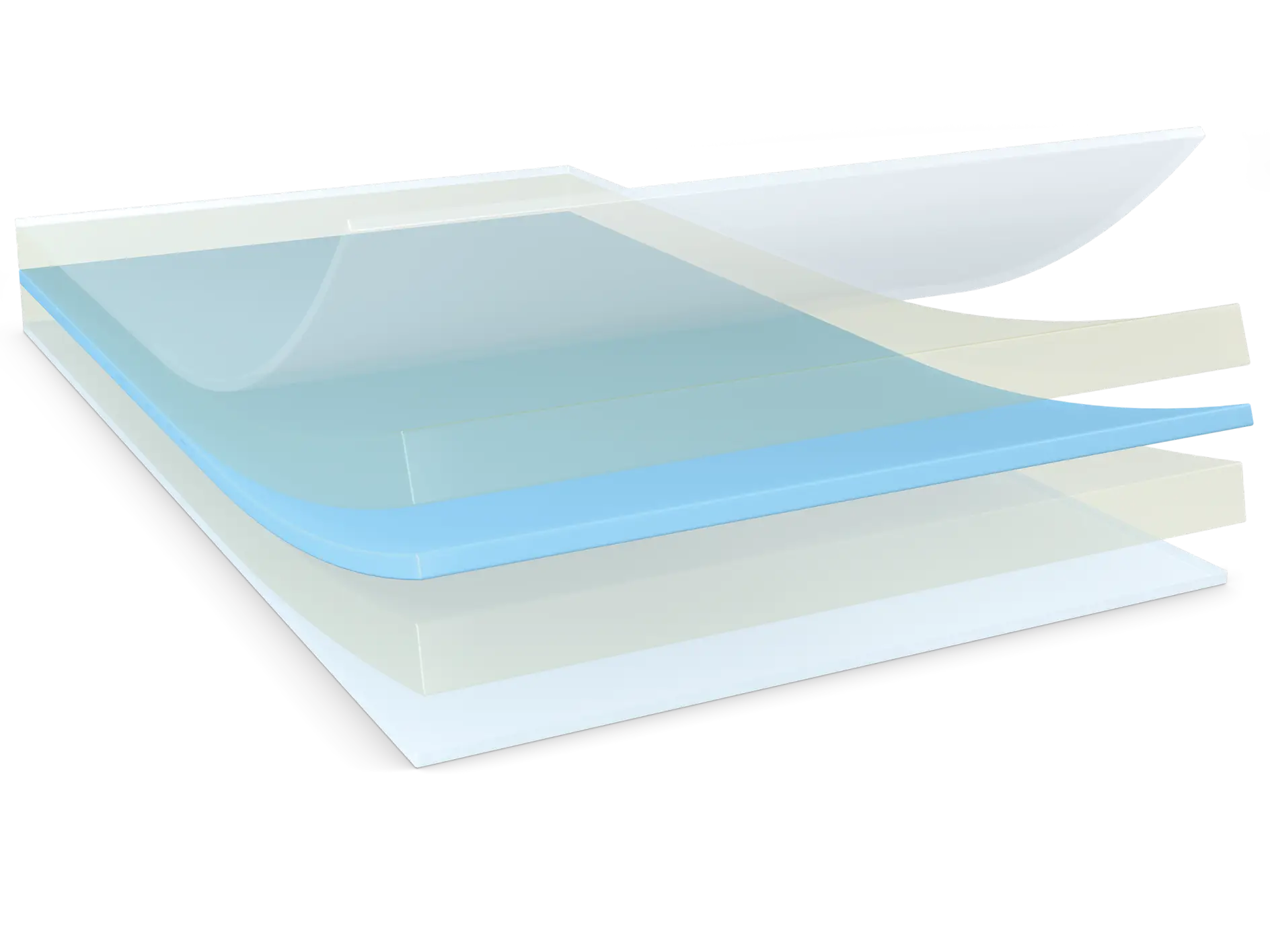

- Double-sided translucent structural bonding tape

- Reactive adhesive offerings very high tack and immediate bonding width

- 3-layer design with a backing included facilitates the processing of narrow and complex die-cut geometries

