Faster and more efficient manufacturing, converting, and processing of film materials calls for changes in raw materials and production processes.

One of the resulting aspects is the use of high slip agents to reduce the film’s coefficient of friction (COF) and ensure sufficient slip characteristics of produced films, for example in Bi-axially Oriented Polypropylene (BOPP) or High and Low Density Polyethylene (HDPE/LDPE) films. The most common slip additives are organic waxes such as erucamide and oleamide.

Surface friction occurs between individual layers of the film material or between the film and the processing equipment and can result in issues when winding reels of film, when converting the film (e.g. bag production), or during packaging processes of final goods. To make high-speed processes possible, slip agents are added to the polymer during extrusion as a cost-effective solution to the problem of friction.

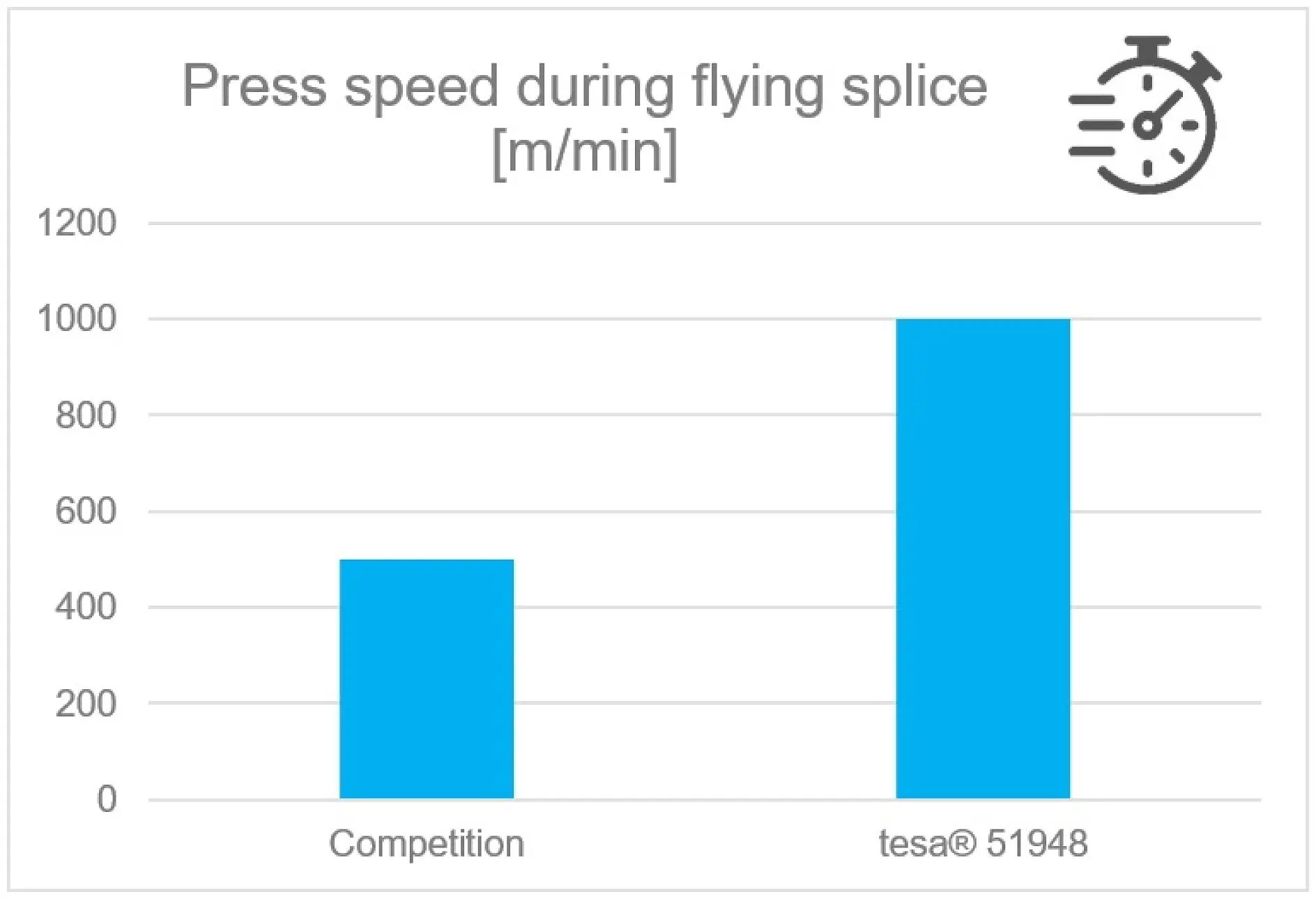

But the use of slip agents within film substrates does not only cause advantages. The printability of the film material can be effected and a limited performance of splicing tapes can lead to an enormous reduction of efficiency due to reduced machine speeds or web breaks.

The root cause for these issues are the slip agents which continuously migrate onto the film´s surface. Here they create a “boundary layer” which reduces the wetting effect of a splicing tape. The limited bond between film and splicing tape can then result in an unsuccessful splicing process.