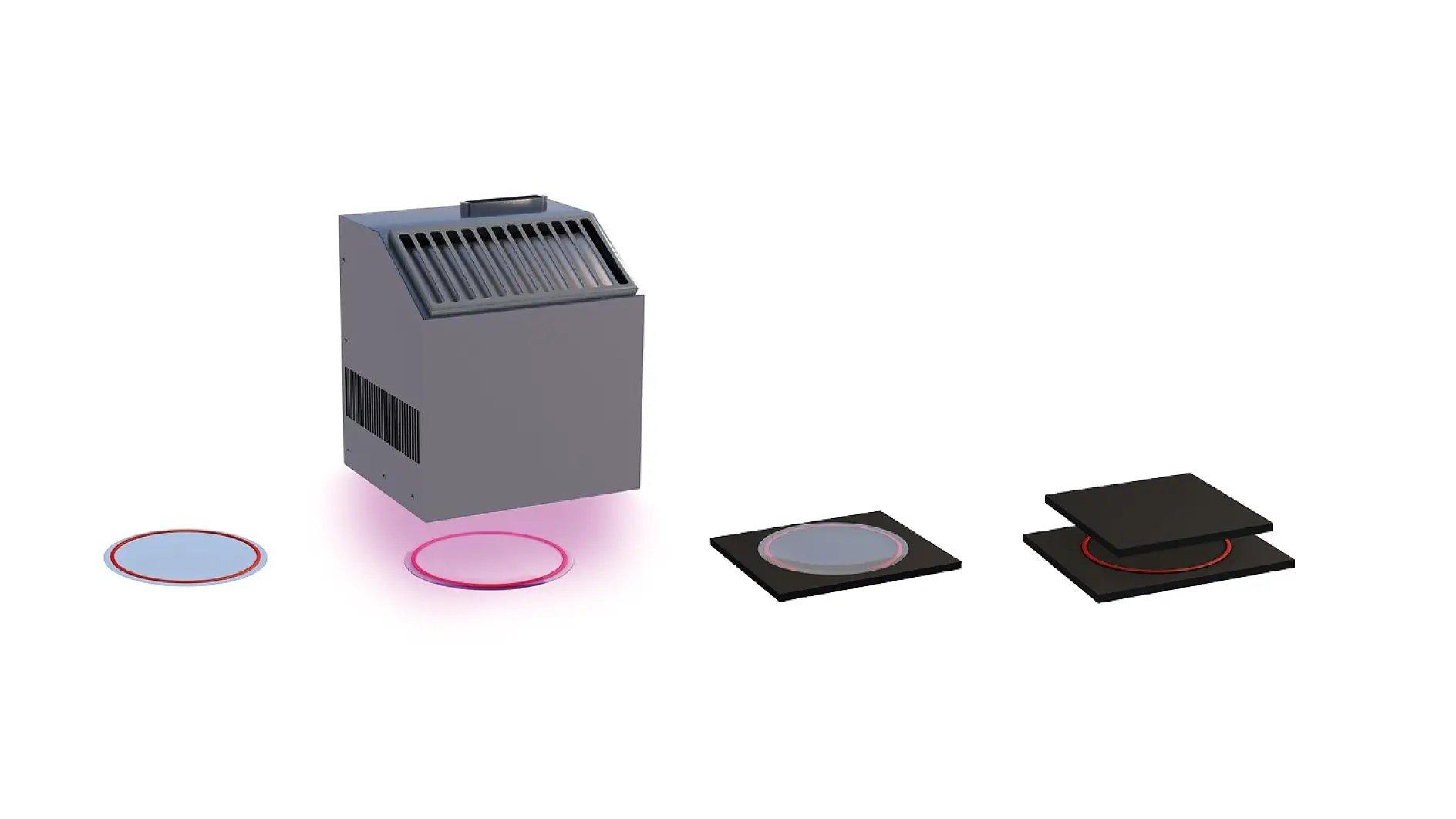

- Activation of room temperature by light enables usage of temperature-sensitive substrates

Rely on superior bonding performance

Once activated the bonding strength of tesa® L-tape is increasing quickly and reaches its very high maximum within 24 hours. The structural bonding solution provides a good performance on a variety of different substrates and is resistant to harsh environmental conditions and chemical substances.

| Product | tesa® L-tape 8694 | tesa® L-tape 8698 |

|---|---|---|

| Thickness [μm] | 100 | 200 |

| Color | Translucent | Translucent |

| Adhesive | Reactive acrylate adhesive | Reactive acrylate adhesive |

| Backing | PET | PET |

| Activation temperature | Room temperature by light | Room temperature by light |

| Lap shear on PC/PC [MPa] | 5.0 | 7.0 |

| Lap shear on Al/Al [MPa] | 8.5 | 9.0 |

| Lap shear on SUS/SUS [MPa] | 10.0 | 11.0 |

| Push-out on PC/PC [MPa] | 5.1 | 7.2 |

| Push-out on Al/Al [MPa] | 6.2 | 7.5 |

| Push-out on SUS/SUS [MPa] | 5.3 | 6.7 |

Flexibility in the manufcaturing process

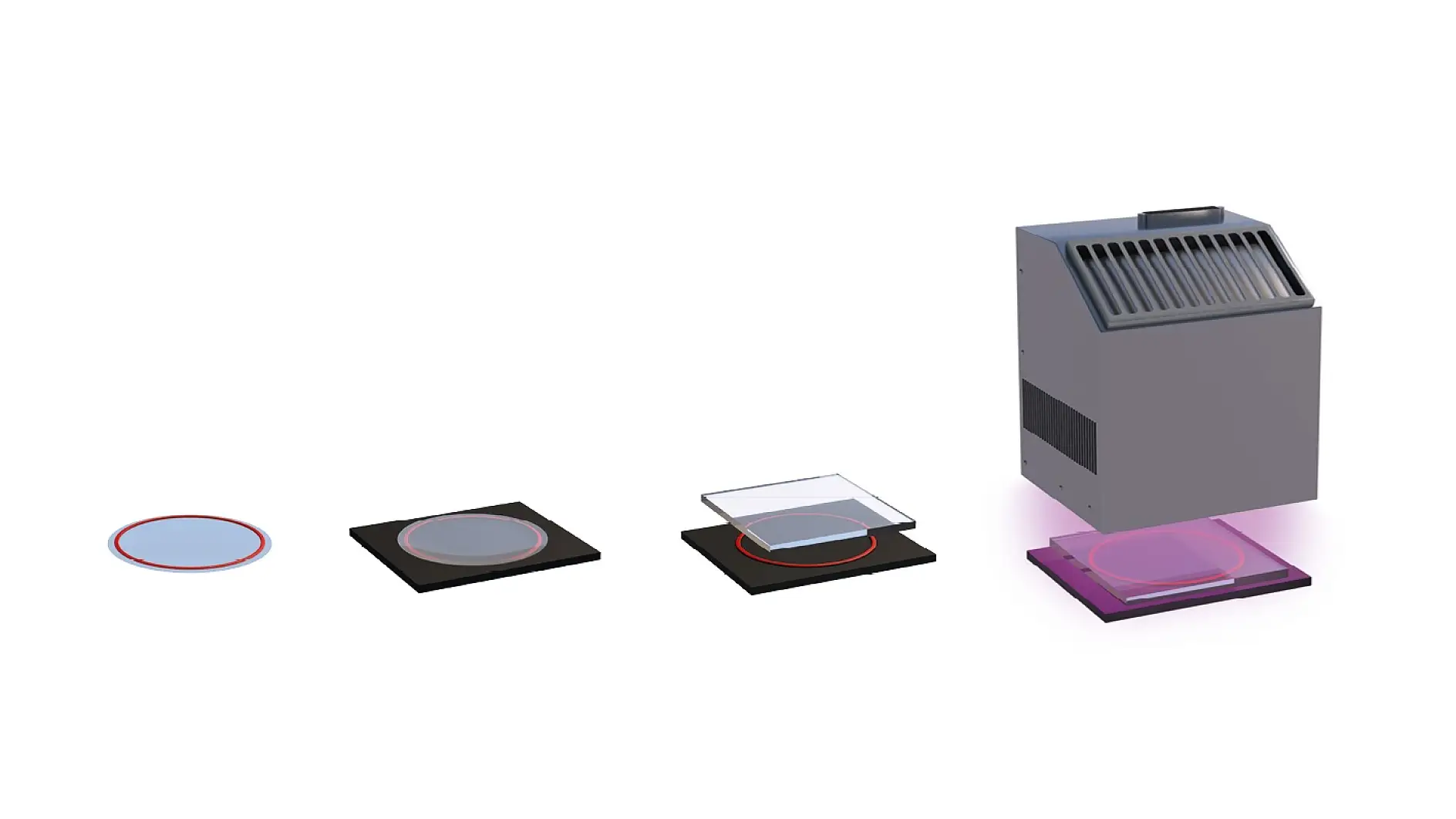

Simplify your manufacturing processes with tesa® L-tape. It is very easy to convert and apply due to its dimensional stability. You don't need additional equipment or fixation as the tape provides immediate bonding strength after application. This way a safe handling of bonded parts is ensured.

In addition, the open time of 5 minutes after initiation provides the maximum flexibility for your manufacturing processes.

tesa® Structural bonding solutions - Activation of tesa® Light-curing tapes (1)

Curious to learn more?

In accordance to our privacy policy, your data will only be stored in a manner appropriate to the nature of the request to fulfill your needs.